5-151

5-11 Sensorless Vector Control

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-Axxxx)

5

Functions

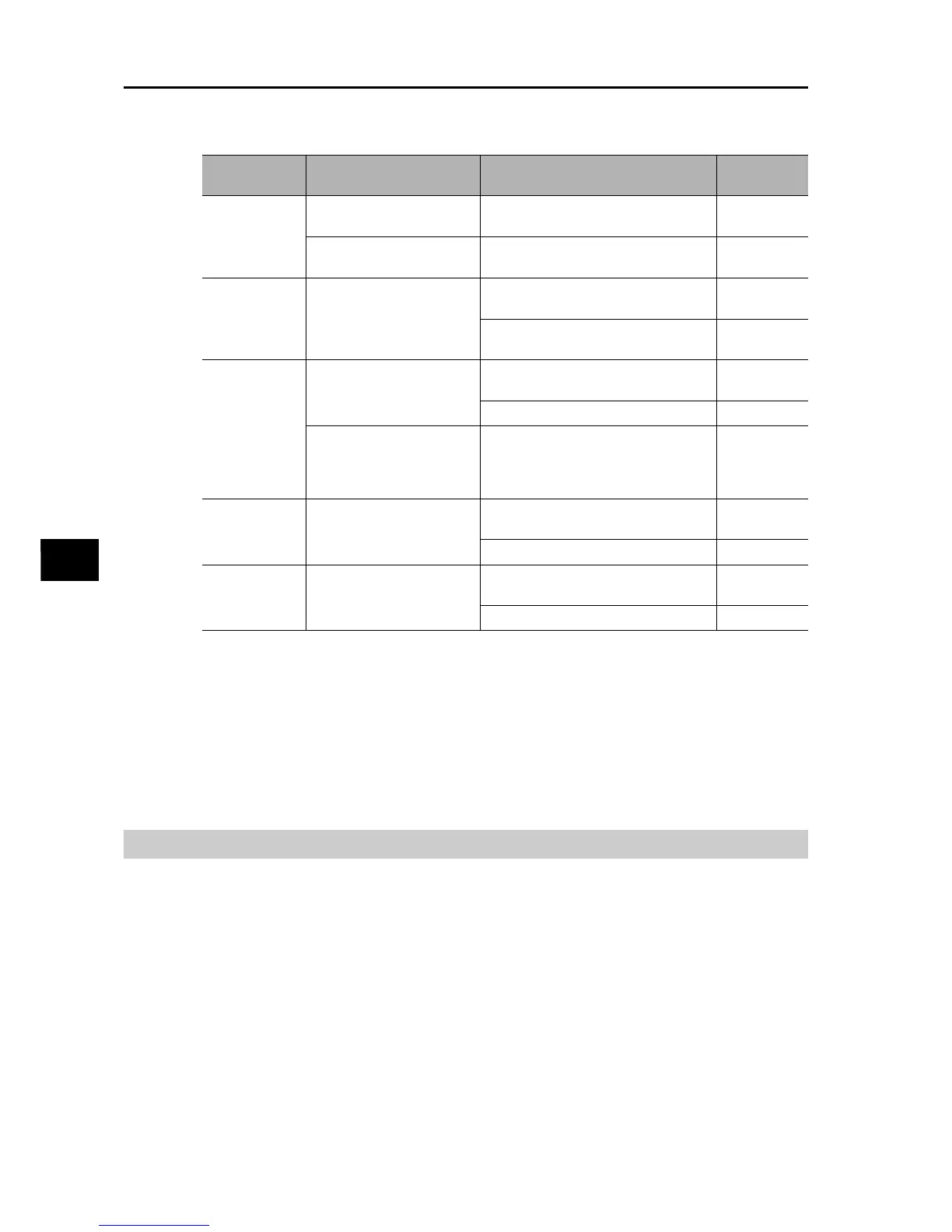

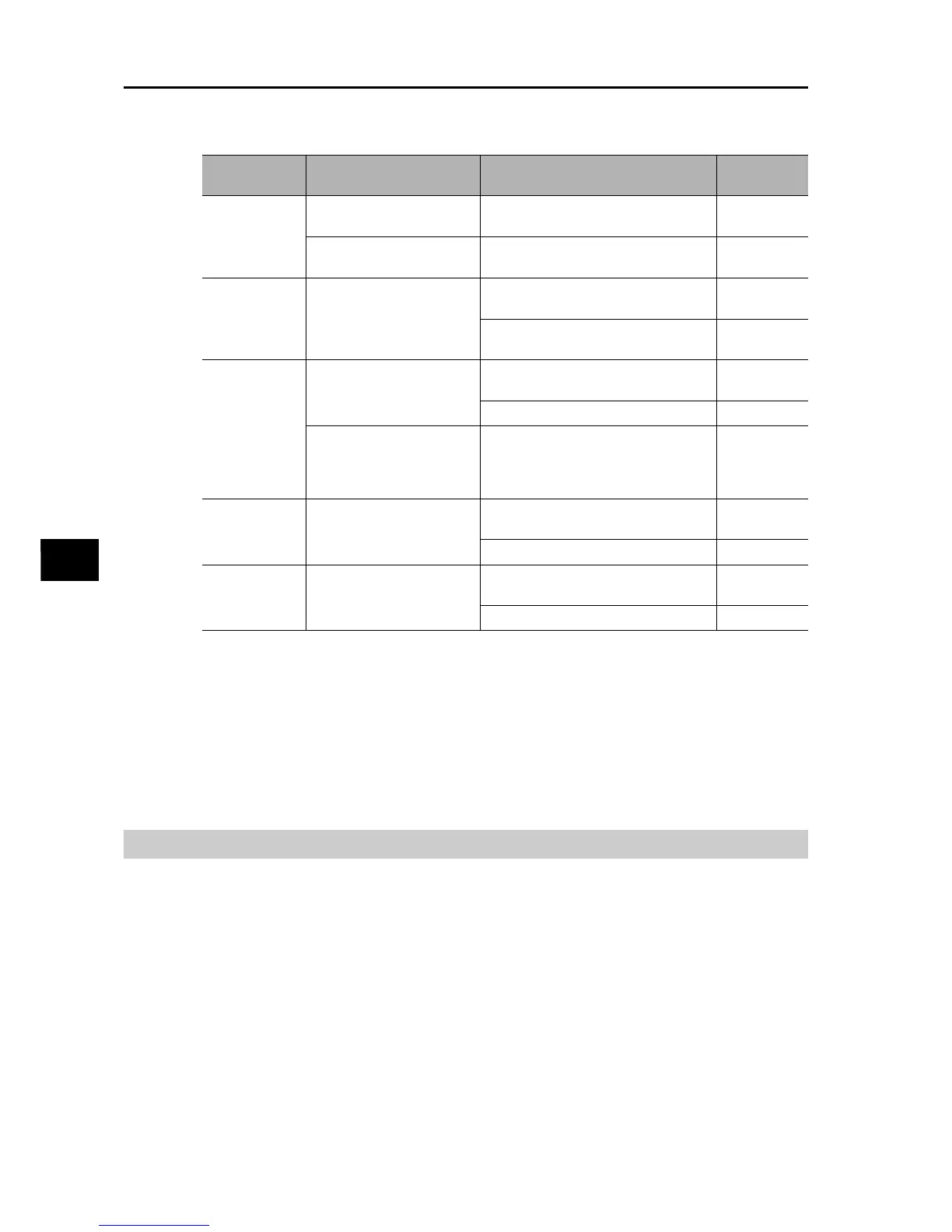

If sensorless vector control cannot provide the desired characteristics, adjust the motor

parameters depending on the phenomena, as shown in the table below.

Note: To use a motor with a capacity lower than that of the Inverter, set Torque Limit (b041 to b044) by

making sure the value α, calculated with the following formula, does not exceed 200%. Otherwise,

the motor may burn out.

α = Torque limit value × (Inverter capacity) / (Motor capacity)

Example) From the above formula, the torque limit value to achieve α = 200% with a 0.75 kW Inverter and

0.4 kW motor is calculated as follows:

Torque Limit (b041 to b044) = α × (Motor capacity) / (Inverter capacity)

= 200% × (0.4 kW) / (0.75 kW) = 106%.

Torque Monitor Function

This function monitors the estimate output torque of the motor.

This function is enabled only when Sensorless Vector Control is selected for control method

(A044/A244 = 03). Take note that if constant torque characteristics (VC), reduced torque

characteristics (VP 1.7th power) or free V/f setting is selected for Control Method (A044/A244),

this function is disabled and the output signals for display or through the control terminal block

become indeterminable.

To perform monitoring via the Digital Operator, select Display Parameter d012.

To perform monitoring using signals from the control terminal block, refer to "MP Terminal

