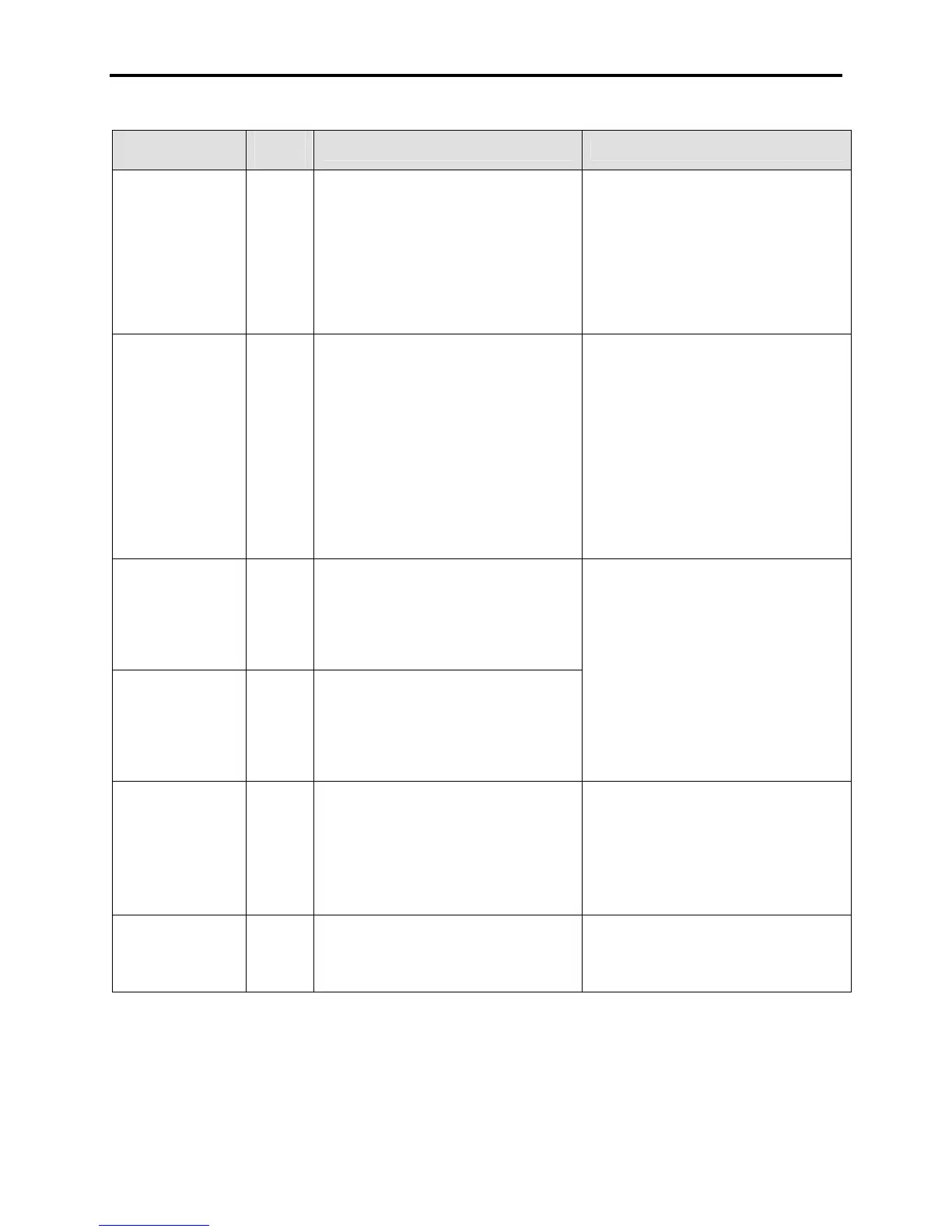

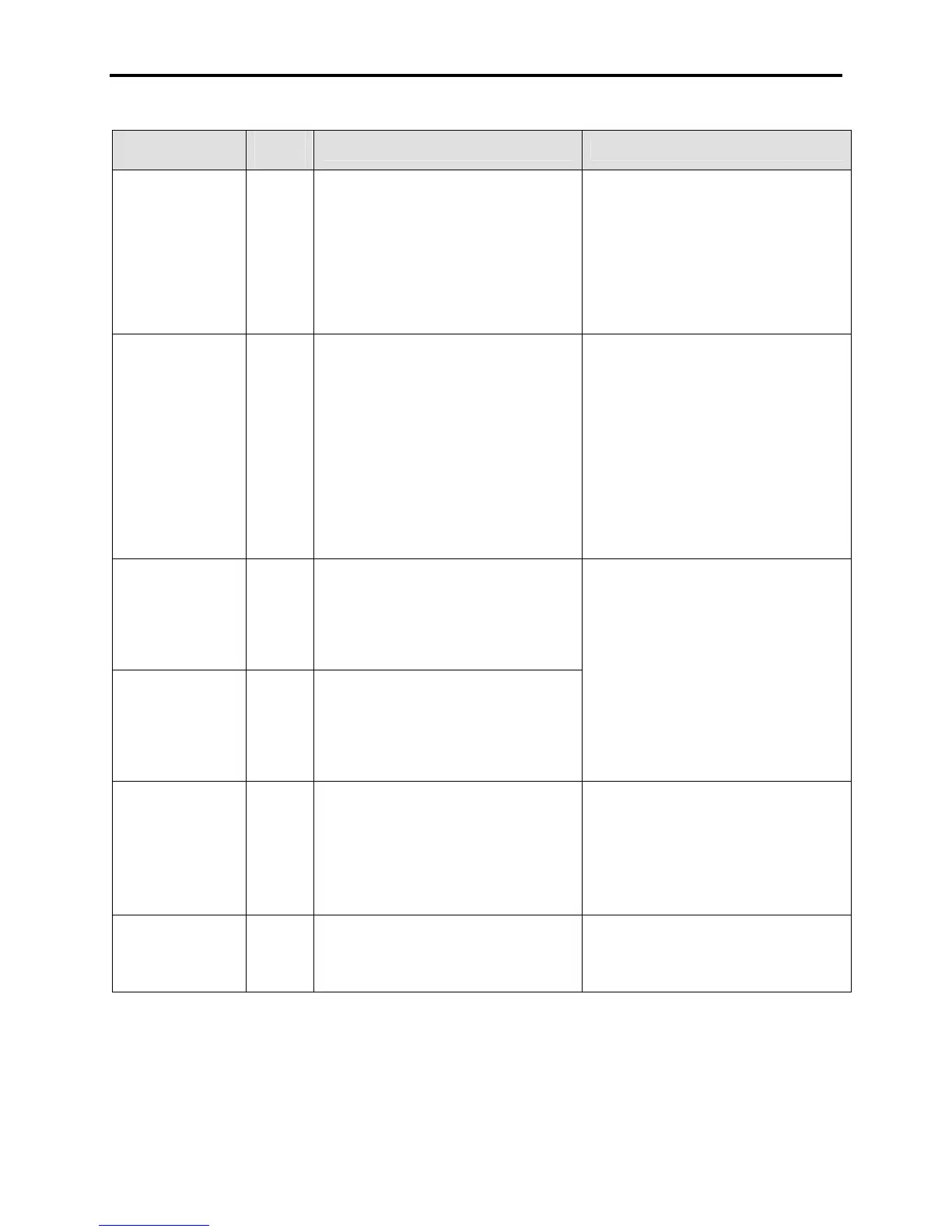

3-4 Troubleshooting

7000-TD002A-EN-P – September 2007

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION RECOMMENDED ACTIONS

Auxiliary Prot’n 37 Standard External Fault/Warning Input

included to allow the end-user to install a

protective relay/system status contact that

can activate a drive fault or warning,

depending on configuration of Aux Prot

Class (P445). The message means drive

has detected a fault triggered by the input

wired in the auxillary input of the XIO card.

Also check the 120V wiring and the XIO card.

– Check device responsible for the

auxiliary contact to this input, and

investigate cause of the open contact

status

– Check the 120V signal through the

external device

– Check the XIO board inputs and

parameter status bits

Bypass CtctrOpen 168 The bypass contactor was opened without a

command from the drive. Verify the

contactor feedback and the 120V wiring to

the ACB.

– The drive system needs to have

complete control over all contactors, so

investigation of the specific contactor

fault is required

– Verify contactor feedback

– Verify the control power circuit for the

contactor

– Check permissive string to the contactor

control relay (refer to drawing) -Check

contactor/breaker for physical

malfunction (auxiliaries)

– Check ACB inputs and outputs at J1.

Bypass IsoSwClsd 175 The bypass isolation switch is closed when

it was expected to be open. Verify the

isolation switch mechanical set up and the

