Examples

4.2 Examples 3-6: SETTCOR function for tool environments

Basic logic functions: Tool Offset (W1)

194 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

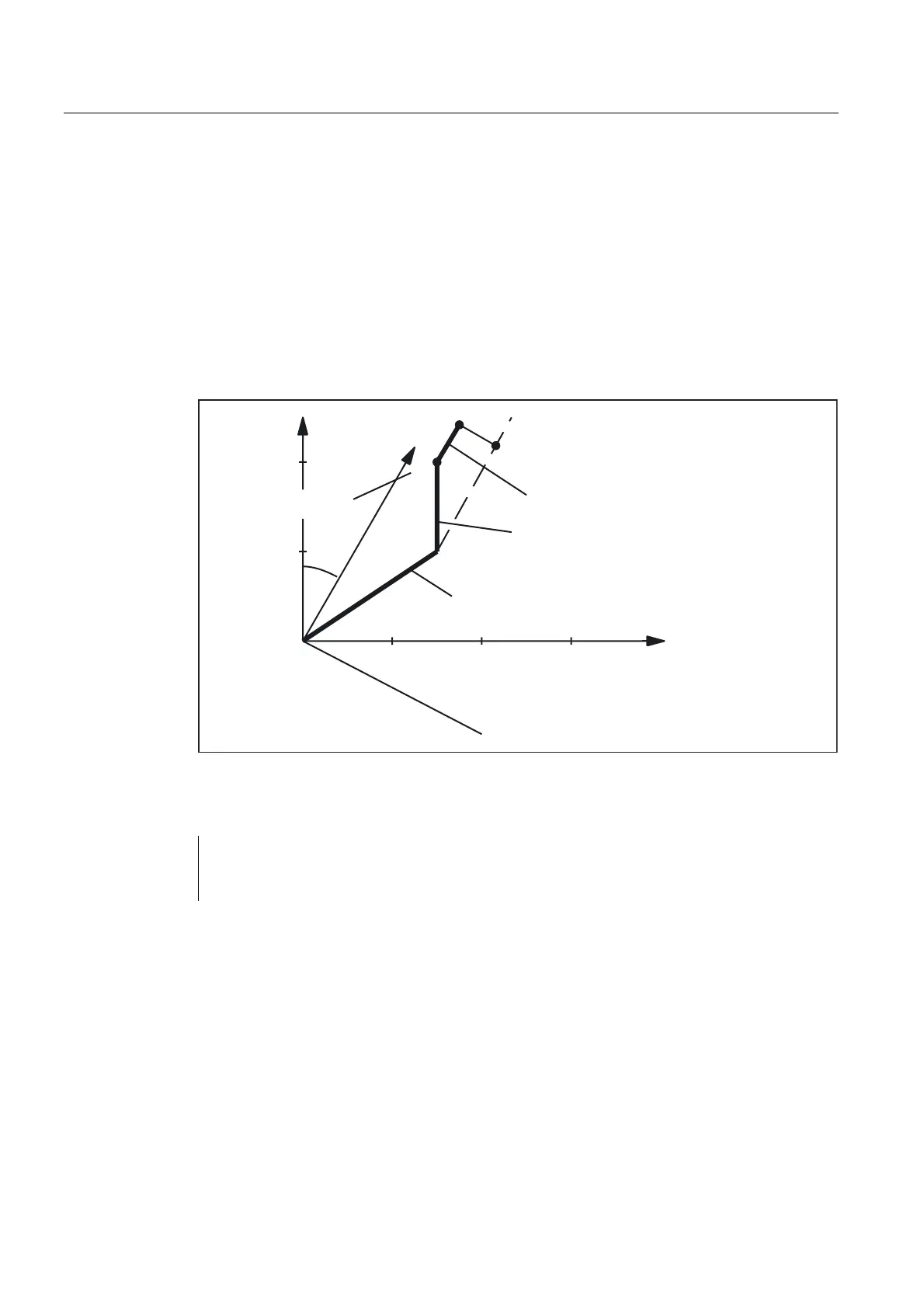

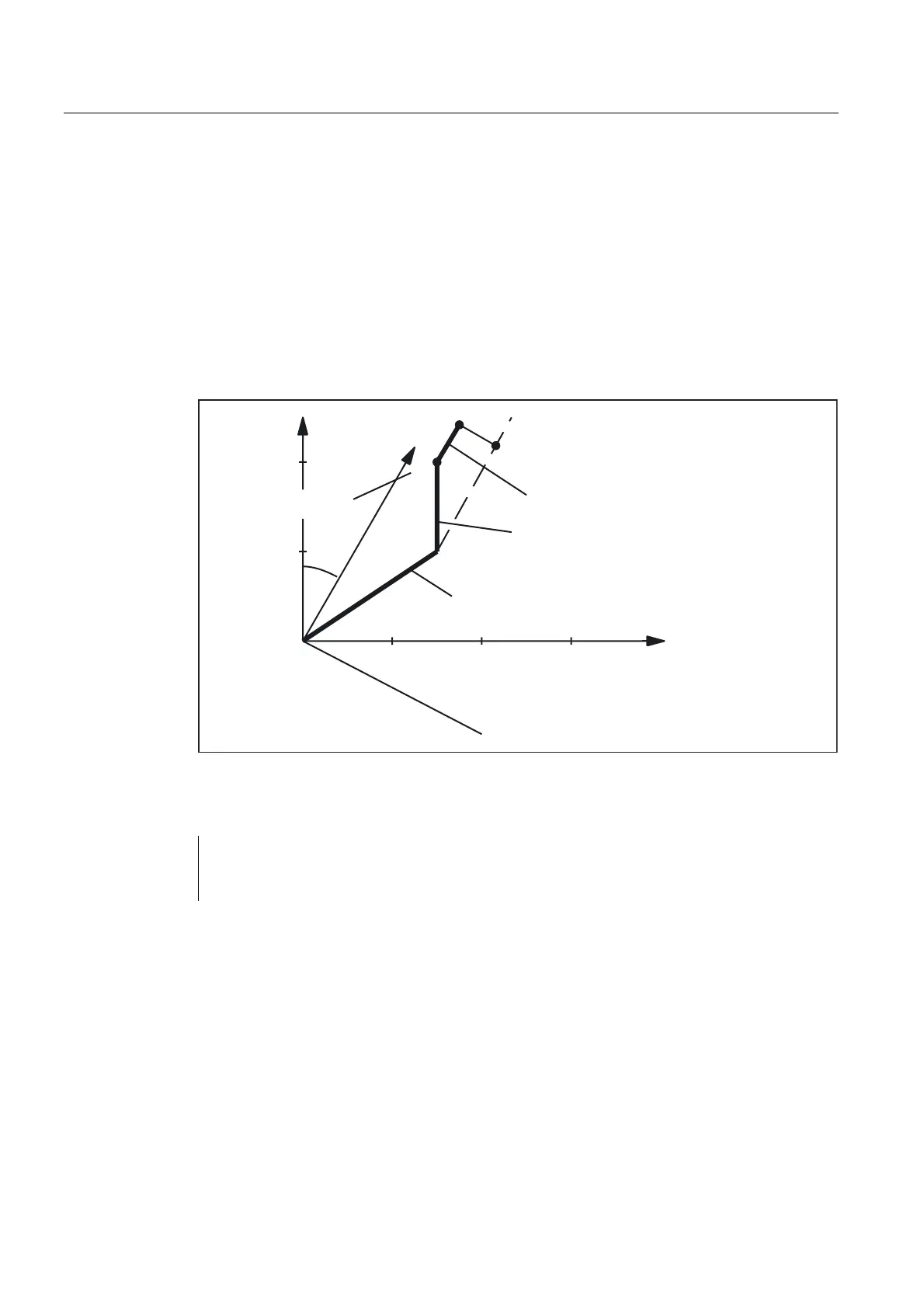

The total wear including _CORVAL is mapped onto the X' direction in the WCS. This

produces point P2. The coordinates of this point (measured in X/Y coordinates) are entered

in the geometry component of the tool. The difference vector P

2

- P

1

remains in the wear.

The wear thus no longer has a component in the direction of _CORVAL.

B&259$/ HIIHFWLYHLQ;GLUHFWLRQ

:HDU/ /

*HRPHWU\/ /

2ULJLQDO

WRROOHQJWK

;

=

;

=

3

3

3

Figure 4-1 Tool length compensation, example 6

If the sample program is continued after N110 with the following instructions:

N120

_CORVAL[0] = 0.0

N130

r1 = settcor(_CORVAL, "GW", 0, 3, 0)

N140

t1 d1 x0 y0 z0 ; ==> MCS position X24.330 Y0.000 Z17.500

The remaining wear is included completely in the geometry because the compensation is

now effective in the Z' axis (parameter _GEOAX is 0). Since the new compensation value is

0, the total tool length and thus the position approached in N140 may not change. If

_CORVAL were not equal to 0 in N120, a new total tool length and thus a new position in

N140 would result, however, the wear component of the tool length would always be zero,

i.e., the total tool length is subsequently always contained in the geometry component of the

tool.

Loading...

Loading...