S0705010

Page 8

Cylinders

Return to Master Table of Contents

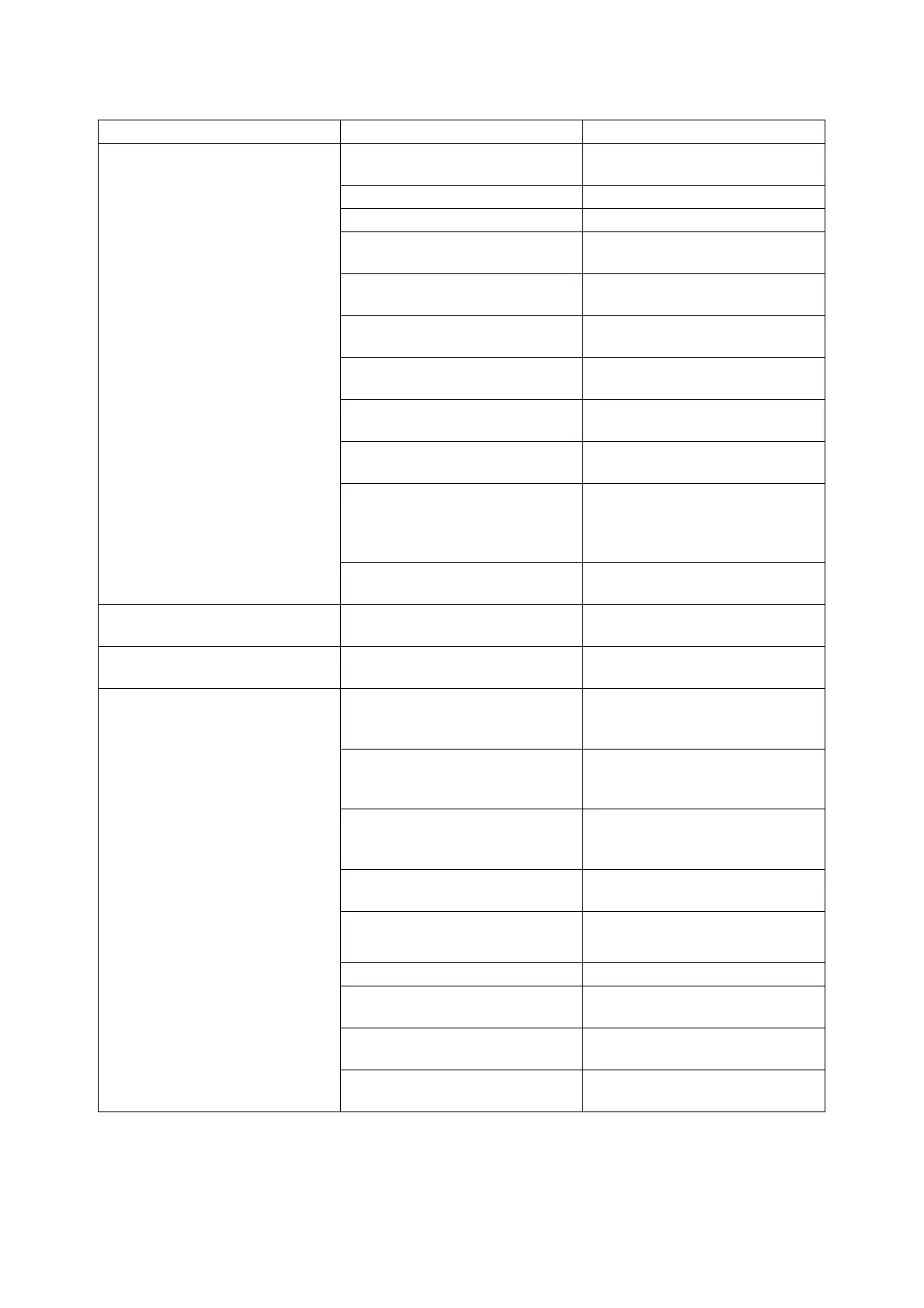

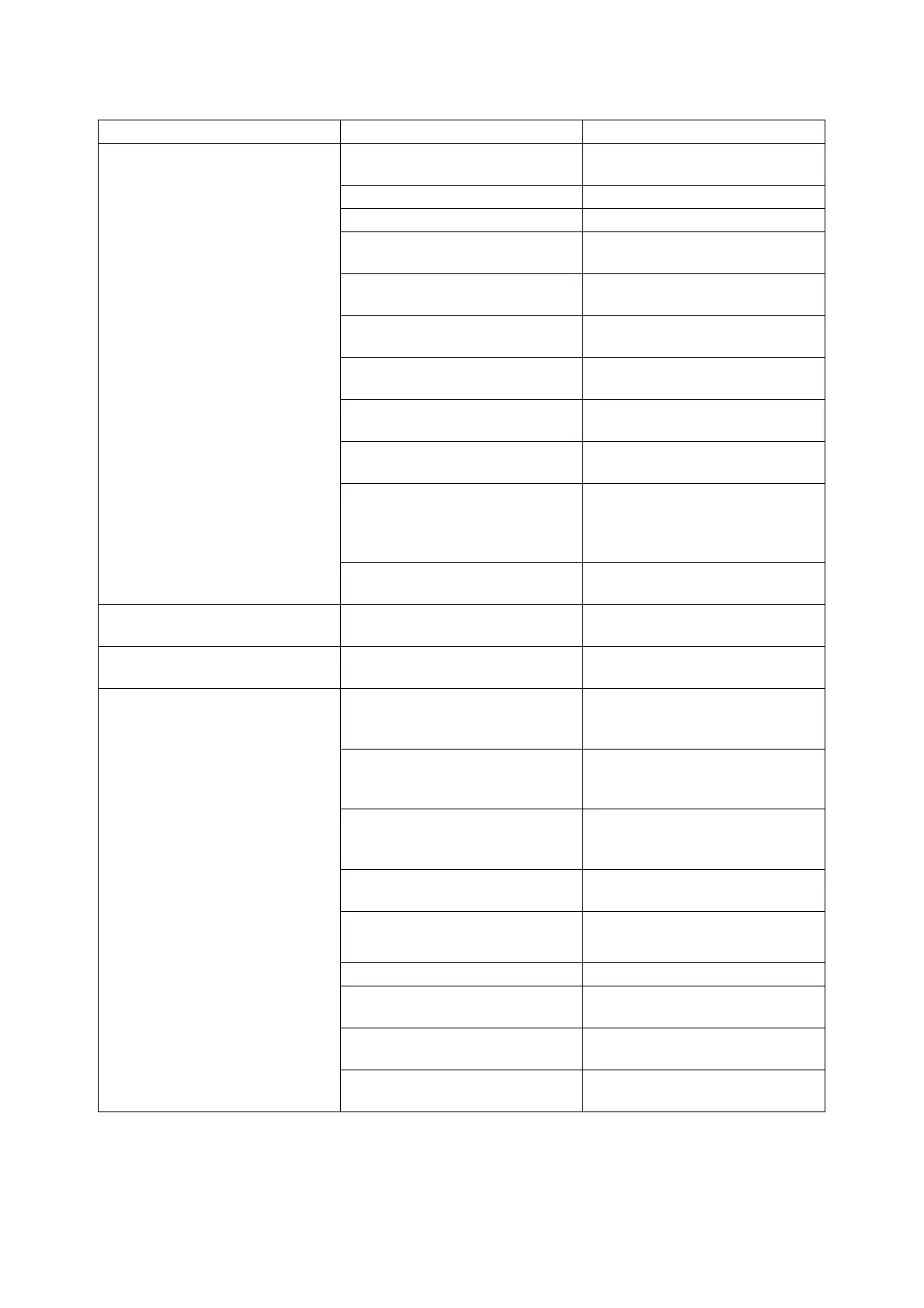

Problem Cause Remedy

Oil leaking between cylinder

head (16) and piston rod (18).

(Index nos. refer to Figure 1).

Foreign material in U-ring (3,

Figure 1)

Remove foreign material.

Scratches in U-ring (3, Figure 1). Replace U-ring (3).

Damage to U-ring (3, Figure 1). Replace U-ring (3).

Foreign material in dust seal (2,

Figure 1).

Remove foreign material.

Scratches in dust seal (2, Figure

1).

Replace dust seal (2).

Damage to dust seal (2, Figure

1).

Replace dust seal (2).

Foreign material in seal O-ring

(4, Figure 1).

Remove foreign material.

Scratches in seal O-ring (4,

Figure 1).

Replace O-ring (4).

Damage to seal O-ring (4,

Figure 1).

Replace O-ring (4).

Scratch on sealing surface of

piston rod (18, Figure 1).

If scratches are not deep, hone

with an oil stone and lubricate. If

scratches are deep, replace

piston rod (18).

Deep scratches on inner surface

of bushing (15, Figure 1).

Replace bushing.

Oil leaking between cylinder

head (16) and cylinder tube (13).

Damage to O-rings (14, Figure

1).

Replace O-rings (14).

Oil leaking from welded area of

cylinder tube (13).

Damage to welded area. Replace cylinder tube (13).

Cylinder drops from pull of

gravity.

Light scratches on sealing

surface of cylinder tube (13,

Figure 1).

Hone out scratches with oil

stone.

Deep scratches on sealing

surface of cylinder tube (13,

Figure 1).

Replace cylinder tube (13).

Deep scratches on sealing

surface of piston O-rings (10,

Figure 1).

Replace O-rings (10).

Foreign material in U-ring (3,

Figure 1).

Remove foreign material.

Scratches in U-ring (3, Figure 1). Replace U-ring (3).

Damage to U-ring (3, Figure 1). Replace U-ring (3).

Nylon wear rings (7, Figure 1)

twisted.

Replace nylon wear rings (7).

Nylon wear rings (7, Figure 1)

scratched.

Replace nylon wear rings (7).

Nylon wear rings (7, Figure 1)

have other damage.

Replace nylon wear rings (7).

Loading...

Loading...