Chapter 11 Motion Control Instructions

11-241

may decelerate to 0 and stay still for a while; and then accelerate up to the synchronous speed. The

greater the cutting length is, the longer the roller stays.

Additionally, when rotary cut function is started or broken off, the cam curves used are different.

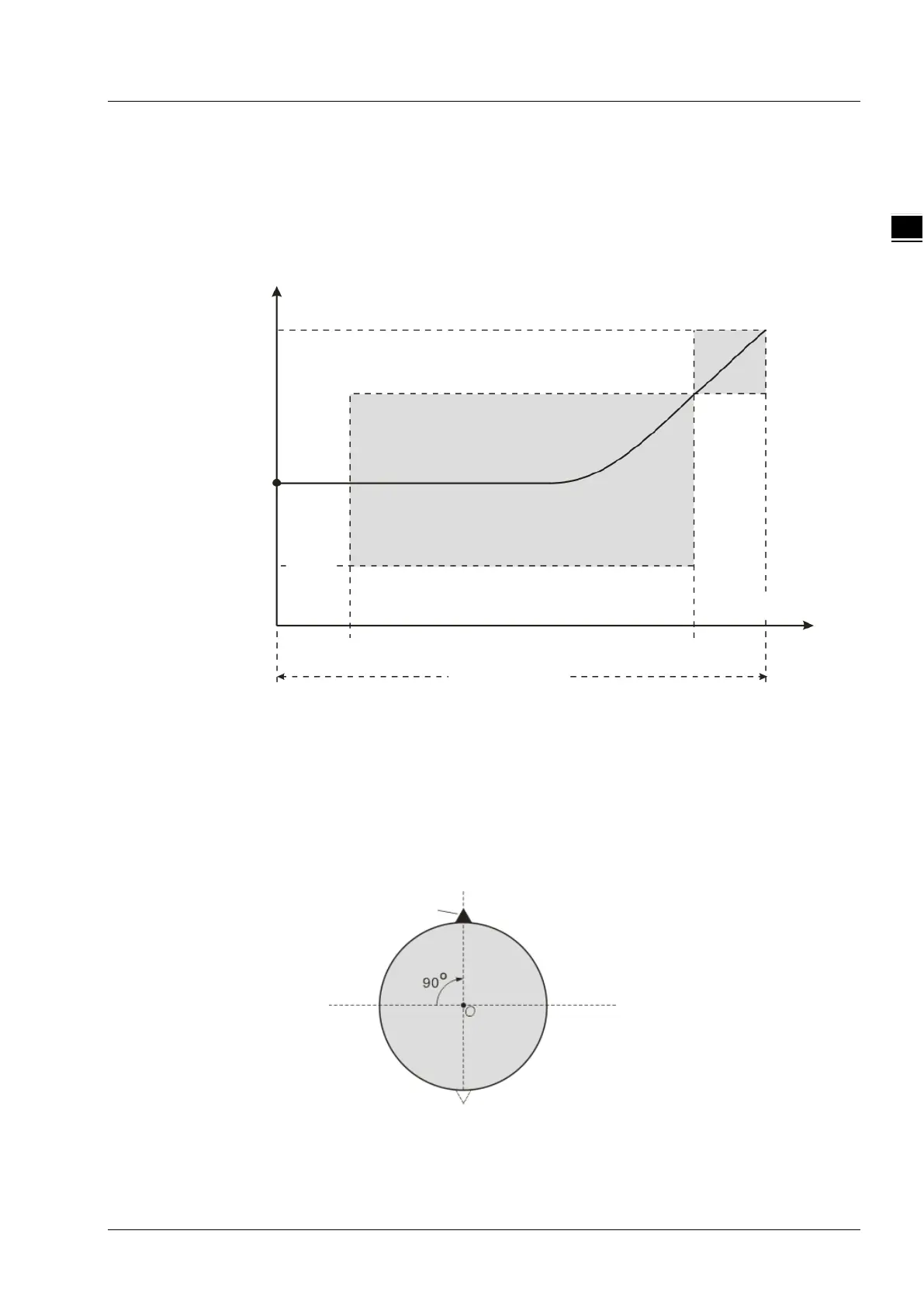

4. The entry curve

It is the rotary cut curve when rotary cut function is started.

