S0708460K

Page 15

Main Pump (Denison T6DMY Series)

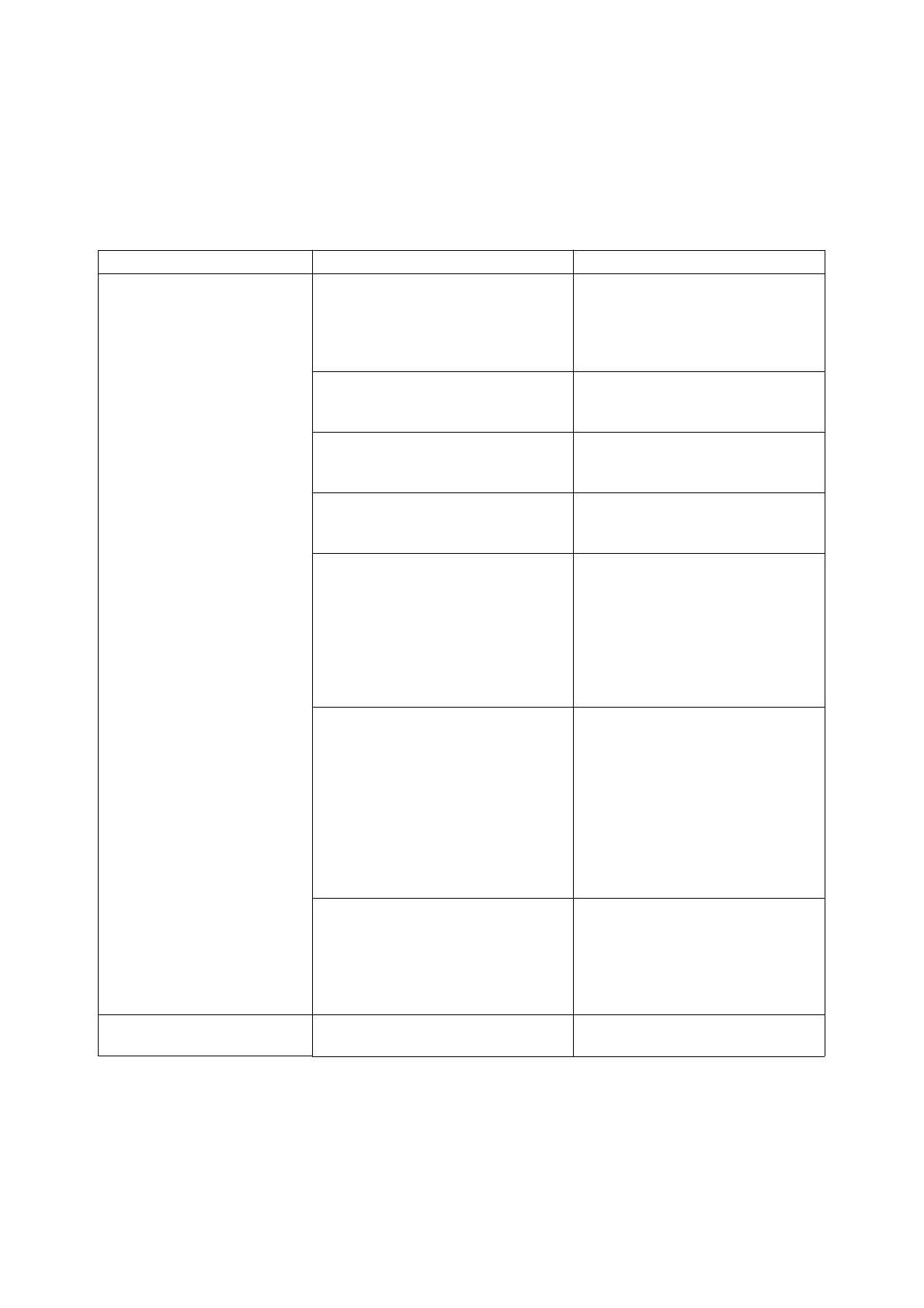

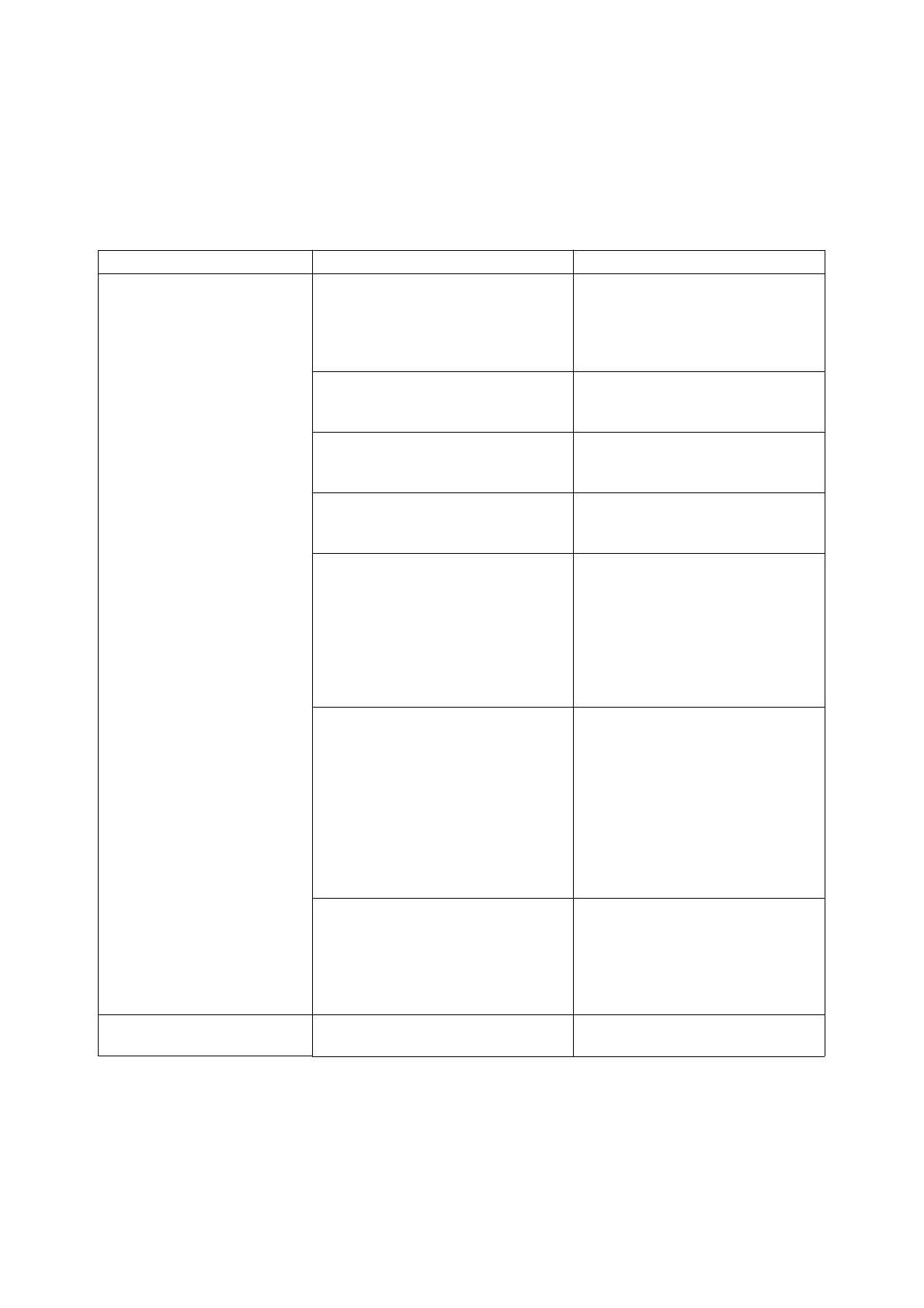

TROUBLESHOOTING, TESTING AND ADJUSTMENT

The following table lists common difficulties experienced with vane pumps and hydraulic systems. It also

indicates possible causes and remedies for each of the problems listed.

It should always be remembered that many apparent pump failures are actually the failures of other parts

of the system. The cause of improper operation is best diagnosed with adequate testing equipment and a

thorough understanding of the complete hydraulic system.

Problem Possible Cause Remedy

Pump not delivering fluid. Driven in wrong direction of

rotation.

The drive direction must be

changed immediately to prevent

seizure. Refer to “Reassembly” on

page -22, for correct ring position

for each direction of rotation.

Coupling or shaft sheared or

disengaged.

Disassemble pump and check

shaft and cartridge for damage.

Replace necessary parts.

Fluid intake pipe in reservoir

restricted.

Check all strainers and filters for

dirt and sludge. Clean if

necessary.

Fluid viscosity too heavy to pick up

prime.

Completely drain system. Add

new filtered fluid of proper

viscosity.

Air leaks at intake. Pump not

priming.

Check inlet connections to

determine where air is being

drawn in. Tighten any loose

connections. See that fluid in

reservoir, is above intake pipe

opening. Check minimum drive

speed which may be too slow to

prime pump.

Relief valve stuck open. (Models

with integral relief valve only).

Disassemble pump and wash

valve m clean solvent. Return

valve to its bore and check for any

stickiness. A gritty feeling on

valve periphery can be polished

with crocus cloth. Do not remove

excess material round off edges

of lands or attempt to polish bore.

Wash all parts and reassemble

pump.

Vane(s) stuck in rotor slot(s). Disassemble pump. Check for dirt

or metal chips. Clean parts

thoroughly and replace any

damaged pieces. If necessary,

flush system and refill it with clean

fluid.

Insufficient pressure build-

up.

System relief valve set too low. Use a pressure gage to correctly

adjust valve.

Loading...

Loading...