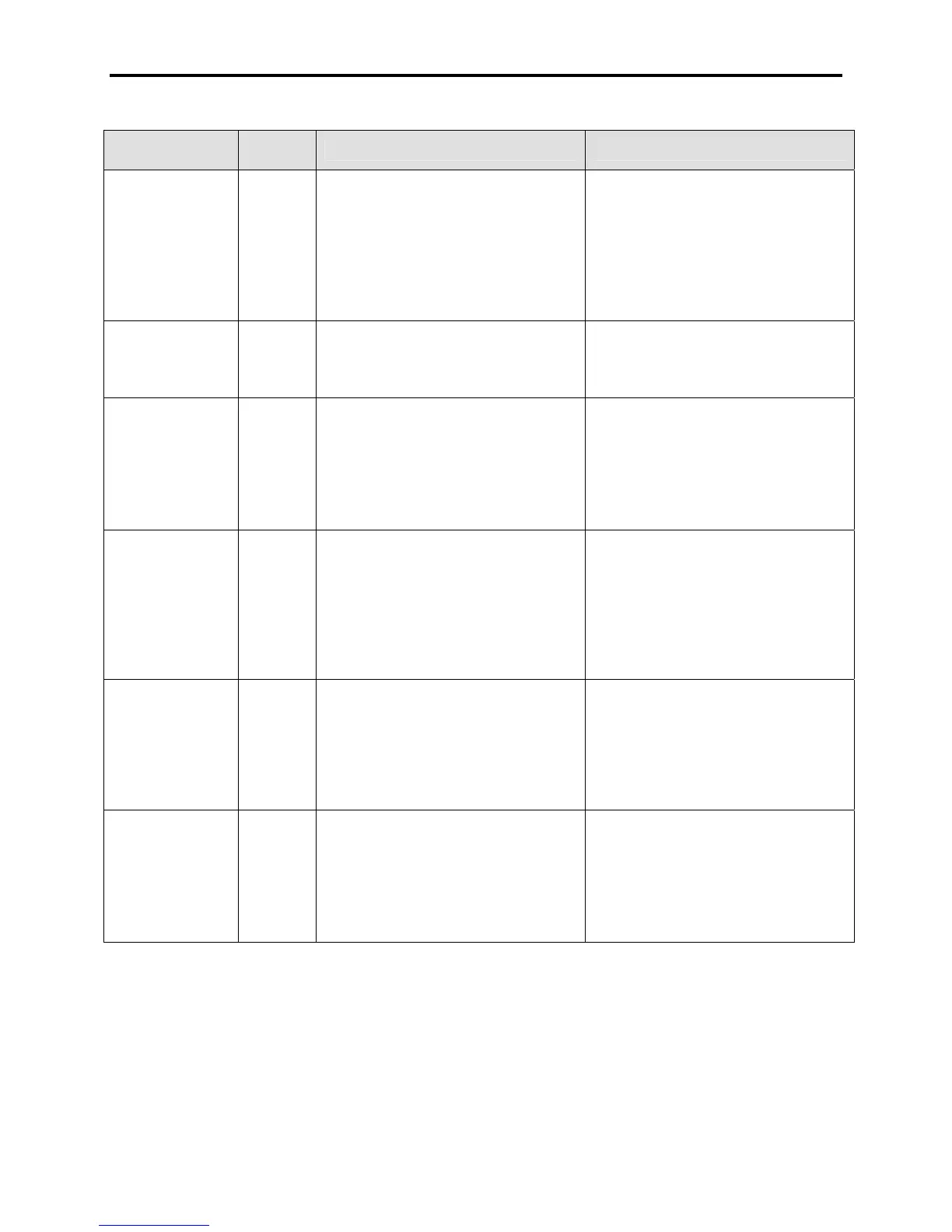

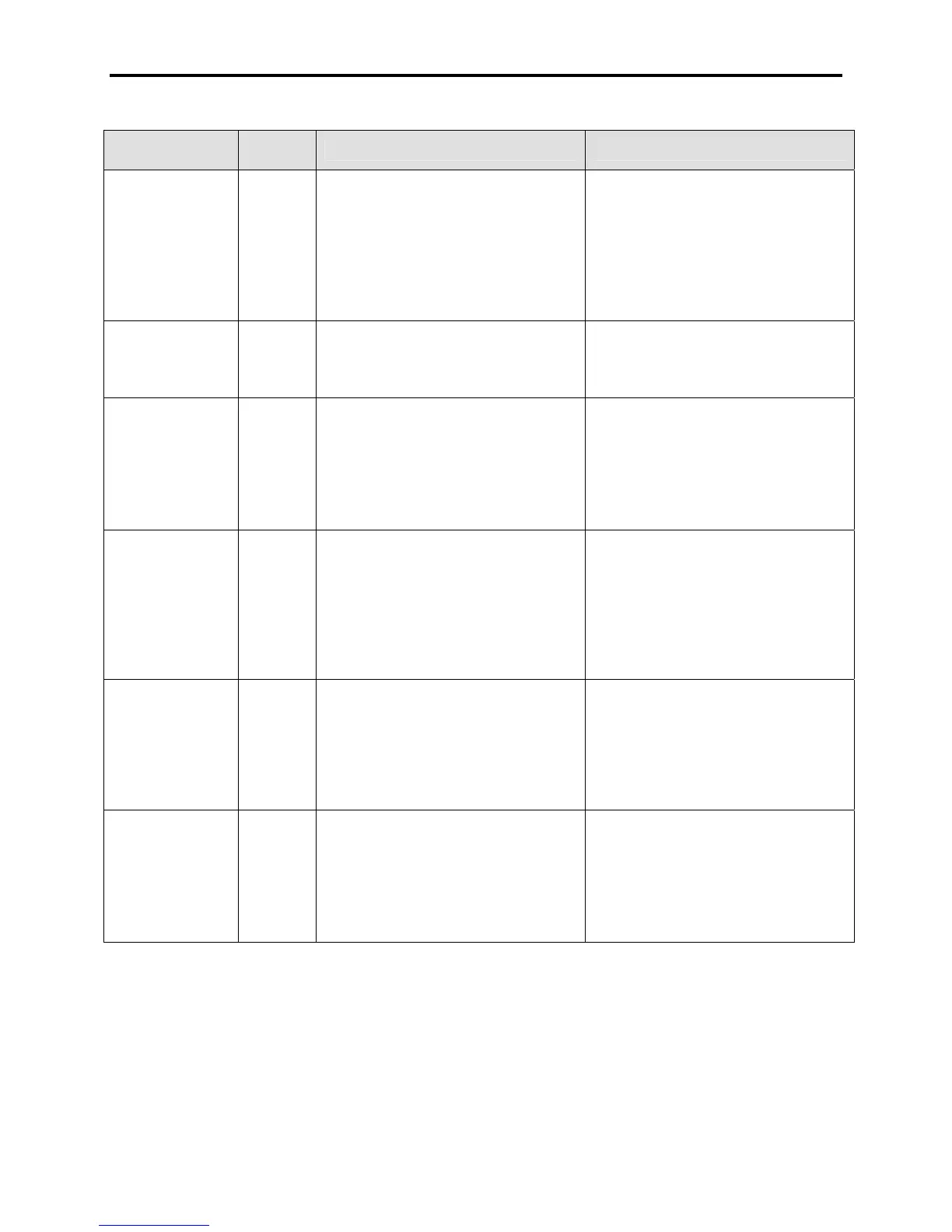

Troubleshooting 3-35

7000-TD002A-EN-P – September 2007

WARNING

MESSAGE

WARNING

CODE

DESCRIPTION RECOMMENDED ACTIONS

Bypass OvrVolt 141 The measured line voltage Bypass Voltage

pu (#P117) has exceeded the Line OvrVolt

Trip (P165) setting. Synchronous transfer

has been disabled.

– Verify the parameters are set properly

– Check for possible line voltage

transients

– Verify VSB connections and tap settings,

resistor values, and grounds

– If voltage is too high, change tap

settings on the input source to lower

voltage to an acceptable level

Bypass Phase Seq 144 The bypass phase sequence does not

match the phase sequence of the input to

the drive. Synchronous transfer has been

disabled.

– The drive will not allow a synchronous

transfer unless the phasing is the same

– Confirm the phase sequences and swap

cables if necessary

Bypass UnderVolt 142 The measured bypass voltage Bypass

Voltage pu (#P117) is less than the Line

UndVolt Lvl (P167) setting. Synchronous

transfer has been disabled.

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm integrity

– Check for possible source voltage

supply problems

– Use Multimeter and Oscilloscope to

check voltages on the drive test points

Bypass VoltUnbal 143 The measured unbalance in the Bypass

Voltage has exceeded the trip setting

(P271). Synchronous transfer has been

disabled.

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm integrity

– Check for possible source voltage

supply problems

– Use Multimeter and Oscilloscope to

check voltages on the drive voltage test

points

ConductivityHigh

(C-FRAME ONLY)

37 This warning is for liquid cool drives. The

drive indicates that the measured coolant

conductivity is greater than 1 μS/cm

3

. Verify

that there is no debris in the coolant, and

replace the de-ionizing cartridge if

necessary

– Verify that no foreign debris has entered

the system (iron piping, non-deionized

water, etc.)

– There is no immediate need for action,

but be prepared to change the de-ionizing

cartridge and run the system, verifying

that the conductivity is decreasing

Control Pwr Loss 112 This is used in the Autorestart feature

algorithm as an indicator to tell the drive to

stop gating and wait for control power to

return. This alarm is for drives engineered

with a UPS option. There has been a loss or

dip in the control power feeding the drive for

more than 5 cycles.

– Investigate reliability of the control power

– Ensure the drive operates as expected

when there is a control power outage

(UPS must be installed)

– Ensure that the power source is active

and investigate the reliability of the

source.

Loading...

Loading...