Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 11

Unidrive SP Advanced User Guide 187

Issue Number: 7 www.controltechniques.com

will be initiated. It should be noted that in both cases the parameters held in drive parameter RAM are likely to be incorrect.

During SMARTCARD or EEPROM data transfer the user will not be able to exit keypad edit mode when the current parameter is in menu 0.

Parameter data block when 3yyy is used to transfer data to a card

The data blocks contain the complete data from the drive EEPROM, i.e. all user save (US) except the parameters with the NC coding bit set. Power-

down save (PS) are not saved to the SMARTCARD. A SMARTCARD can hold up to 4 data blocks of this type.

When the data is transferred back to a drive, using 6yyy in Pr x.00, it is transferred to the drive RAM and drive EEPROM. A parameter save is not

required to retain the data after power-down. (When parameters are copied to the drive RAM this action is performed twice to prevent interdependent

parameters from being copied incorrectly.) Before the data is taken from the card, defaults are loaded in the destination drive using the same default

code as was last used in the source drive.

The categories of modules fitted to the card data source drive are stored on the card. If these are different from the destination drive, the menus for

the slots where the Solutions Module categories are different, are not modified and so they will contain their default values, and the drive will produce

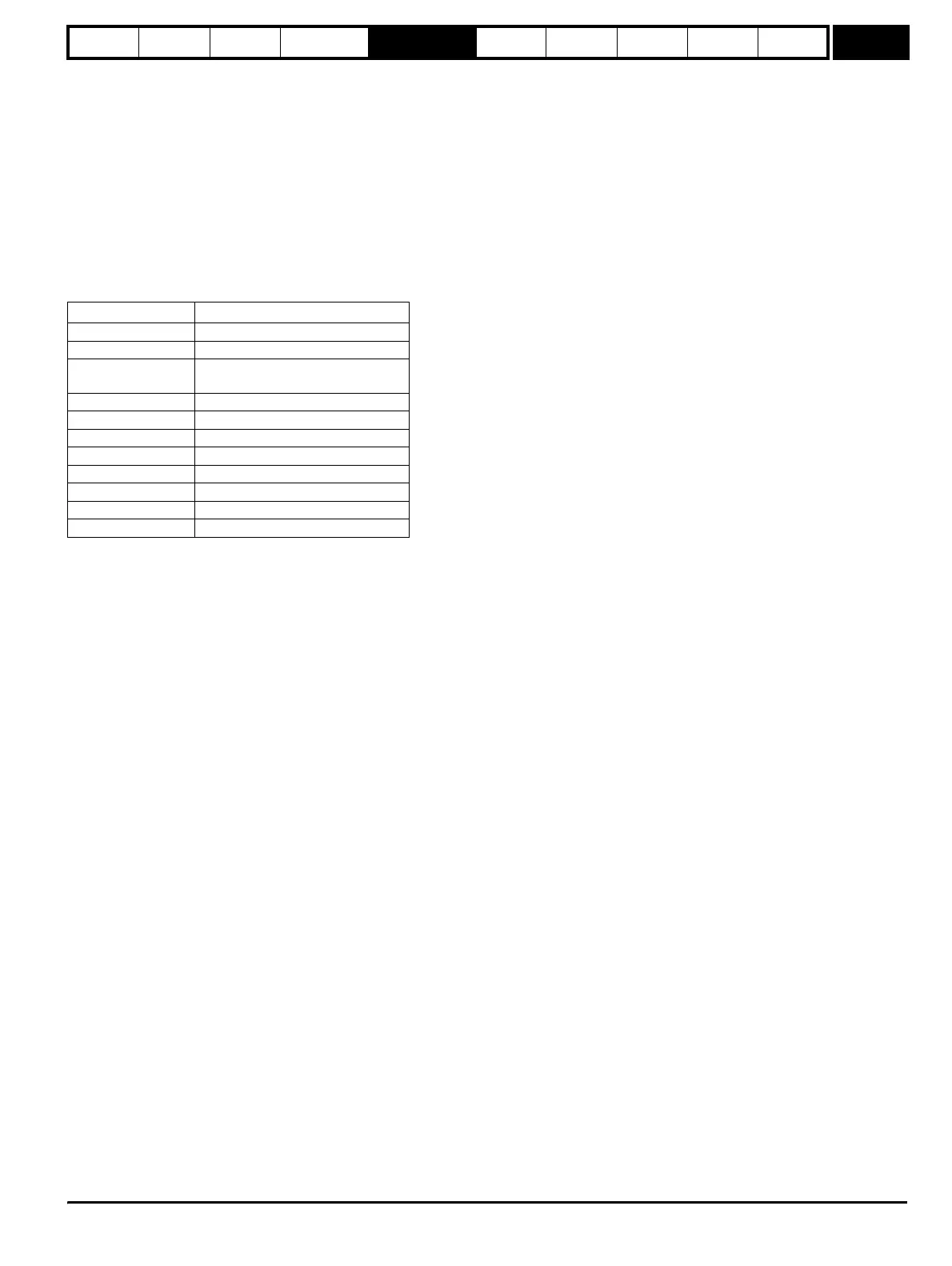

a C.Optn trip. If the data is transferred to a drive of a different voltage, or current rating from the source drive, all parameters with the RA coding bit set

(as given in the table below) are not modified and a C.rtg trip occurs.

A compare action on this data block type, setting 8yyy in Pr x.00, will compare the SMARTCARD data block with the data in the EEPROM. If the

compare is successful Pr x.00 is simply set to 0. If the compare fails a C.cpr trip is initiated.

Parameter data block when 4yyy is used to transfer data to a card

The only parameter data stored on the SMARTCARD is the number for the last set of defaults loaded and the differences from the last defaults

loaded. This requires six bytes for each parameter difference. The data density is not as high as when using the data format described in the previous

section, but in most cases the number of differences from default is small and the data blocks are therefore smaller. This method can be used for

creating drive macros. Parameters that are not transferred when using 3yyy are also not transferred with this method. Also parameters that do not

have a default value (attribute ND is set) cannot be transferred with this method (i.e. Pr 3.25 or Pr 21.20 which are the servo mode phasing angle

