3.7 Control Circuit Wiring

80 YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07)

◆ Wire Size and Torque Specifications

Select the appropriate wires and crimp terminals from Tab le 3.9.

■ Wire Size and Torque Specifications

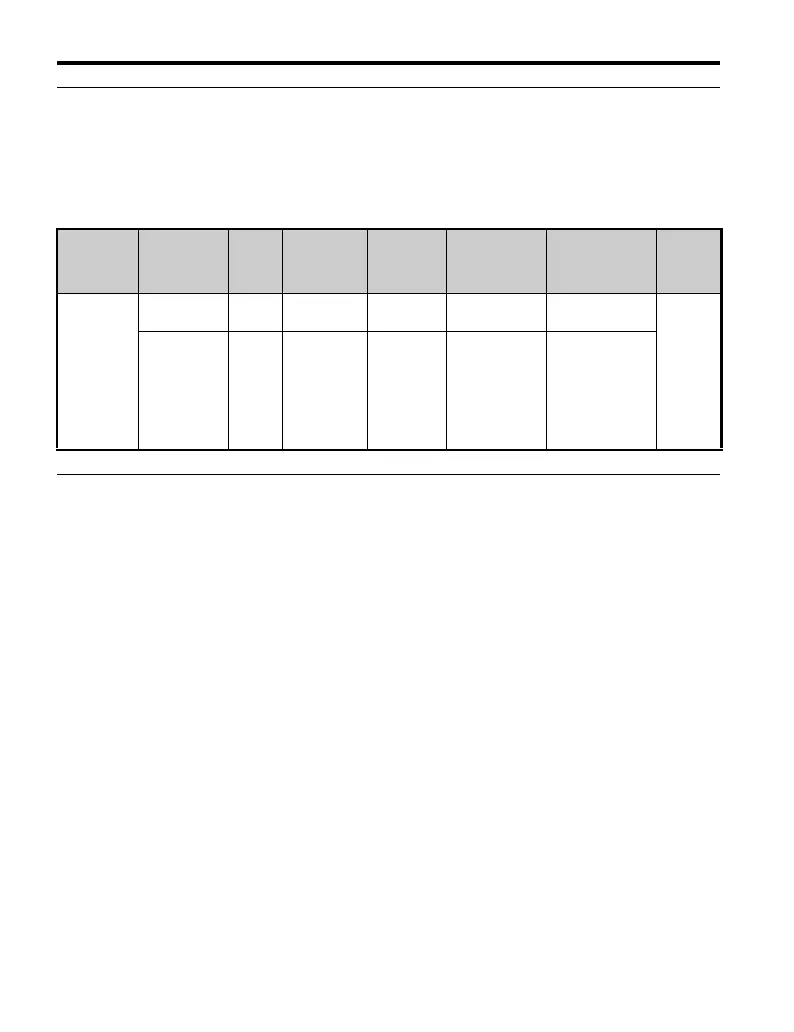

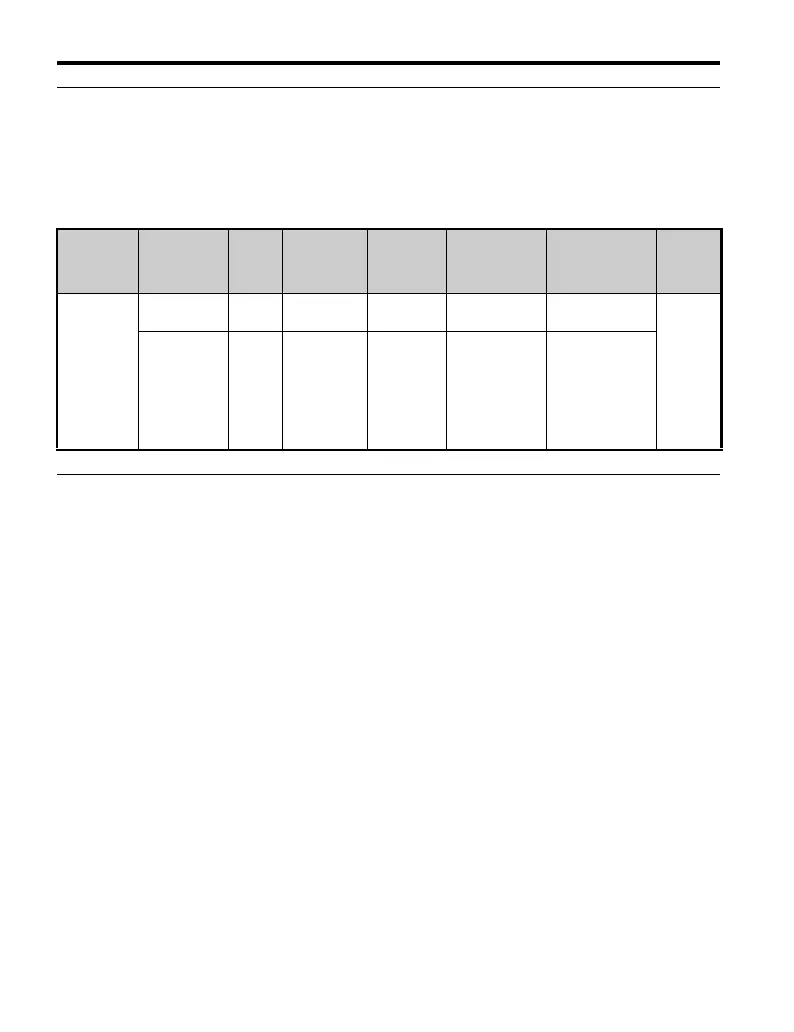

Table 3.9 Wire Size and Torque Specifications (Same for All Models)

◆ Wiring Procedure

This section describes the proper procedures and preparations for wiring the

terminal board.

WARNING! Electrical Shock Hazard. Do not remove covers or touch the circuit boards while

the power is on. Failure to comply could result in death or serious injury.

NOTICE: Separate control circuit wiring from main circuit wiring (terminals R/L1, S/L2, T/L3,

B1, B2, U/T1, V/T2, W/T3, 1, 2 and 3) and other high-power lines. Improper wiring practices

could result in drive malfunction due to electrical interference.

NOTICE: Separate wiring for digital output terminals MA, MB and MC from wiring to other

control circuit lines. Improper wiring practices could result in drive or equipment malfunction or

nuisance trips.

NOTICE: Use a class 2 power supply (UL standard) when connecting to the control terminals.

Improper application of peripheral devices could result in drive performance degradation due

to improper power supply.

NOTICE: Insulate shields with tape or shrink tubing to prevent contact with other signal lines

and equipment. Improper wiring practices could result in drive or equipment malfunction due to

short circuit.

Attachment Terminal

Screw

Size

Tightening

Torque

Nxm

Tightening

Torque

(in-lbs)

Applicable

wire size

mm

2

(AWG)

Recommended

mm

2

(AWG)

Wire

Type

Screw Type

(standard)

MA, MB, MC M3 0.5 to 0.6 4.4 to 5.3

0.25 to 1.25

(24 to 16)

0.75 (18)

Shielded

line, etc.

S+, S-, R+,

R-, IG, SC,

S1-S7, P1,

P2, PC, MP,

RP, AM, +V,

A1, A2, AC,

HC, H1

M2 0.22 to 0.25 1.9 to 2.2

Stranded wire:

0.25 to 0.75

(24 to 18)

Single wire:

0.25 to 1.25

(24 to 16)

0.75 (18)

Loading...

Loading...