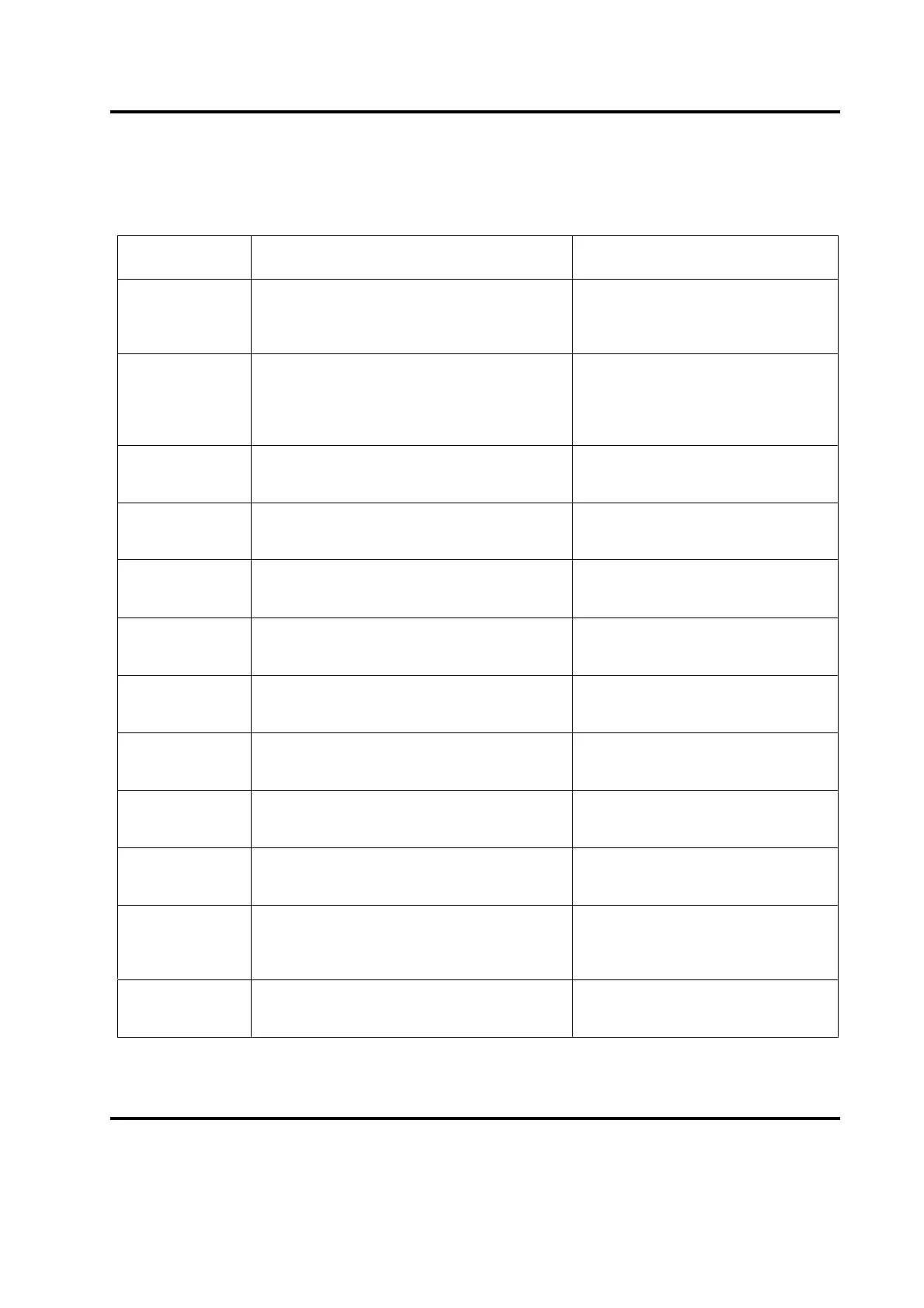

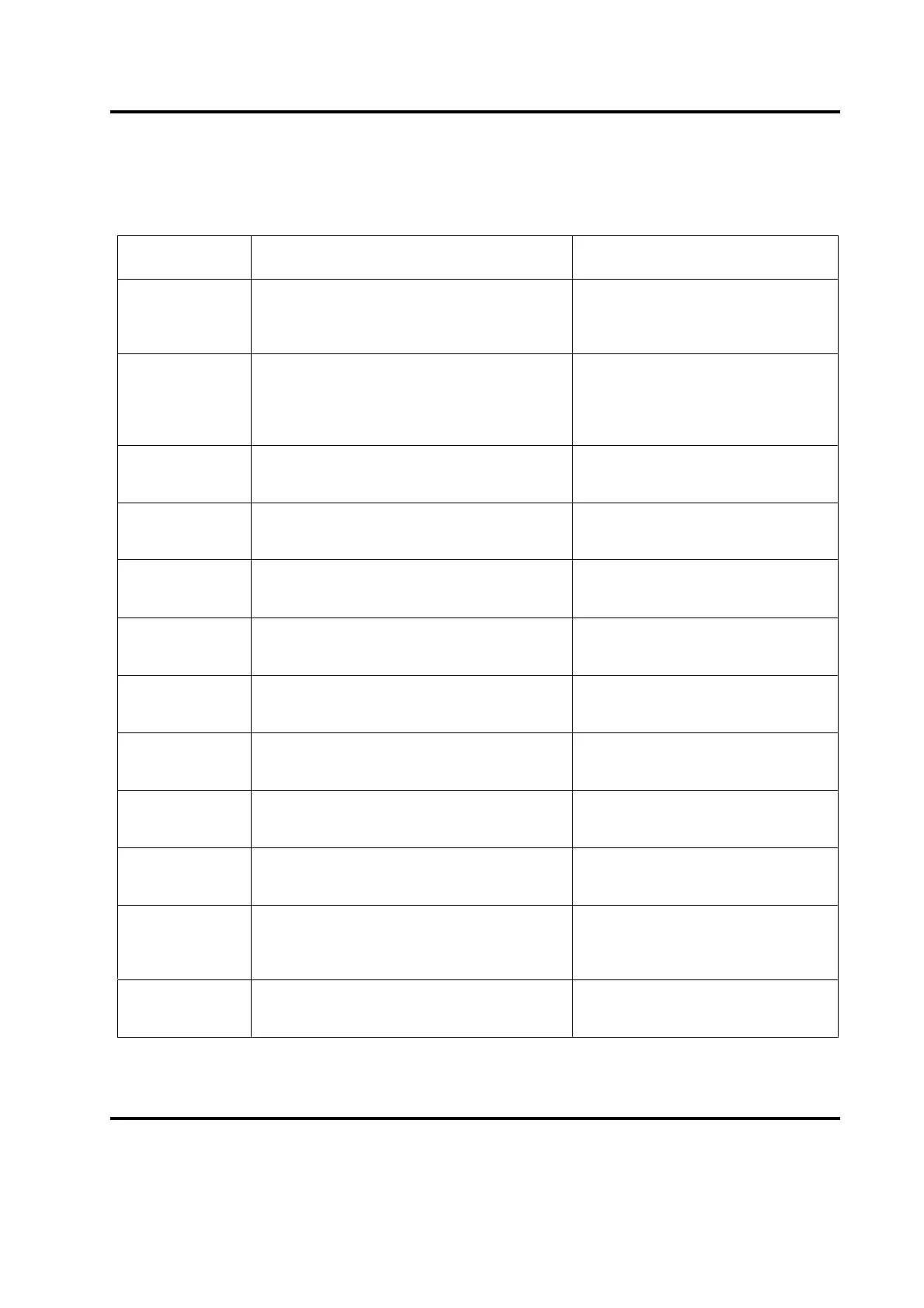

2000X energy Power Supply Chapter 7: Maintenance

Instruction Manual System Alarm Tables

011-003-991 EN 7-35

Weld Force >

pressure

The weld force was entered when the system

pressure was 80 psi. The system pressure has

been reduced to 60 psi and the requested force

cannot be reached.

Re-enter the weld force value or go into

horndown and increase the pressure to

80 psi.

2000a

2000dt

2000e

2000t

Invalid Preset

Error Code = 1

Features have been selected that are not valid for

this control level. Includes things that could have

been selected through host mode or selected by

installing a BBR from a higher control level

machine.Specific to Error code 1: MPS.

Currently, MPS is not available.

Invalid Preset

Error Code = 2

Refer to text in first Invalid Preset entry. Specific to

Error code 2: Amplitude stepping on Control Level

1 or 2

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 3

Refer to text in first Invalid Preset entry. Specific to

Error code 3: Force stepping on Control Level 1, 2,

3 or 4

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 4

Refer to text in first Invalid Preset entry. Specific to

Error code 4: Using a weld mode not valid for

Control Level.

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 5

Refer to text in first Invalid Preset entry. Specific to

Error code 5: Invalid distance.

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 6

Refer to text in first Invalid Preset entry. Specific to

Error code 6: Invalid force.

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 7

Refer to text in first Invalid Preset entry. Specific to

Error code 7: Version incorrect.

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 8

Refer to text in first Invalid Preset entry. Specific to

Error code 8: Control level or actuator incorrect.

Change the settings in your preset.

A cold start may be needed.

Invalid Preset

Error Code = 9

Refer to text in first Invalid Preset entry. Specific to

Error code 9: No association of DUPS preset to the

current COP preset.

Change the settings in your preset.

A cold start may be needed.

2000dt Abs Cutoff Conflict The absolute cutoff

distance is equal to or less than the minus reject

absolute limit.

Change the absolute cutoff distance or

- reject absolute distance limit through

the Alarm Information screen or Setup

menu.

2000dt Abs Cutoff Conflict The absolute cutoff

distance is equal to or less than the minus reject

trigger limit.

Change the absolute cutoff distance or

- reject trigger distance limit through the

Alarm Information screen or Setup menu.

Table 7.8 Setup Alarms and Messages, with Probable Cause

and Corrective Action (Continued)

Model

Display

Message

Alarm Condition/Cause Corrective Action

Loading...

Loading...