S0708470K

Page 16

Steering and Brake Pump (Denison T67DB Series)

CLEANING AND INSPECTION (WEAR LIMITS AND

TOLERANCES)

For general cleaning and inspection procedures, refer to "General Maintenance Procedures" section.

CLEANING

All parts must be thoroughly cleaned and kept clean during inspection and assembly. Contamination of unit

will cause excessive wear, leakage, and decreased service life. Use a commercial solvent which is

compatible with the system fluid. Thoroughly clean all parts. Drying parts with compressed air after

cleaning is not recommended, unless the air is completely filtered to remove water and contamination.

INSPECTION, REPAIR AND REPLACEMENT

Check all internal passages. Make sure they are clean and unobstructed. Examine all mating surfaces for

nicks and burrs. Check locating pins and holes for wear and burrs. Check the condition of threaded parts

and threaded holes. Check all snap ring recesses. Minor burrs can be removed with an India stone.

Replace any part which shows wear or damage. The following parts are subject to special attention:

1. Cartridge kits (39 and 40). to obtain

maximum overhaul life of the pump, a

complete cartridge kit should be installed if

wear or scoring is noticed during the

following inspection steps.

A. Inspect the mating surfaces of the

rotors (15 and 28), outlet support

plates (17 and 30), and inlet support

plates (12 and 25) for wear and/or

scoring.

B. Inspect vanes and inserts (16 and

29) for burrs, wear, and play in slots

of rotors (15 and 28). Remove minor

burrs with an India stone.

NOTE:

DO NOT

use a dry stone on

bronze surfaces or scratches will result

C. Inspect bushing for wear and scoring.

2. Check bearing (33) for wear, looseness, and pitted or cracked races.

3. Inspect seal and bushing mating surfaces on the shaft for scoring and wear. Replace shaft if marks

cannot be removed by light polishing.

4. Remove burrs from outer edge of ring (27). Place rotor (15) and ring (27) on a flat surface. Measure

ring/rotor clearance with a dial indicator. Ring/rotor clearance are noted in Table below.

Model Minimum Clearance Limit In Inches

T67DB - 1308 0.018 mm (0.0007 in)

T67DB - 031 0.038 mm (0.0015 in)

