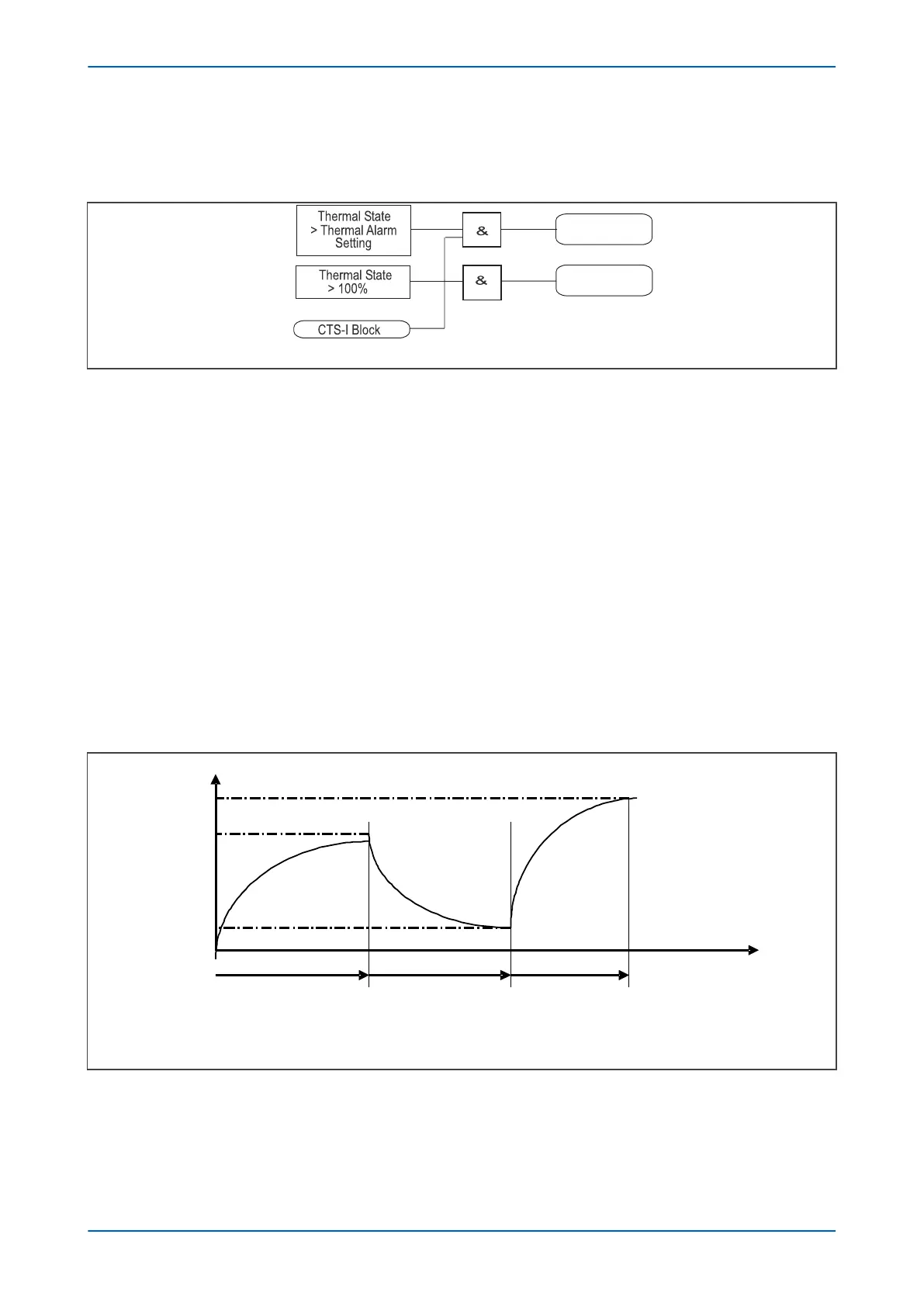

The DDB signal Thermal T

rip indicates tripping of the element . A further DDB signal Thermal Alarm is generated

from the thermal alarm stage. The state of the DDB signal can be programmed to be viewed in the Monitor Bit x

cells of the COMMISSION TESTS column in the relay.

E00776

Gen

Thermal Alarm

Gen

Thermal Trip

P1629ENd

Figure 17: Thermal overload protection logic diagram

Thermal lock

out

This function compares the thermal capacity available with the lockout setting immediately after a trip, for

example when the interrupting device is open. If the thermal capacity available is insufficient to allow restart, an

output contact programmed for the lockout function (Thermal Lockout) is energized, which inhibits a restart.

