www.dadehpardazan.ir 88594014-15

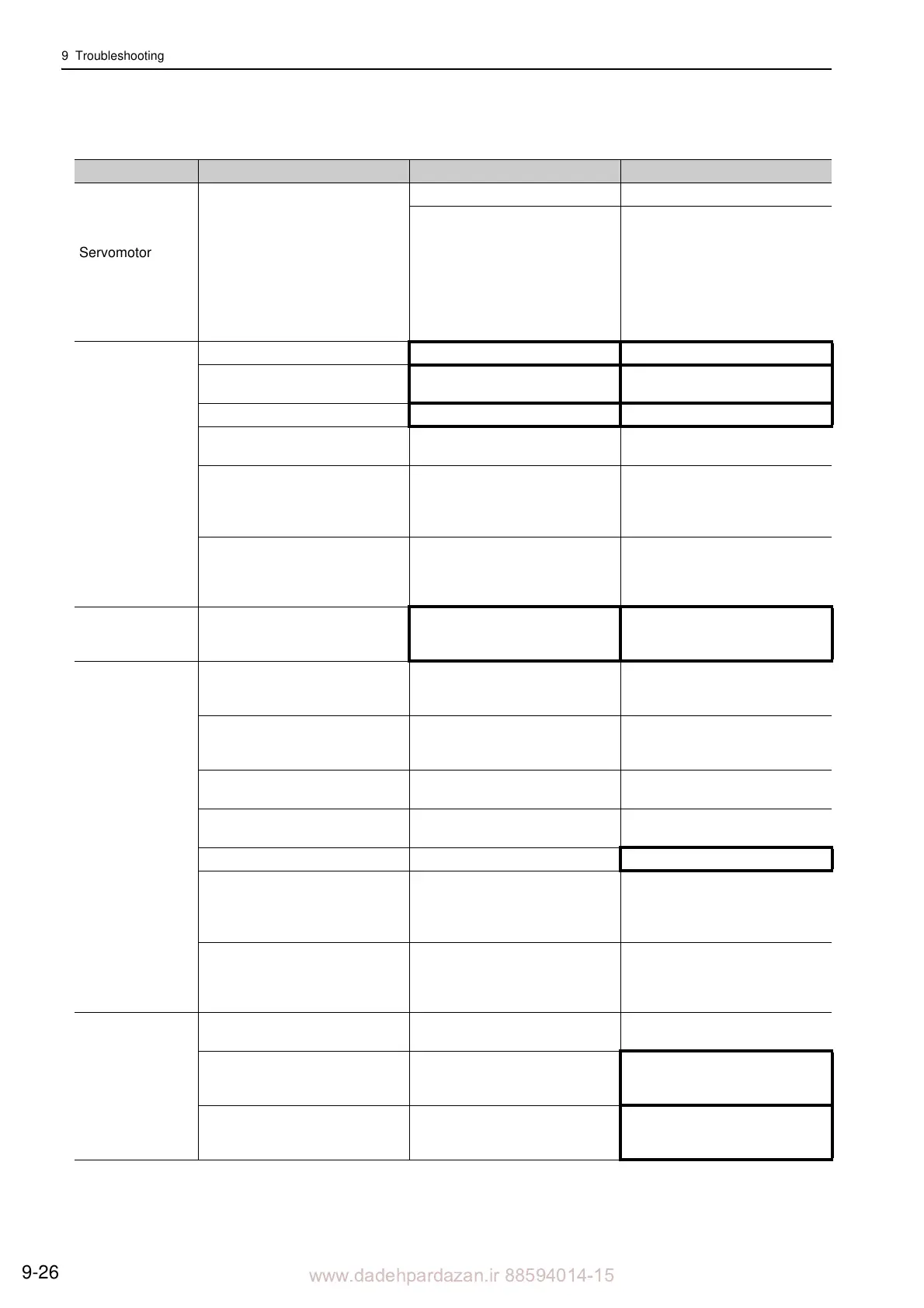

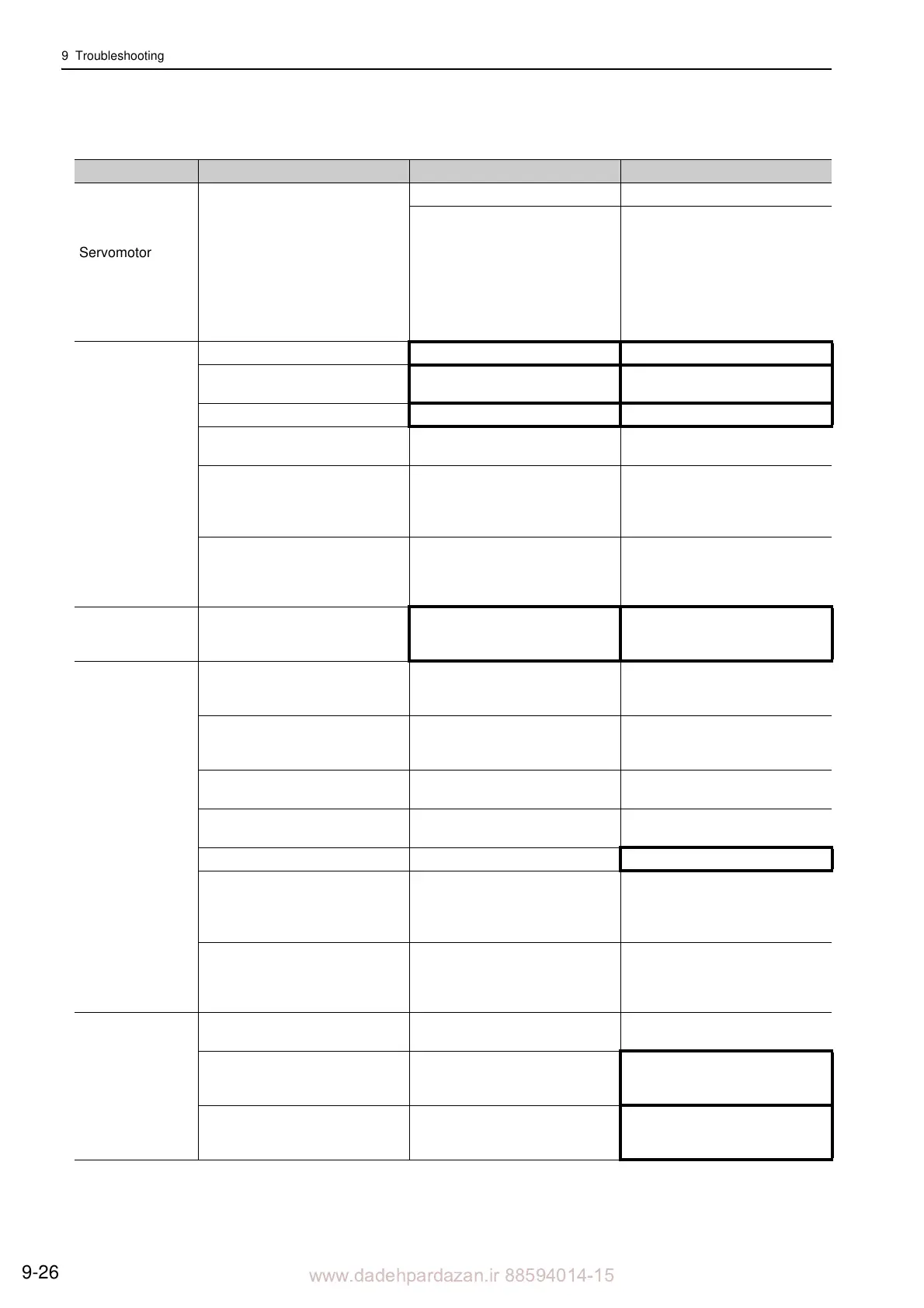

9 Troubleshooting

9-26

Servomotor Does

Not Start (cont’d)

The polarity detection is not exe-

cuted.

Check the parameter Pn080.0. Correct the setting of Pn080.0.

Check the /S-ON or /P-DET input

signal.

• When using an incremental linear

sc

ale, turn ON the /S-ON or /P-

DET input signal.

• When using an absolute linear

s

cale, turn OFF the external /S-

ON input signal and execute

Fn080.

Servomotor

Moves

Instanta-

neously,

and then

Stops

Servomotor wiring is incorrect. Check the wiring. Correct the wiring.

Serial converter unit wiring is incor-

rect.

Check the wiring. Correct the wiring.

Linear scale wiring is incorrect. Check the wiring.

Correct the wiring.

Linear scale pitch (Pn282) is incor-

rect.

Check the setting of Pn282. Correct the setting of Pn282.

Linear scale counting up direction

and servomotor coil assembly for-

ward direction do not agree.

Check the directions.

Change the setting of Pn080.1

(Motor Phase Selection).

Match the linear scale direction and

coil assembly direction.

Polarity detection is not performed

correctly.

Check if the value of Un004 (elec-

trical angle 2 from polarity origin)

at an ar

bitrary position is between

10 degrees.

Correct the settings for the polarity

detection related parameter.

Servomotor

S

peed Unstable

Wiring connection to servomotor is

defective.

Check connections of power

line

(phases U, V, and W) and serial

converter unit connectors.

Tighten any loose terminals or con-

nectors and correct the wiring.

Servomotor

Moves W

ithout

Reference Input

Speed control: Speed reference

input is

incorrect.

