Menus 15 to 17

Fieldbus

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

282 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

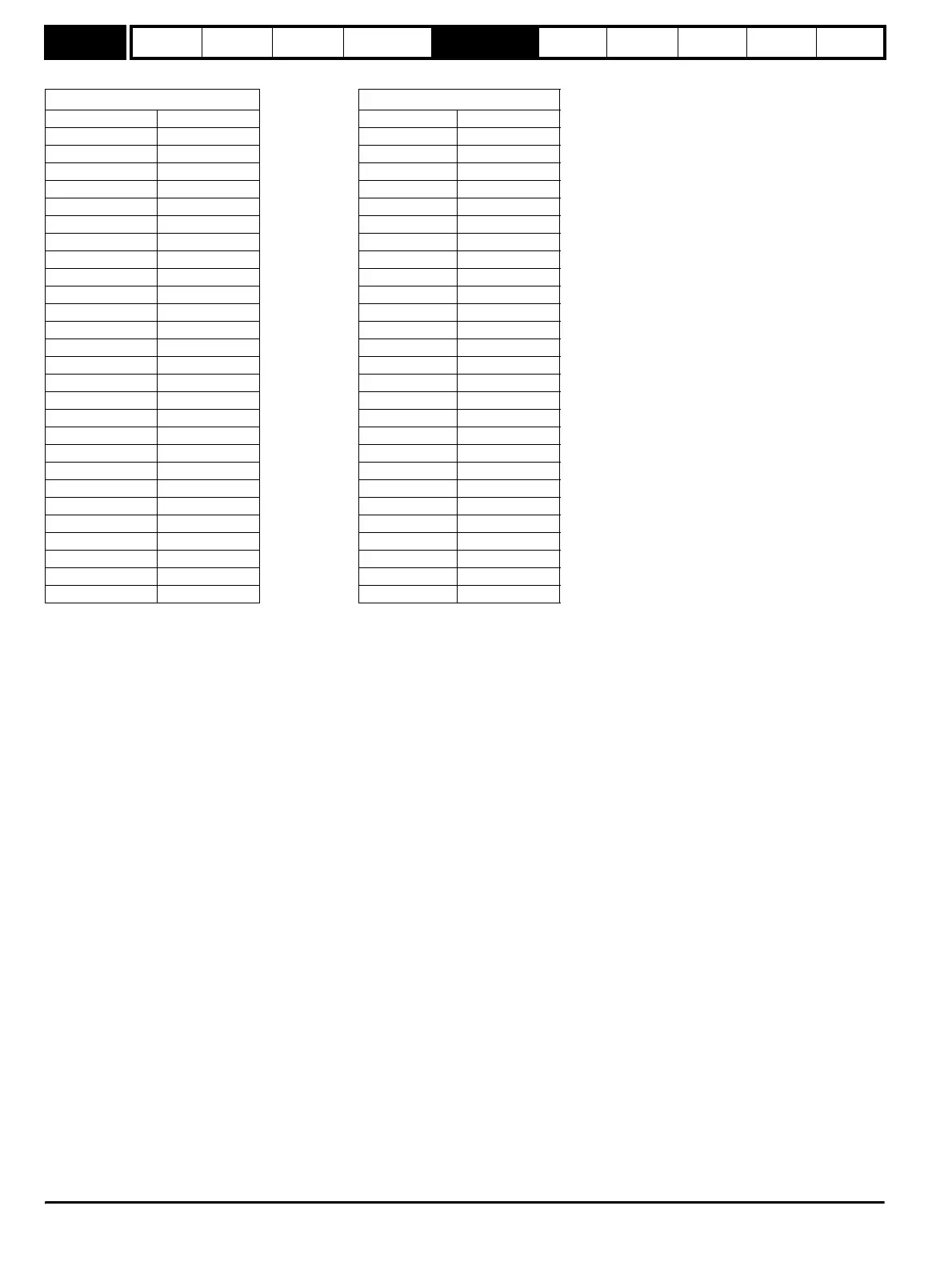

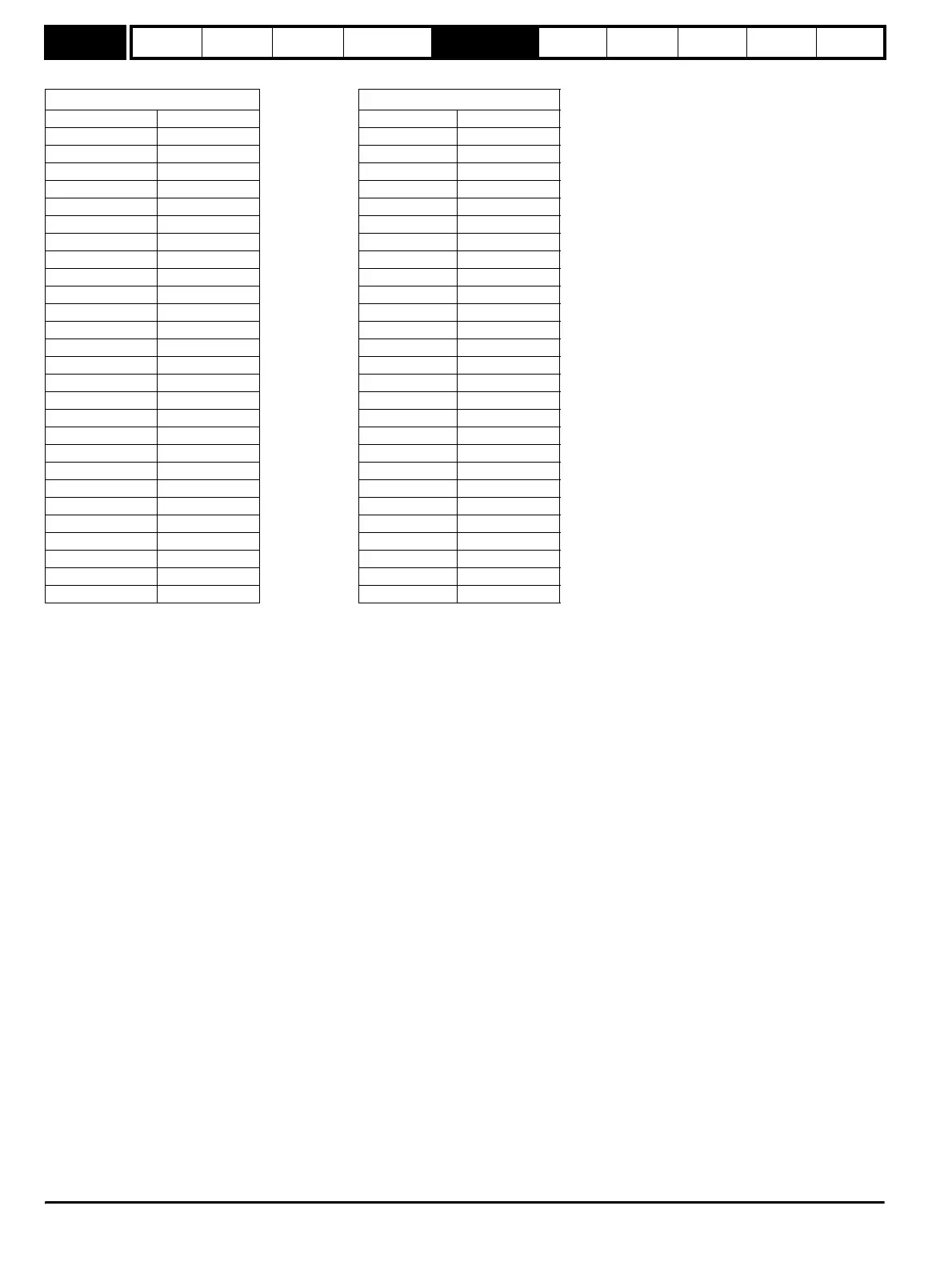

Table 5-12 Resulting Data Structure

Inter-option communication handling

When SM-Applications parameters are mapped (except direct access to set-up menu 15,16 or 17) the data transfer takes place through the inter-

option communications channel. This channel gives complete access to all SM-Applications parameters but due to the nature of the transfer method

transferring multiple parameters this way can be slow. The server (SM-Applications) polls the client (fieldbus module) every 1ms looking for a new

request. Only one request can be carried out on each poll, therefore to transfer 10 parameters individually will take approximately 10ms.

