S0708460K

Page 14

Main Pump (Denison T6DMY Series)

SPECIAL TOOLS AND MATERIALS

SPECIAL TOOLS

Two special tools are required to service these pumps. A driver should be used to assure installation of the

primary shaft seal without damage, and a "bullet" should be placed over the end of the shaft, to avoid

damaging the seal lip when the shaft is installed. Installation of the secondary seal does not require a

driver. (See Figure 6.)

NOTE:

If a shaft seal bullet is unavailable, wrap splines on shaft with masking tape to prevent

damage to seal. Coat tape with oil while installing shaft. Be sure to remove all tape after

installation.

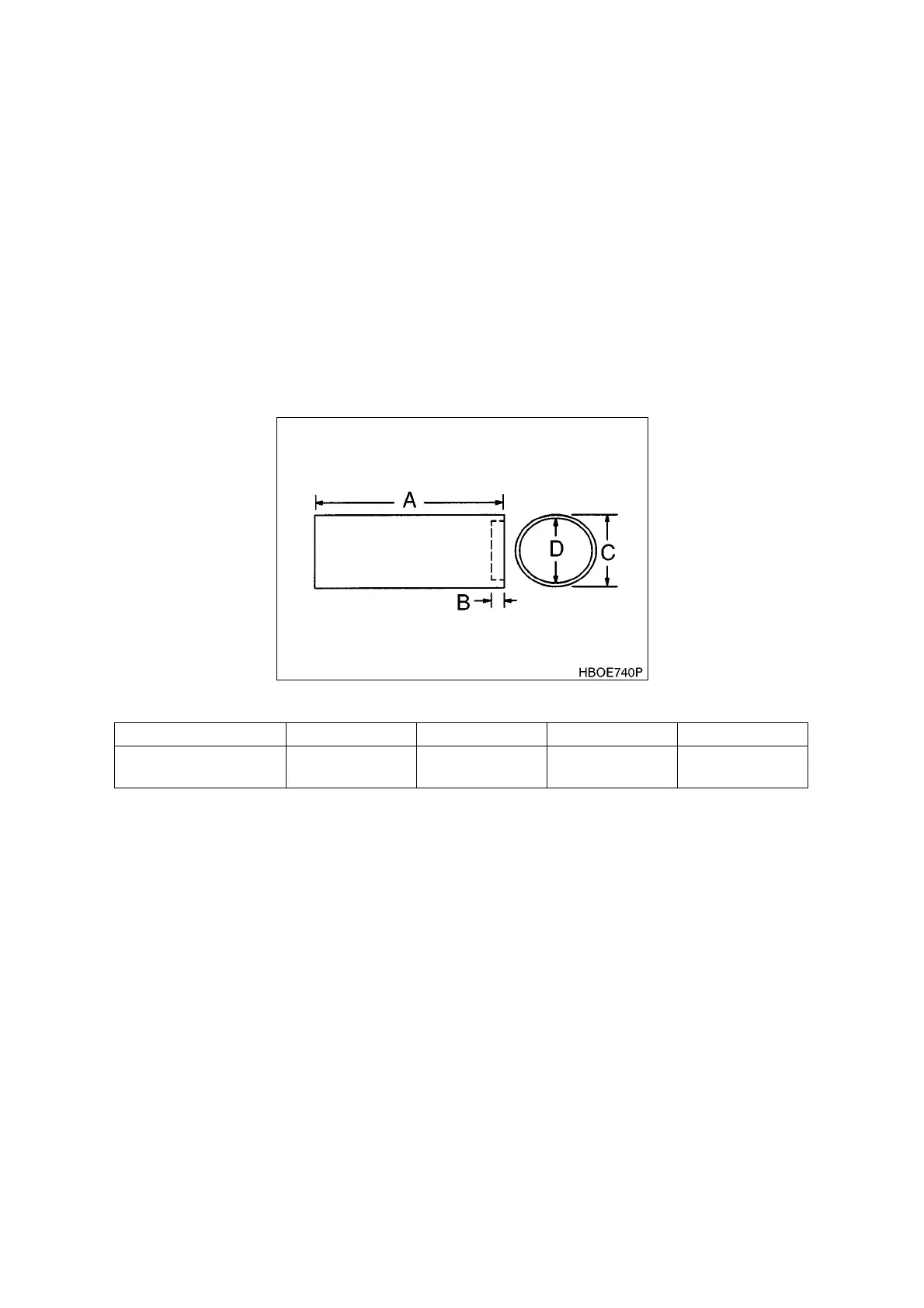

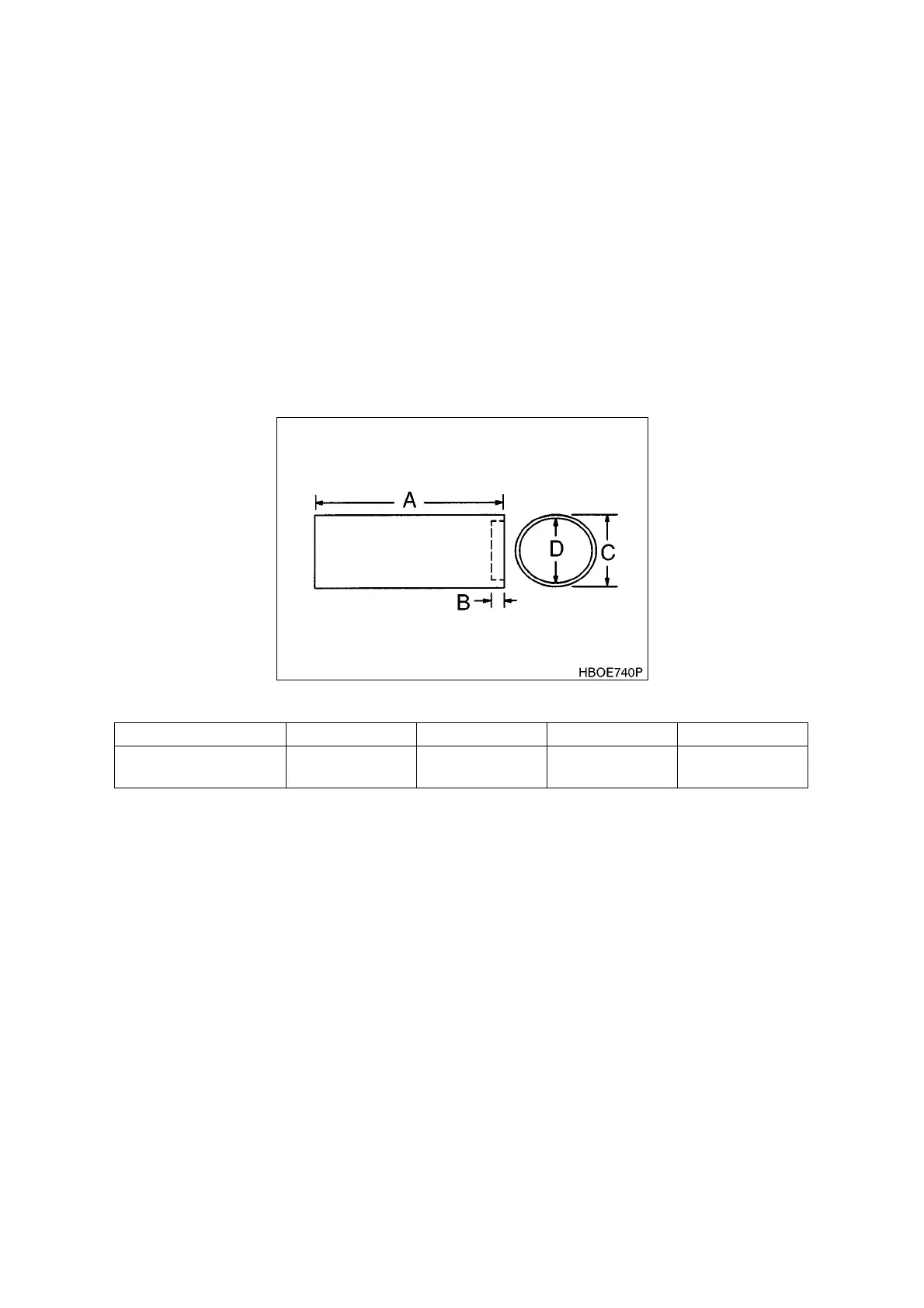

The driver can be made from tubular stock as shown in Figure 9. The tool applies a uniform pressure to the

recessed area of the seal, rather than to the lip of the seal. The inside diameter of the tool will not interfere

with the garter spring around the lip of the seal.

Pump Series Length "A" Undercut "B" O.D. "C" I.D. "D"

T6DMY-038 88.9 mm

(3.500 in)

8.407 mm

(0.331 in)

44.831 mm

(1.765 in)

41.199 mm

(1.622 in)

Figure 9 PRIMARY SHAFT SEAL DRIVER

Loading...

Loading...