Check V-REF and SG to confirm if

the control method an

d the input are

agreed.

Correct the control method selec-

tion parameter, and the input signal.

Force control: Force refer

ence input

is incorrect.

Check V-REF and SG to confirm if

the control method and the input are

agreed.

Correct the control method selec-

tion parameter, and the input signal.

Speed reference offset is incorrect.

The SERVOPACK offset is

adj

usted incorrectly.

Adjust the SERVOPACK offset.

Position control: Reference p

ulse

input is incorrect.

Check the reference pulse form

(Pn200.0) and sign + pulse signal.

Correct the control method selec-

tion parameter, and the input signal.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Linear scale counting up direction

and servomo

tor coil assembly for-

ward direction do not agree.

Check the directions.

Change the setting of Pn080.1

(Motor Ph

ase Selection).

Match the linear scale d

irection and

servomotor direction.

Polarity detection is not performed

corre

ctly.

Check if the value of Un004 (elec-

trical angle 2 from polarity origin)

at an arbitrary position is between

10 degrees.

Correct the settings for the polarity

detection related par

ameter.

Dynamic Brake

Doe

s Not Operate

Improper Pn001.0 setting

Check the setting for parameter

Pn001.0.

Correct the setting for parameter

Pn00

1.0.

DB resistor disconnected

Check if excessive mass, motor

ov

erspeed, or DB frequently acti-

vated occurred.

Replace the SERVOPACK, and

reduc

e the load.

DB drive circuit fault

There is a defective component in

the

DB circuit. Replace the SER-

VOPACK.

(cont’d)

Problem Probable Cause Investigative Actions Corrective Actions

Loading...

Loading...