InspectingtheGearPump(continued)

CAUTION

Useeyeprotectionsuchasgoggleswhenusingcompressedair.

2.Cleanallpartswithsolvent.Dryallpartswithcompressedair.

3.Inspectthedrivegearanddrivengearforthefollowing:

A.Thegearshaftsshouldbefreeofroughsurfacesandexcessivewearat

thethrustplatepointsandsealingareas.

B.Thegearteethshouldbefreeofexcessivescoringandwear.

C.Inspecteachgearfaceedgeforsharpedgesorburrs.Removesharp

edgesorburrsfromthegearfaceswithemerycloth.

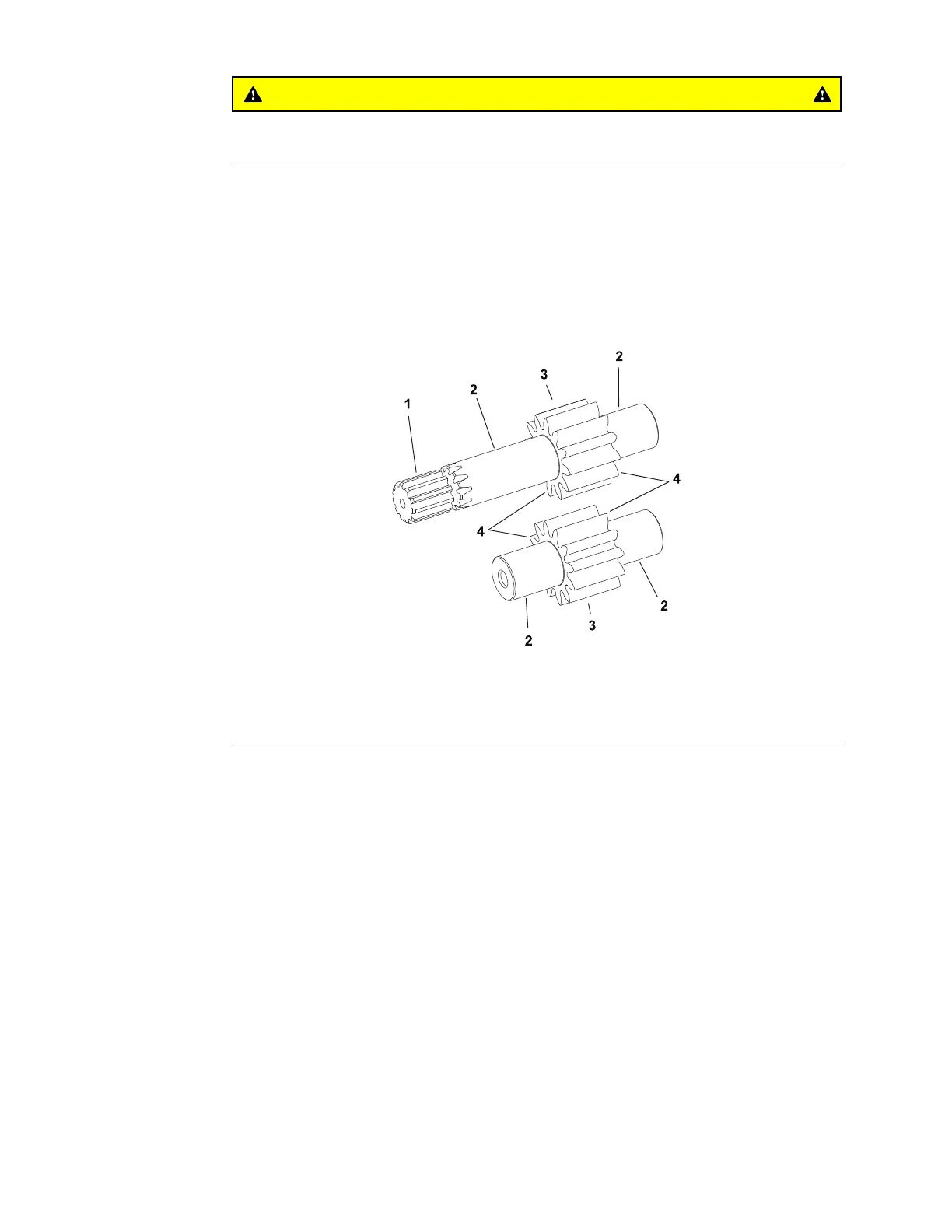

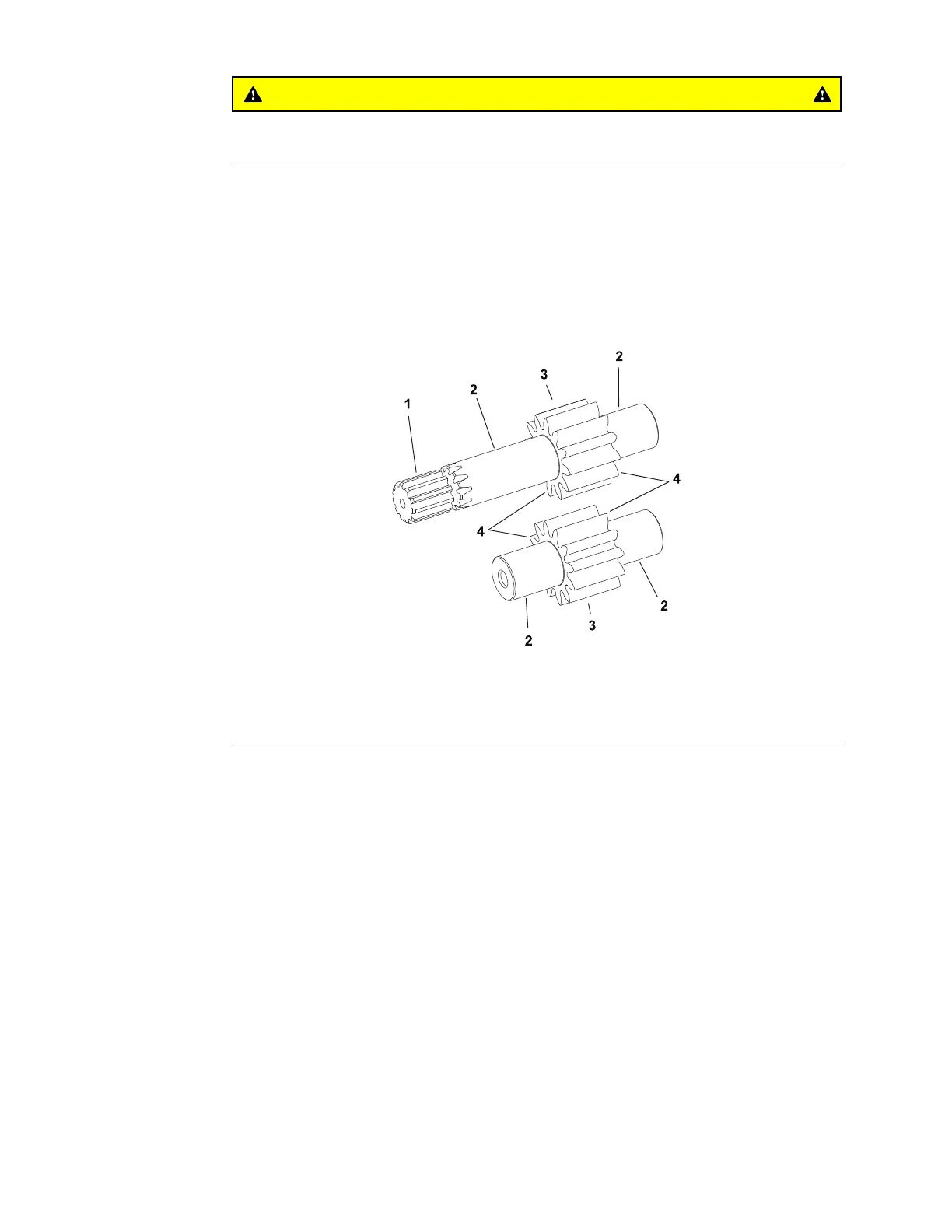

g240513

Figure57

1.Gearshaftspline3.Gearteeth

2.Gearshaft4.Gearfaceedge

4.Inspectthethrustplatesforthefollowing:

A.Thebearingareasshouldnothaveexcessivewearorscoring.

B.Thefaceofthethrustplatesthatareincontactwiththegearsshouldbe

freeofwear,roughnessorscoring.

C.Thethicknessofthethrustplatesshouldbeequal.

5.Inspectthefrontcoverandtherearcoverfordamageorwear.

AssemblingtheGearPump

RefertoFigure55forthisprocedure.

Whenassemblingthepump,checkthemarkerlineoneachparttomakesure

thepartsareproperlyalignedduringassembly.Whenassemblingthepump,

checkthemarkerlineoneachparttomakesurethepartsareproperlyaligned

duringassembly.

1.Lubricatethebodyseals,pressureseals,uni-ringsandthethrustplate

grooveswithathincoatofpetroleumjelly.Lubricateallotherinternalparts

freelywithcleanhydraulicoil.

2.Installnewseals,thebackupwasher,andtheretainingringinthefrontcover.

HydraulicSystem:ServiceandRepairs

Page5–80

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...