Detailed description

2.10 System settings for power-up, RESET/part-program end and part-program start

Basic logic functions: Mode group, channel, program operation, reset response (K1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

171

Application

If a bit is set in MD20112 $MC_START_MODE_MASK, the reset action of the relevant

function can be delayed until the start of the part program.

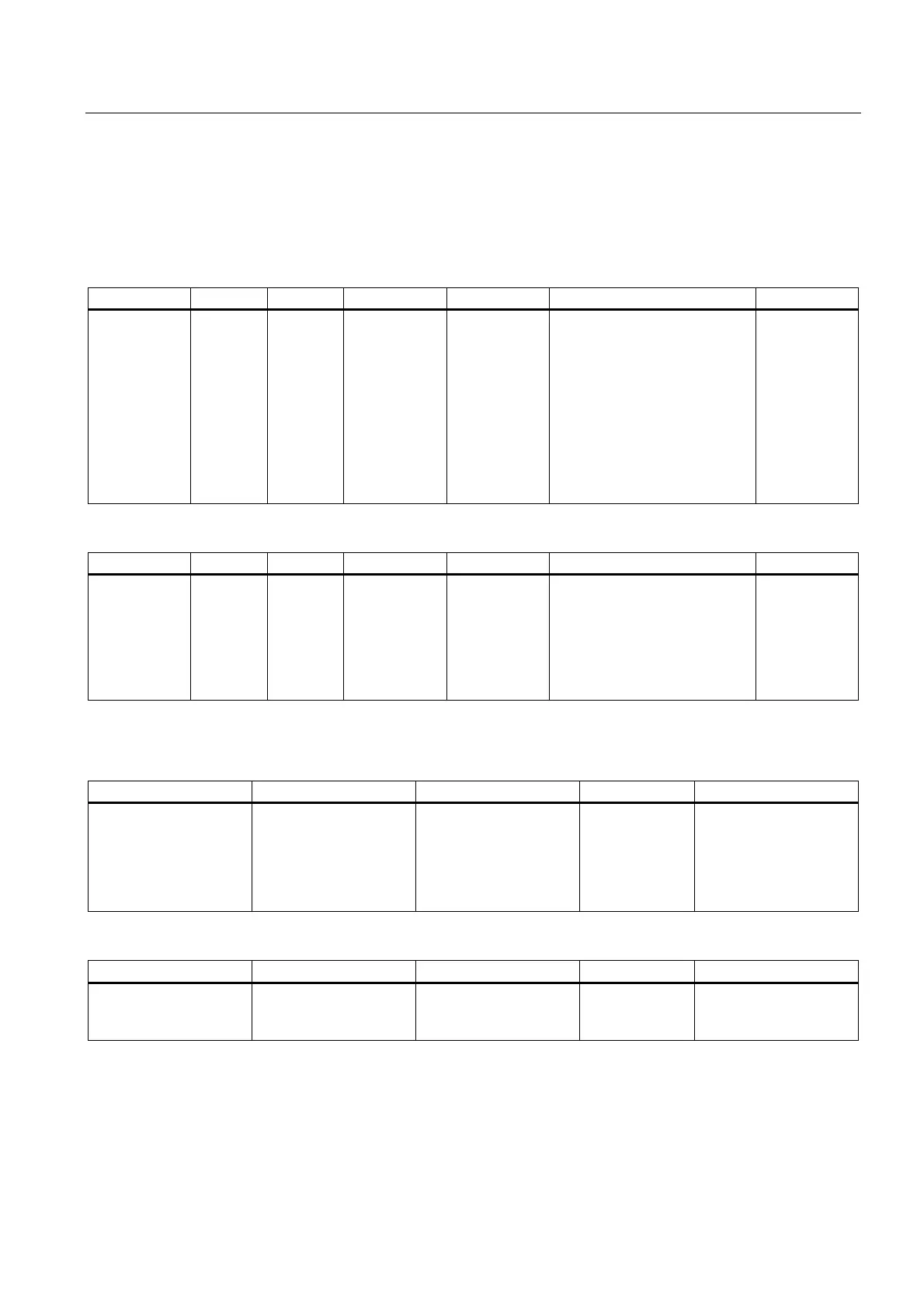

Table 2-17 Effect of MD20112 $MC_START_MODE_MASK Bits 1 to 7

Bit 1 = 1 Bit 2 = 1 Bit 3 = 1 Bit 4 = 1 Bit 5 = 1 Bit 6 = 1 Bit 7 = 1

No D, T, M

output on tool

selection;

with active

tool

management

irrelevant

Reserved Reserved Plane

according to

MD20150

$MC_GCODE

_RESET_VAL

UES

Frame

according to

MD20150

$MC_GCODE

_RESET_VAL

UES

WZK according to

MD20120

$MC_TOOL_RESET_VALUE,

MD20121

$MC_TOOL_PRESEL_RESET

_

VALUE, and

MD20130 $MC_CUTTING_

EDGE_RESET_VALUE;

