www.dadehpardazan.ir 88594014-15

5.2 Basic Functions Settings

5-7

5.2.4 Overtravel

The overtravel limit function forces movable machine parts to stop if they exceed the allowable range of

motion and turn ON a limit switch.

(1) Signal Setting

Movement in the opposite direction is possible during overtravel by inputting the reference.

CAUTION

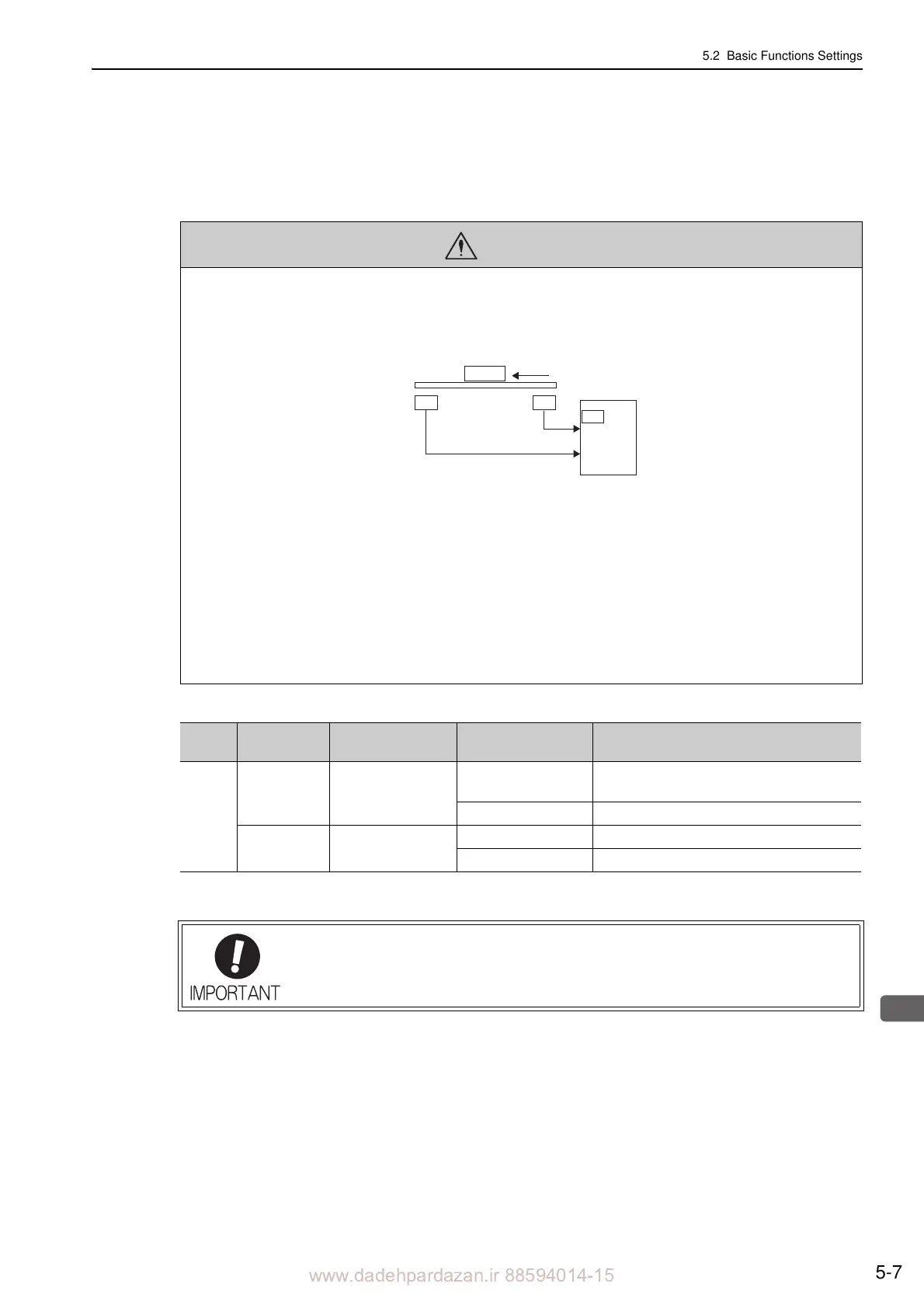

• Installing limit switches

For machines that move using linear motion, connect

limit switches to P-OT and N-OT of CN1 as shown below to

prevent machine damage. To prevent a contact fault or disconnection from causing accidents, make sure that the limit

switches are normally closed.

• Axes to which external force is applied in overtravel

Vertical axes:

Occurrence of overtravel may cause a workpiece to fall, because the /BK signal is on, that is when the brake is

r

eleased. Set the parameter (Pn001 = n.1) to bring the servomotor to zero clamp state after stopping to prevent

a workpiece from falling.

Other axes to which external force is applied:

Overtravel will bring about a baseblock state after

the servomotor stops, which may cause the servomotor to be

pushed back by the load’s external force. To prevent this, set the parameter (Pn001 = n.1) to bring the servo-

motor to zero clamp state after stopping.

For details on how to set the parameter, refer to (3) Servomotor Stopping Method When

Overtravel is Used.

43

CN1

42

P-OT

N-OT

Limit

switch

Servomotor

SERVOPACK

Limit

switch

Forward direction

Type Name

Connector

Pin Number

Setting Meaning

Input

P-OT CN1-42

ON

Forward run allowed.

Normal operation status.

OFF Forward run prohibited. Forward overtravel.

N-OT CN1-43

ON Reverse run allowed. Normal operation

status.

OFF Reverse run prohibited. Reverse overtravel.

When the servomotor stops due to overtravel during position control, the position errors

are held. A clear signal (CLR) input is required to clear the error pulses.

For the clear signal, refer to 5.4.2 Clear Signal Setting.

Loading...

Loading...