When the motor has cooled down, this function resets the lockout output contact.

The thermal lockout drops off at 97% of the thermal lockout threshold.

The estimated time to next start is the time to reach the thermal lockout threshold. This is in the MEASUREMENTS 3

menu and is given by the following formula:

T = T

r

* Ln (q

1

/q

2

)

Where:

T

r

= cooling time constant,

q

1

= initial thermal state,

q

2

= final thermal state = 97% of thermal lockout threshold.

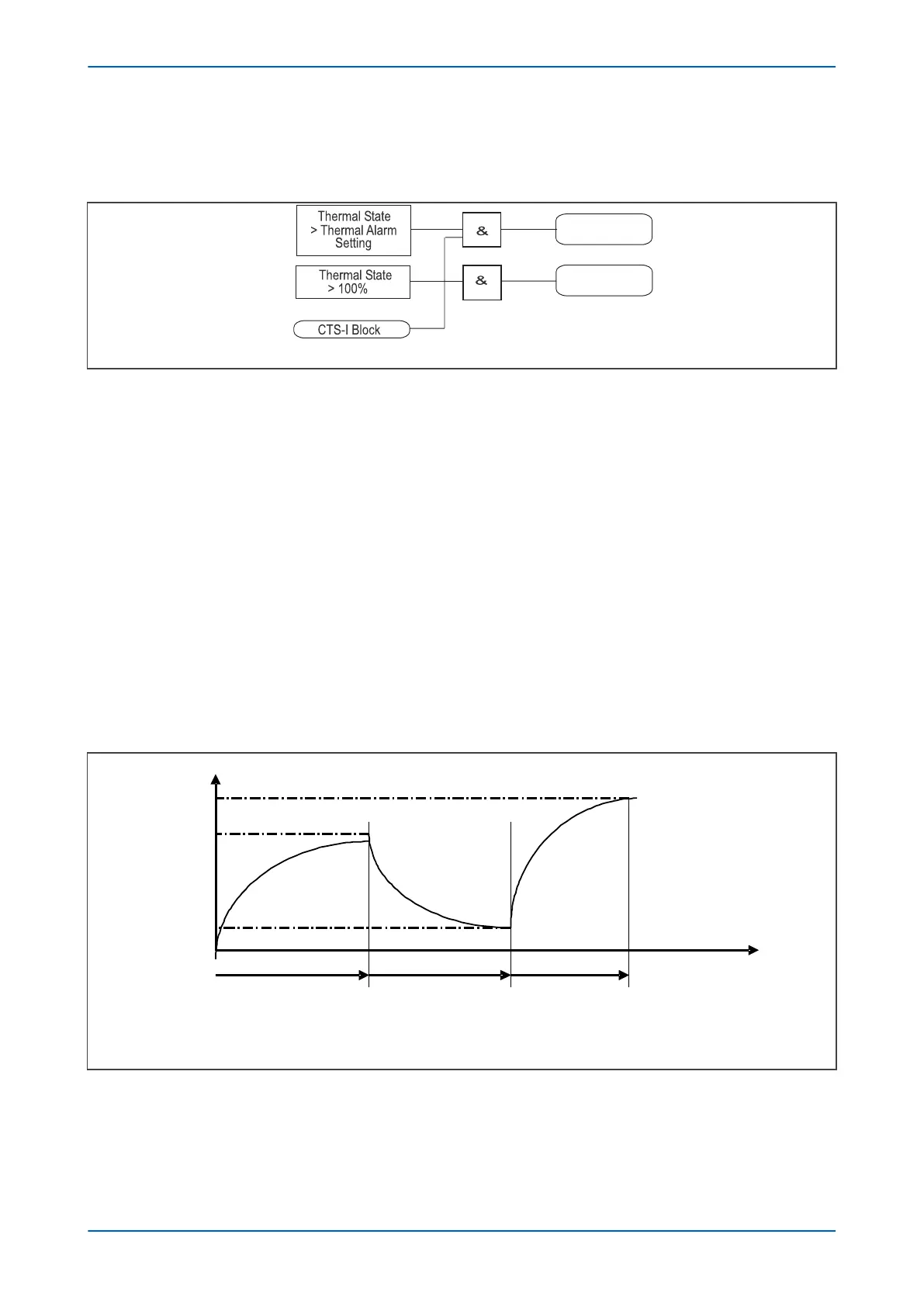

Thermal State

Time

T1 T2 T3

20 %

80 %

100 %

P0658ENa

Figure 18: Cooling time constant

P24xM Chapter 6 - Current Protection Functions

P24xM-TM-EN-2.1 77

Loading...

Loading...