Output of D, T, M to PLC,

depending on bit 1

Transformatio

n according to

MD20140

$MC_TRAFO_

RESET_VALU

E

Bit 1 = 0 Bit 2 = 0 Bit 3 = 0 Bit 4 = 0 Bit 5 = 0 Bit 6 = 0 Bit 7 = 0

D, T, M output

on tool

selection;

with active

tool

management

irrelevant

Reserved Reserved Current plane

is retained

Current

settable frame

is retained

Active tool length offset is

retained

Active

transformation

is retained

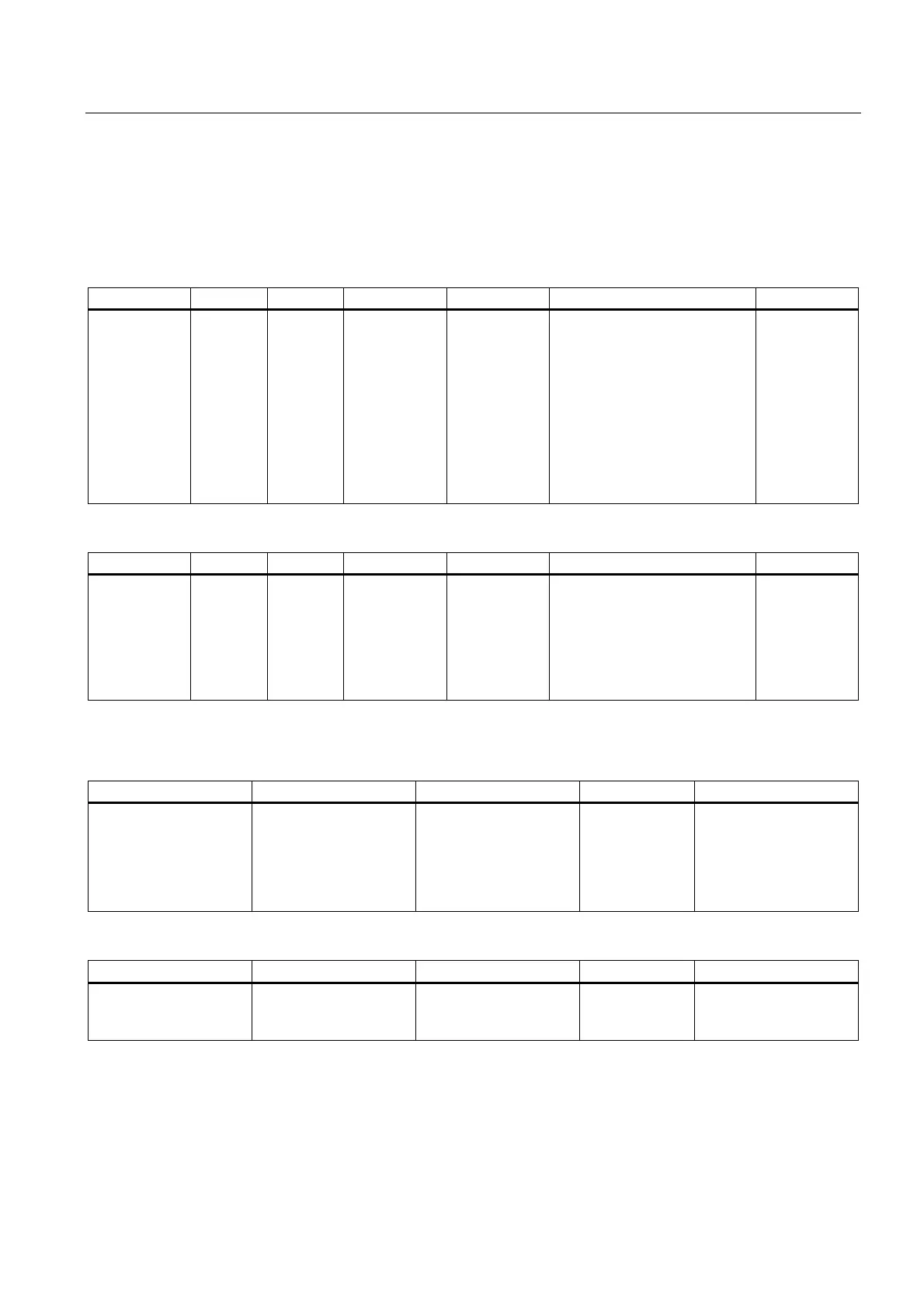

Table 2-18 Effect of MD20112 $MC_START_MODE_MASK Bits 8 to 12

Bit 8 = 1 Bit 9 = 1 Bit 10 = 1 Bit 11 = 1 Bit 12 = 1

Coupledaxis groupings

are deactivated

Tangential follow-up is

deactivated

Not configured

synchronous spindle

coupling is switched off

Reserved Geometry axis

assignment is deleted

according to MD 20050,

depending on MD

20118 (because of

compatibility)

Bit 8 = 0 Bit 9 = 0 Bit 10 = 0 Bit 11 = 0 Bit 12 = 0

Coupledaxis groupings

are retained

Tangential follow-up is

retained

Not configured

synchronous spindle

coupling remains active

Reserved Modified geometry axis

assignment is retained

Loading...

Loading...