3.6 Main Circuit Wiring

YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07) 69

Electrical Installation

3

◆ Wire Gauges and Tightening Torque

Select the appropriate wires and crimp terminals from Table 3.2 through Ta ble 3.5.

• Consider the amount of voltage drop when selecting wire gauges.

Increase the wire gauge when the voltage drop is greater than 2% of motor rated

voltage. Ensure the wire gauge is suitable for the terminal block. Use the

following formula to calculate the amount of voltage drop:

• Line drop voltage (V) =

• 3 x wire resistance (Ω/km) x wire length (m) x current (A) x 10

-3

Refer to instruction manual TOBPC72060000 for braking unit or braking

resistor unit wire gauges.

• Refer to Standards Compliance on page 435 for information on UL compliance.

Note: 1. Wire gauge recommendations based on drive continuous current ratings using 75°C 600

Vac vinyl-sheathed wire assuming ambient temperature within 30°C and wiring distance

less than 100 m.

2. Terminals +1, +2, –, B1 and B2 are for connecting optional devices such as a DC reactor or

braking resistor. Do not connect other non-specified devices to these terminals.

■

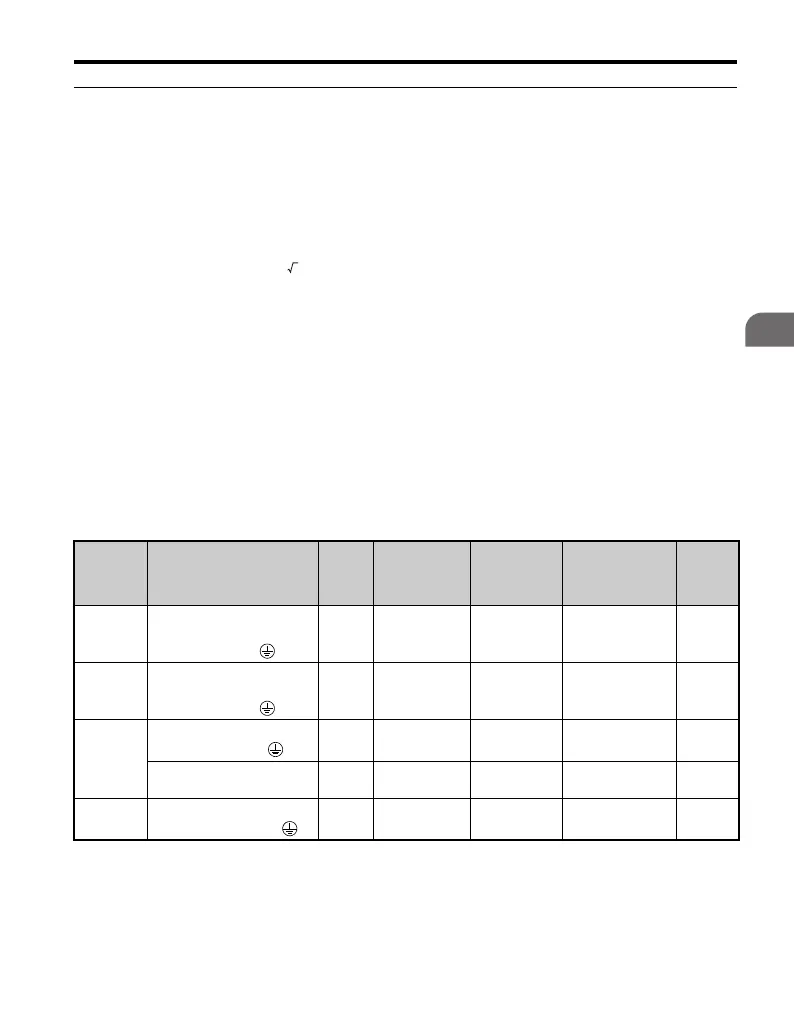

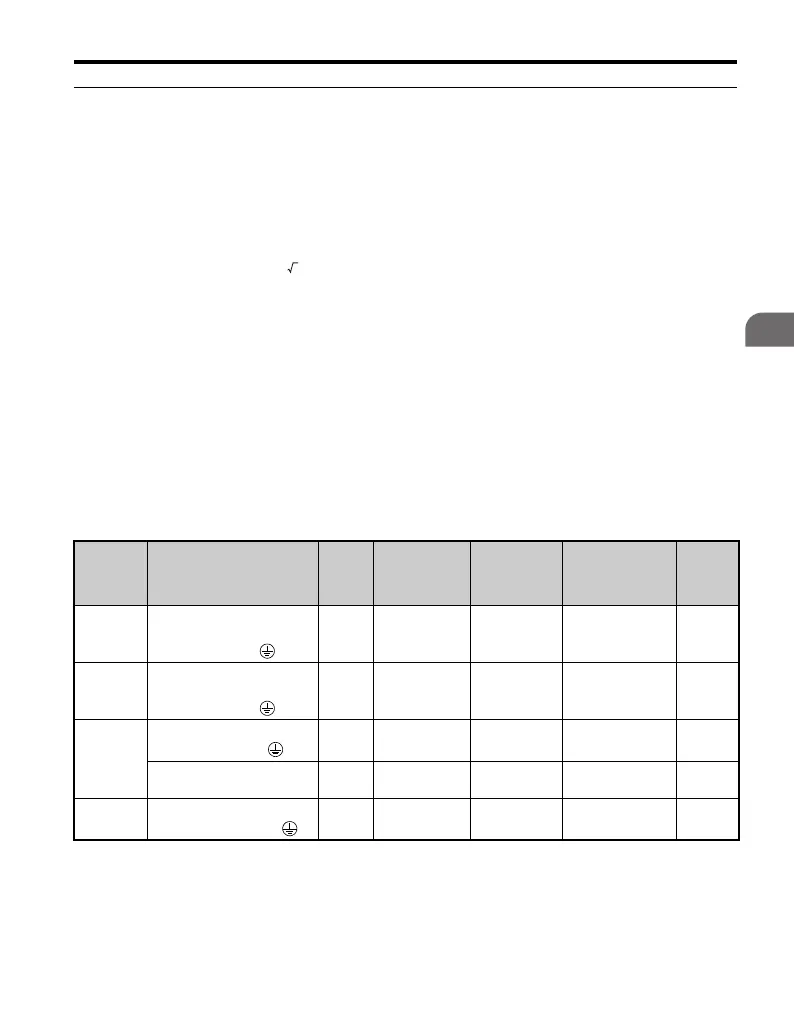

Single-Phase 200 V Class

Table 3.2 Wire Gauge and Torque Specifications

Model

CIMR-

VBA

Terminal

Screw

Size

Tightening

Torque

N•m

(lb.in.)

Applicable

Gauge

mm

2

(AWG)

Recommended

Gauge

mm

2

(AWG)

Line

Type

0001

0002

0003

R/L1, S/L2,

U/T1, V/T2, W/T3,

–, +1, +2, B1, B2,

M3.5

0.8 to 1.0

(7.1 to 8.9)

0.75 to 2.00

(18 to 14)

2.5

(14)

Note: 1.

0006

R/L1, S/L2,

U/T1, V/T2, W/T3,

–, +1, +2, B1, B2,

M4

1.2 to 1.5

(10.6 to 13.3)

2.0 to 5.5

(14 to 10)

2.5

(14)

Note: 1.

0010

R/L1, S/L2,

U/T1, V/T2, W/T3,

M4

1.2 to 1.5

(10.6 to 13.3)

2.0 to 5.5

(14 to 10)

4

(12)

Note: 1.

–, +1, +2, B1, B2, M4

1.2 to 1.5

(10.6 to 13.3)

2.0 to 5.5

(14 to 10)

6

(10)

Note: 1.

0012

R/L1, S/L2, U/T1, V/T2, W/

T3, –, +1, +2, B1, B2,

M4

1.2 to 1.5

(10.6 to 13.3)

2.0 to 5.5

(14 to 10)

6

(10)

Note: 1.

Loading...

Loading...