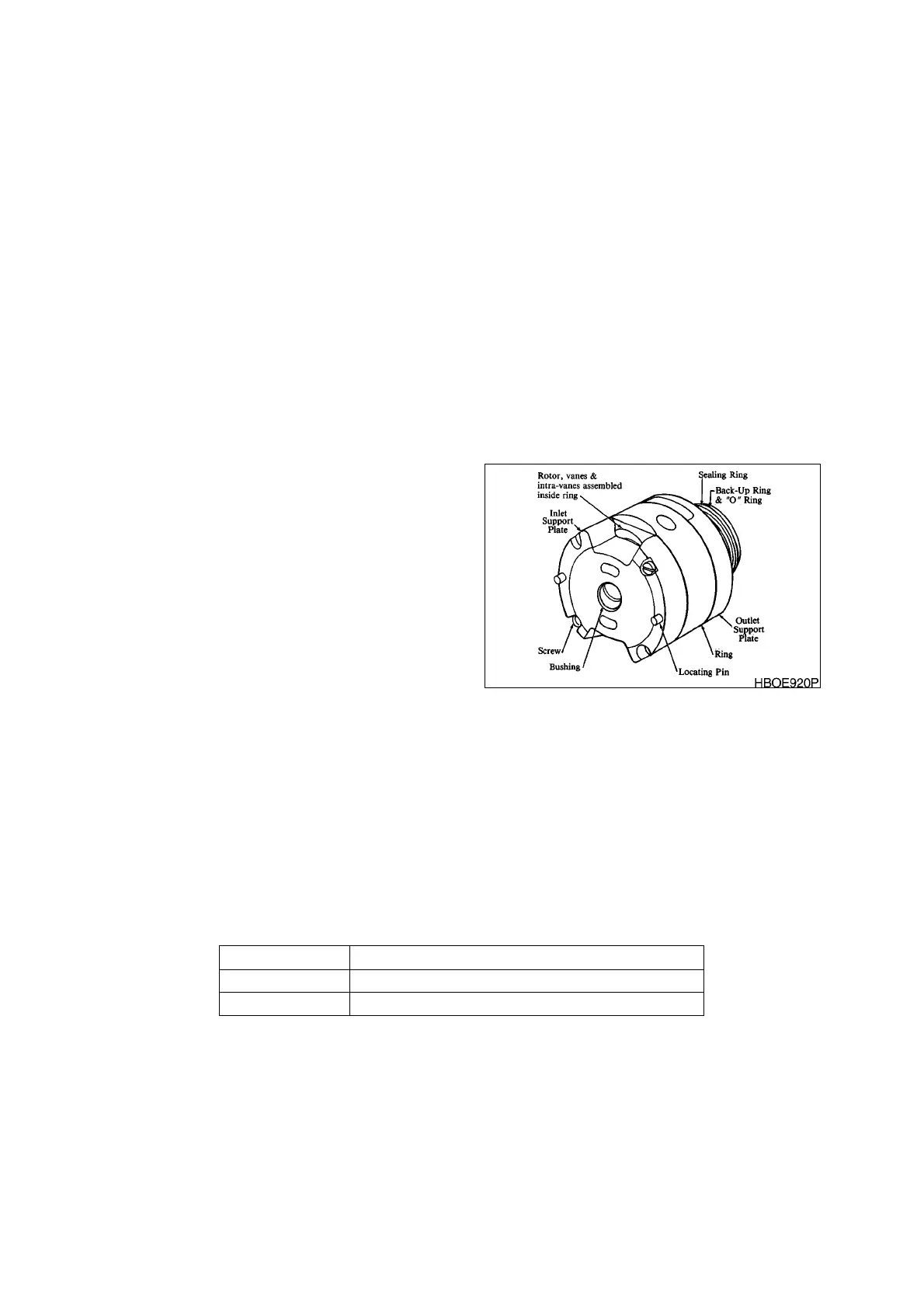

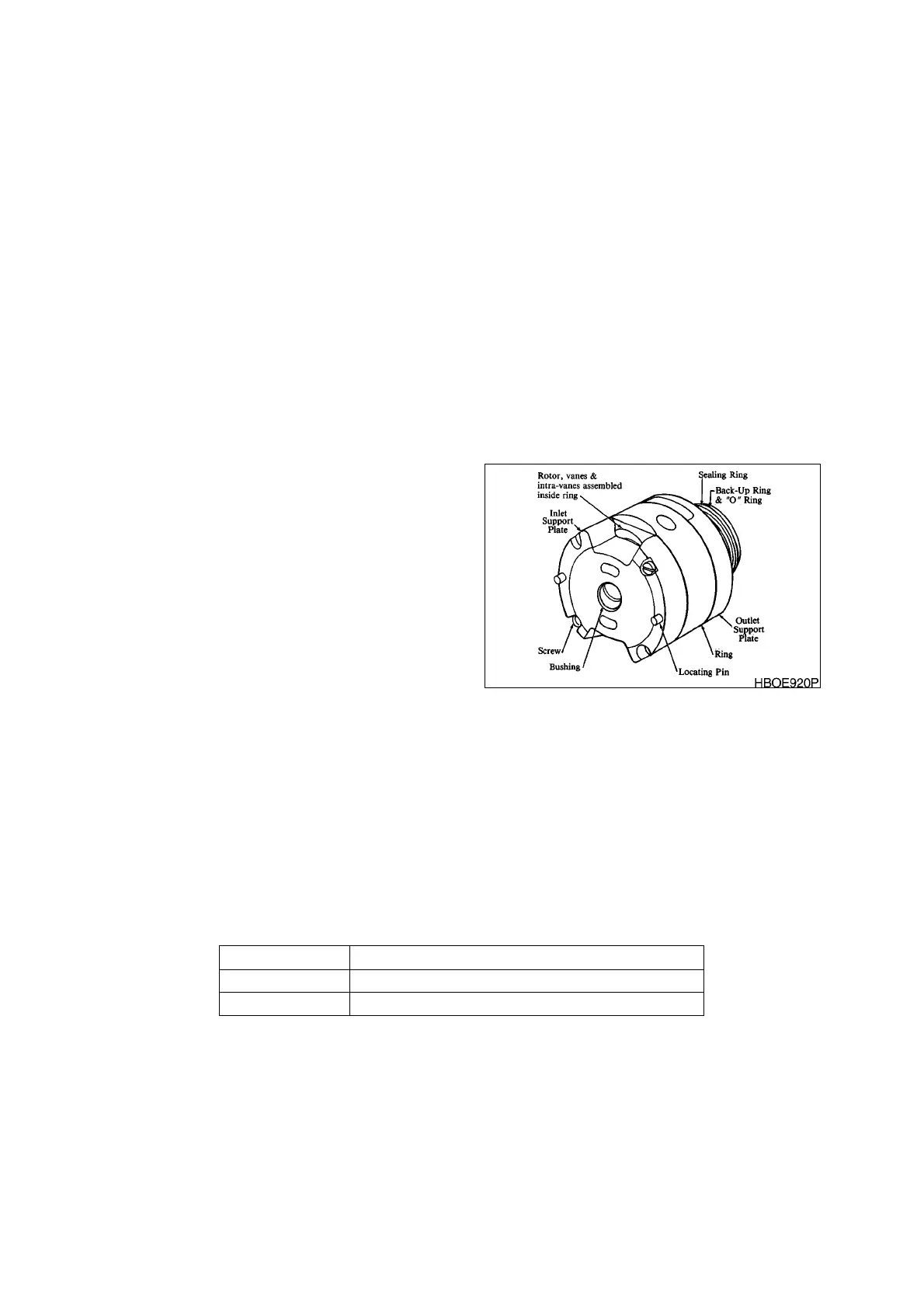

Figure 14 PREASSEMBLED CARTRIDGE

Loading...

Loading...