To reduce the speed problem data can be transferred in blocks. A block consists of up 10 words of data from consecutive parameters from in a single

SM-Applications PLC menu (all PLC menus parameters are treated as 32bit, so up to 5 parameters per block). To reduce overhead in block transfers

mapping information for a block is sent to the SM-Applications during initialisation, once cyclic data transfer starts block data is sent or received

without the need for mapping information. There are 8 input, and 8 output, blocks available to provide up to 80 words in each direction (more than is

currently required).

Blocks are only set up for ranges of 2 or more SM-Applications PLC mappings. A single parameter is always transferred using the standard transfer

method, as there is no speed advantage in using up a block. Large ranges will span across multiple blocks, however if after creating a block only a

single parameter remains it will be mapped using the single transfer method. For example a range of 7 PLC parameters will use a full block of 5 and

a block containing 2 parameters whereas a range of 11 PLC parameters will use up 2 full blocks and a single transfer. Fewer but larger ranges are

therefore more efficient that multiple smaller ranges.

With only 10 mapping parameters (once expanded up to 32 words can be mapped) available to the user it is only possible to create up to 5 ranges.

For this reason the maximum number of blocks that can currently be used is 6 (4 ranges of 2 parameters and 1 range of 8), although 8 blocks are

available.

Timeout Trips:

If inter-option communication is in use and the server (e.g. SM-Applications) is reset but no reset request has been made to the client then a client

timeout trip will occur.

If both the client and server are reset (e.g. by 1070 being set in Pr x.00) no trip will occur, both will reset and communication will restart.

If the client is reset (e.g. by Pr x.31 in a fieldbus setup menu being set to 1) the client will restart, no trip will occur and the server will continue normal

operation.

In Data Out Data

Word 0 Pr 10.40 Word 0 Pr 6.42

Word 1 Pr 2.01 Word 1 Pr 1.21

Word 2 Pr 2.01 Word 2 Pr 1.21

Word 3 Pr 4.20 Word 3 Pr 4.08

Word 4 Pr 130.11 Word 4 Pr 4.08

Word 5 Pr 130.11 Word 5 Pr 130.01

Word 6 Pr 130.12 Word 6 Pr 130.01

Word 7 Pr 130.12 Word 7 Pr 130.02

Word 8 Pr 130.13 Word 8 Pr 130.02

Word 9 Pr 130.13 Word 9 Pr 130.03

Word 10 Pr 130.14 Word 10 Pr 130.03

Word 11 Pr 130.14 Word 11 Pr 130.04

Word 12 Pr 130.15 Word 12 Pr 130.04

Word 13 Pr 130.15 Word 13 Pr 130.05

Word 14 Pr 71.03 Word 14 Pr 130.05

Word 15 Pr 71.03 Word 15 Pr 131.03

Word 16 Pr 160.11 Word 16 Pr 131.03

Word 17 Pr 160.11 Word 17 Pr 160.01

Word 18 Pr 160.12 Word 18 Pr 160.01

Word 19 Pr 160.12 Word 19 Pr 160.02

Word 20 Pr 160.13 Word 20 Pr 160.02

Word 21 Pr 160.13 Word 21 Pr 160.03

Word 22 Pr 160.14 Word 22 Pr 160.03

Word 23 Pr 160.14 Word 23 Pr 160.04

Word 24 Pr 160.15 Word 24 Pr 160.04

Word 25 Pr 160.15 Word 25 Pr 160.05

Word 26 - Word 26 Pr 160.05

Word 27 - Word 27 -

http://nicontrols.com

Loading...

Loading...