have no default value). Parameter RAM is used as the source of this information.

When the data is transferred back to a drive, using 6yyy in Pr x.00, it is transferred to the drive RAM and the drive EEPROM. A parameter save is not

required to retain the data after power-down. (When parameters are copied to the drive RAM this action is performed twice to prevent interdependent

parameters from not being set correctly.) The categories of modules fitted to the card data source drive are stored on the card. If these are different

from the destination drive, the menus for the slots where the Solutions Module categories are different are not modified and will contain their default

values, and the drive will produce a C.Optn trip if any of the parameters from the card are in the option menus. If the data is transferred to a drive of a

different voltage or current rating from the source drive then parameters with the RA coding bit set (see table above) will not be written to the drive and

these parameters will contain their default values. The drive will produce a C.rtg trip whether any of the parameters from the card are parameters with

the RA coding bit set or not if the current or voltage rating are different.

A compare action on this data block type, setting 8yyy in Pr x.00, will compare the SMARTCARD data block with the data in the drive RAM. If the

compare is successful Pr x.00 is simply set to 0. If the compare fails a C.cpr trip is initiated.

Drive Onboard PLC program data blocks

The Onboard PLC program from a drive may be transferred to/from internal flash memory from/to a SMARTCARD. If the ladder program is

transferred from a drive with no ladder program loaded the block is still created on the card, but contains no data. If this is then transferred to a drive,

the drive will then have no ladder program. A SMARTCARD has a capacity of 4K bytes and each block of this type can take up to 4K bytes.

SMARTCARD compare function

If 8yyy is entered in Pr x.00 and the drive is reset, data block yyy on the SMARTCARD is compared with the relevant parameters in the drive. If the

compare is successful Pr x.00 is simply set to 0. If the compare fails a C.cpr trip is initiated. This function can be used with all data block types except

type 18. If a compare is requested with data block type 18 the result will always be a C.cpr trip.

Parameter number Function

Pr 2.08 Standard ramp voltage

Pr 3.05 Regen unit voltage setpoint

Pr 4.05 to Pr 4.07,

Pr 21.27 to Pr 21.29

Current limits

Pr 5.07, Pr 21.07 Motor rated current

Pr 5.09, Pr 21.09 Motor rated voltage

Pr 5.17, Pr 21.12 Stator resistance

Pr 5.18 Switching frequency

Pr 5.23, Pr 21.13 Voltage offset

Pr 5.24, Pr 21.14 Transient inductance

Pr 5.25, Pr 21.24 Stator inductance

Pr 6.06 DC injection braking current

http://nicontrols.com

Loading...

Loading...