(Pulse/PWM Output)" on page 5-42 or "AM Terminal (Analog Output)" on page 5-44.

The torque monitor value under this function assumes that the torque corresponding to the

Inverter's rated current is 100%.

Accordingly, the absolute value of torque varies depending on the motor to be combined.

Operation

status

Phenomenon Adjusting method

Adjustment

item

Power running

Speed change ratio is a

negative value.

Increase motor parameter R2

gradually up to the set parameter × 1.2.

H021/H221/

H031/H231

Speed change ratio is a

positive value.

Decrease motor parameter R2

gradually up to the set parameter × 0.8.

H021/H221/

H031/H231

Regeneration

Insufficient torque at low

frequency (several Hz)

Increase motor parameter R1

gradually up to the set parameter × 1.2.

H020/H220/

H030/H230

Increase motor parameter Io gradually

up to the set parameter × 1.2.

H023/H223/

H033/H233

During startup

Shock occurs during

startup.

Reduce motor parameter J from the set

parameter.

H024/H224/

H034/H234

Reduce the speed response. H005/H205

The motor momentarily

rotates in the direction

opposite the reference

rotation direction.

Set Reverse Rotation Prevention

Selection (b046) to "01: Enabled."

b046

During

deceleration

Motor hunting

Reduce motor parameter J from the set

parameter.

H024/H224/

H034/H234

Reduce the speed response. H005/H205

Low-frequency

operation

Rotation is not constant.

Increase motor parameter J from the

set parameter.

H024/H224/

H034/H234

Raise the speed response. H005/H205

Loading...

Loading...