156 Rockwell Automation Publication 193-UM015E-EN-P - October 2015

Chapter 5 Operating Modes

Rules

1. For Control Module firmware v1.000 and v2.000, one output relay must

be assigned as a trip relay. Set any of the Output Ptxx Assignments

(Parameters 202…204) to Trip Relay.

2. For Control Module firmware v3.000 and higher, one output relay must be

assig

ned as a trip relay or control relay. Set any of the Output Ptxx

Assignments (Parameters 202…204) to Trip Relay or Control Relay.

3. Overload Trip must be enabled in TripEnableI (Parameter 183).

Wiring Diagram

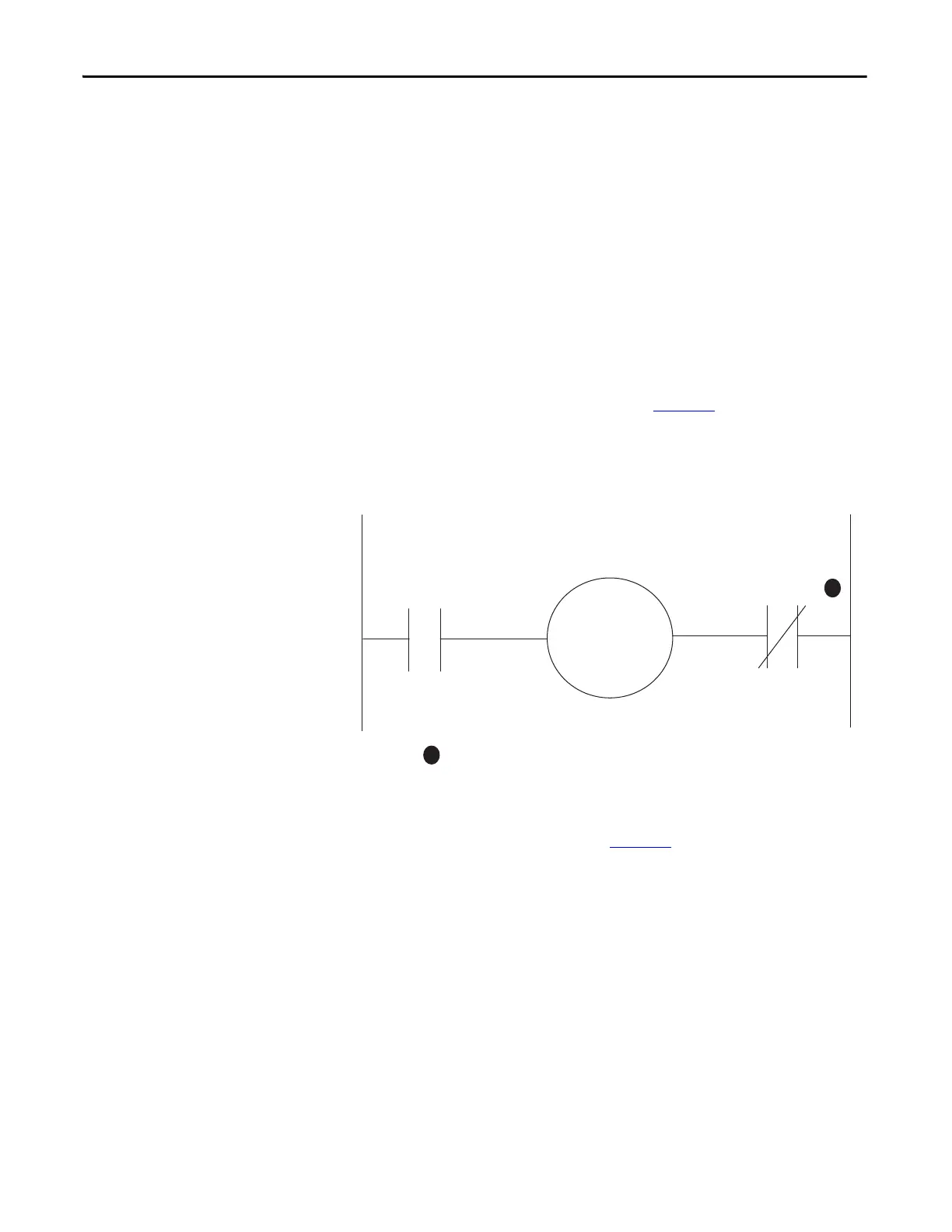

The E300 relay is wired as a traditional overload relay with one of the output

relays configured as a normally closed trip relay. Figure 55

is a wiring diagram of a

non-reversing starter. Relay 0 is configured as a trip relay, and Relay 1 is

configured as a normally open control relay, which receives commands from an

automation controller to energize the contactor coil.