120V wiring to the ACB. Depending on the

Operating Mode of the drive, ensure that the

switch is in the proper position.

Bypass

IsoSwOpen

172 The bypass isolation switch is open when it

was expected to be closed. Verify the

isolation switch mechanical set up and the

120V wiring to the ACB. Depending on the

Operating Mode of the drive, ensure that the

switch is in the proper position.

– Depending on the mode of operation

(Normal, System Test, Open-Circuit

Test, DC Current Test, or Open-Loop),

there are specific states for all the

possible system isolation switches (Refer

to the description of the Parameter 141 –

Hardware Options1). Ensure the isolation

switches are in the proper position.

– Verify wiring feedback

– Verify isolation switch mechanical

auxiliary setup

– READ ASSOCIATED DESCRIPTION

CabinetTemp High

(C-Frame Only)

70 The drive has a temperature switch in

several cabinets, and all the N/C switches

are connected in series and fed back to the

XIO input. The levels are set differently for

different cabinets.

– Identify which switch has opened, and

focus on that cabinet

– Check for proper air flow within the

identified section

– Verify muffin fans are operating correctly

– Verify ambient temperature is within

tolerances

Control Pwr Loss 57 There has been a loss or dip in the control

power feeding the drive for more than

5cycles.

– Ensure that the power source is active

and investigate the reliability of the

source.

– Check control power input to ACB

Loading...

Loading...