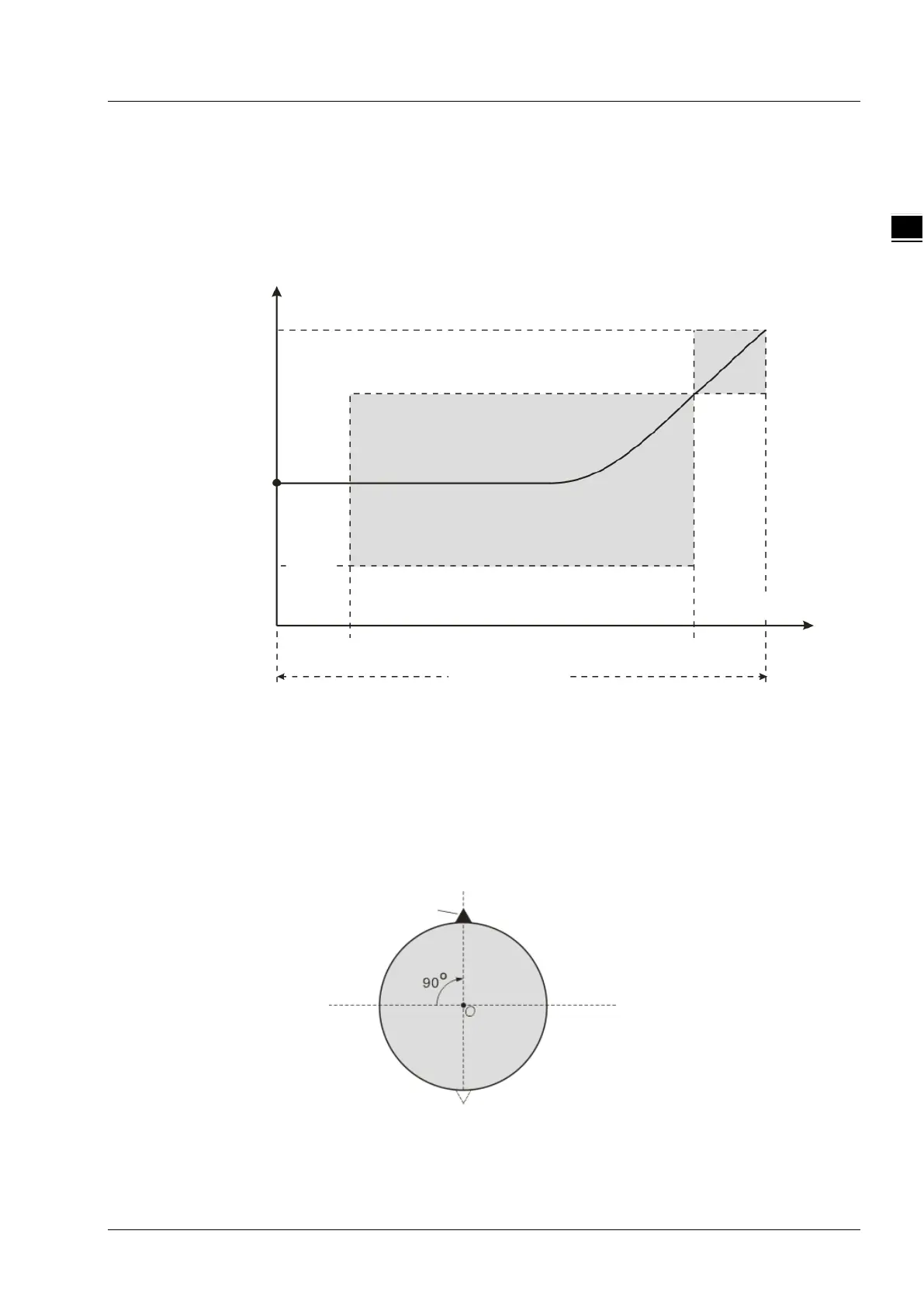

The curve is the rotary cut function entry curve. When the rotary cut function is started up, the rotary cut

axis will follow the feed axis to rotate according to the curve. The entry position is based on the rotary

cut axis. For the single knife, the cutting position is directly below the rotary cut roller if the entry position

is over the rotary cut roller in the following figure. Before the rotary cut function is started up, the knife

must be turned to the upper of the rotary roller. Otherwise, the cutting may happen in the adjustment

area.

area

position

Loading...

Loading...