S0605050K

Page 22

Air Conditioner

Return to Master Table of Contents

2. Check system for vacuum leak.

Allow system to sit for 10 minutes and

check whether the system is holding the

pressure. If the pressure has dropped, it

must be repaired before proceeding to the

next step.

3. Vacuuming Procedure.

If the system is holding the pressure and it

has not changed for 10 minutes, vacuum

out the system for an additional 20

minutes.

A. Turn on the vacuum pump and slowly

open both valves.

B. Allow vacuum pump to run for additional 20 minutes until the low pressure gauge dial reads

approximately 750 mmHg.

C. Close both valves and stop the vacuum pump.

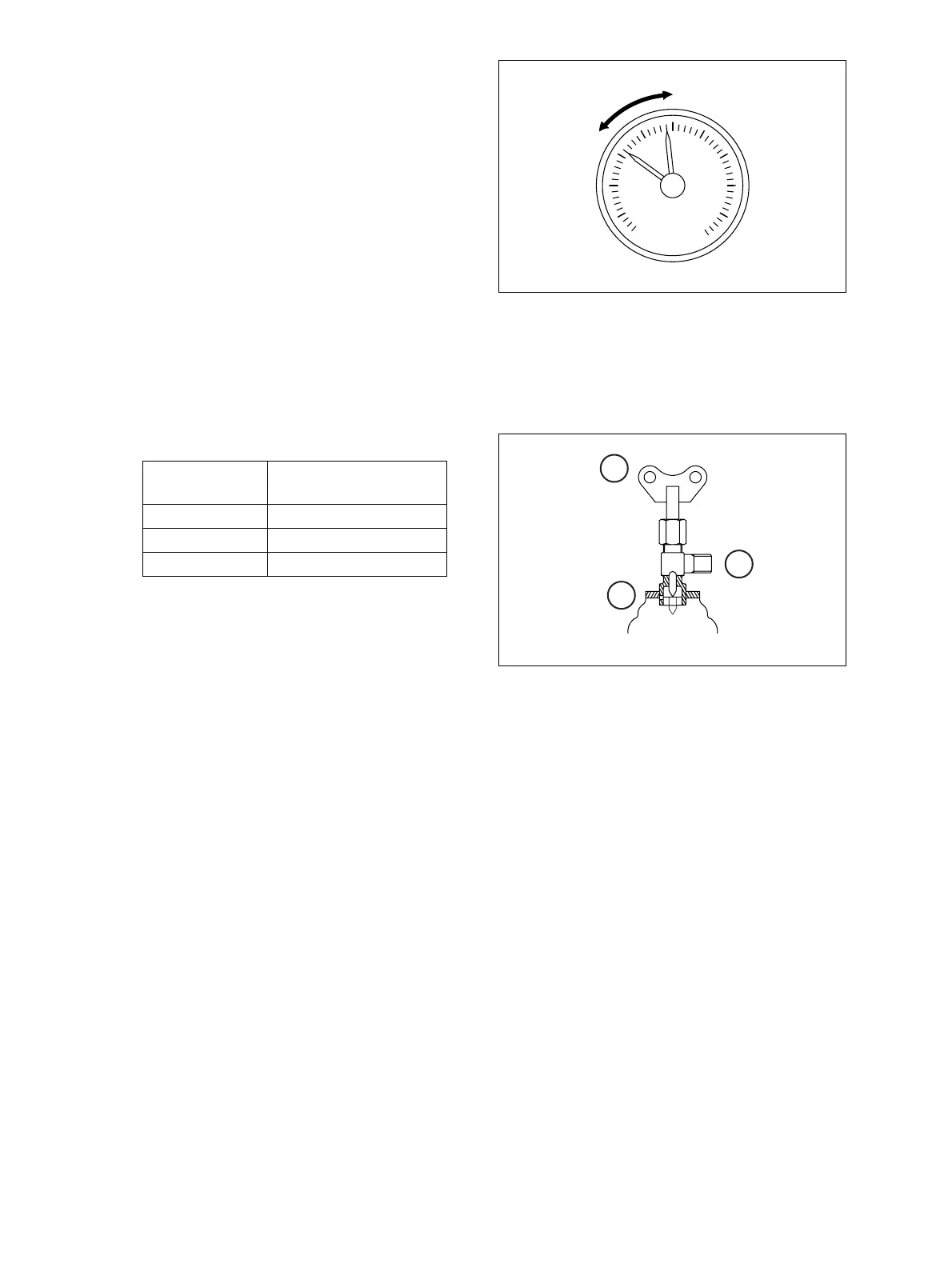

4. Installation Of Refrigerant Container.

A. Before mounting valve on the

container, make sure the handle is in

the counterclockwise most position,

with the puncture pin retracted and

the mounting disk is in the raised

position.

B. Attach the manifold gauge center

hose to the valve assembly.

C. Turn the disc in the clockwise direction and securely mount valve onto refrigerant container.

D. Turn the valve handle in the clockwise direction and puncture the container seal with the pin.

E. Once the can has been punctured, turn the handle in the counter clockwise direction so the

refrigerant can flow into the manifold gauge center hose. At this time, do not open the low and

high pressure valves of the manifold gauge.

F. Press the manifold gauge low side valve to eliminate the trapped air in the hose.

LEAKAGE CHECK

NOTE:

Perform the leakage check after completing vacuuming process.

1. After attaching the manifold gauge, open the high side valve.

2. Charge system until the low side gauge dial indicates a pressure of 1 kg/cm

2

(14 psi) and close the

high side valve.

Reference

Number

Description

1 Handle

2 Hose Connection

3 Mounting Disk

HDA6069L

Figure 18

1

2

3

HDA6070L

Figure 19

Loading...

Loading...