Figure 55 - Trip Relay Wiring Diagram

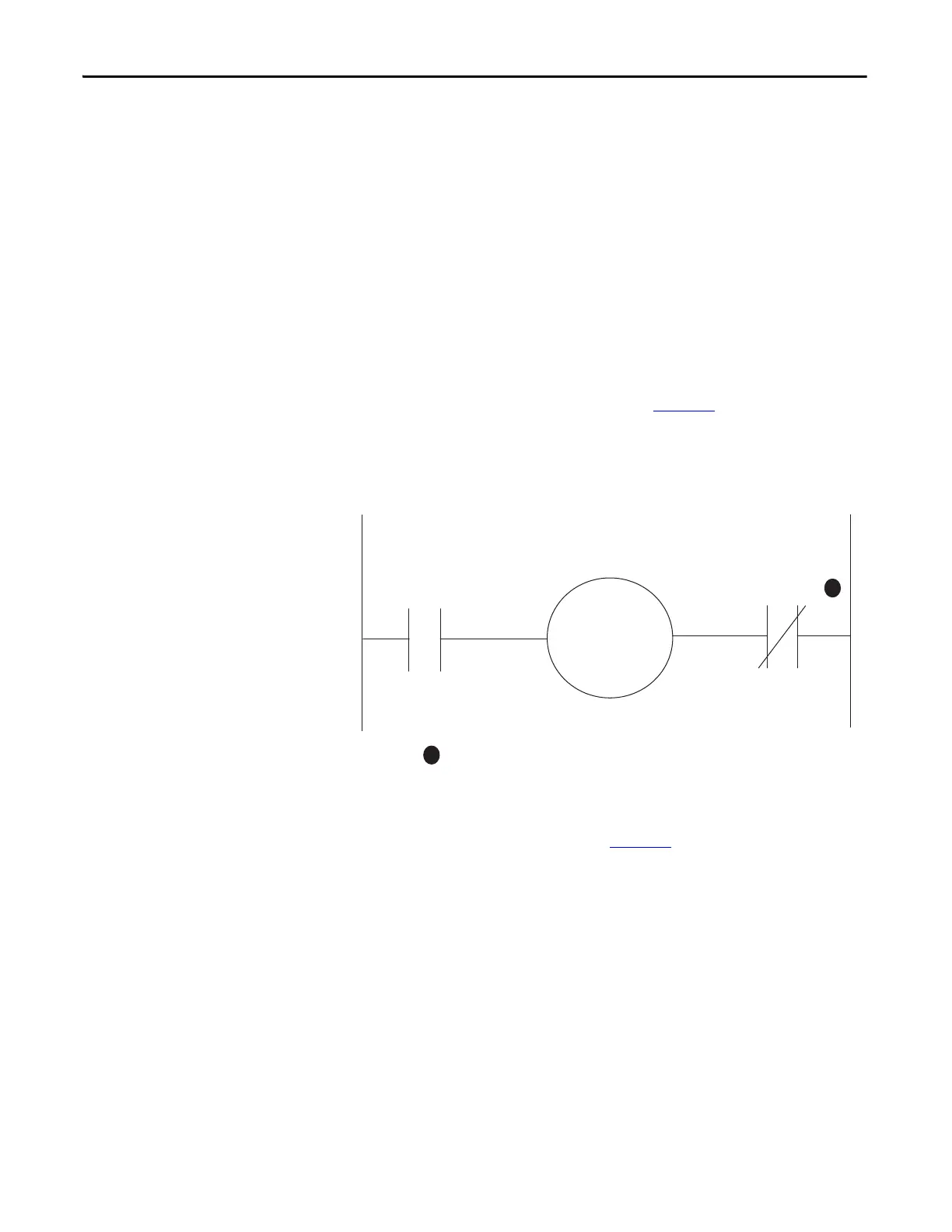

For Control Module firmware v3.000 and higher, the E300 relay can also be

wired as a control relay so that the relay that is controlled by the communication

network opens when a trip event occurs. Figure 56

is a wiring diagram of a non-

reversing starter with Relay 0 configured as a control relay. Relay 0 receives

control commands from an automation controller to energize or de-energize the

contactor coil. Relay 0 also goes to an open state when there is a trip event.

Relay 1

Relay 0

Configured as a

Trip Relay

R13 R14

A1

A2

M

R03

R04

1

1

Contact shown with supply voltage applied.

Loading...

Loading...