Emergency restart

Cir

cumstances may dictate the necessity to restart a hot motor. An emergency restart can be enabled via an opto

input (Emergency Rest.), via the user interface, or via the remote communications. This feature effectively removes

all start inhibits (Thermal Lockout, Hot start Nb, Cold start Nb, and Time betwe start).

This feature will reset the thermal memory to 90% if it is greater than 90% or stays as it is if less than 90%.

When an emergency restart is required, the inhibition of thermal curve during start-up will be active, even if this

function is not used during a start-up in normal operation.

2.4 USER PROGRAMMABLE CURVE FOR THERMAL OVERLOAD PROTECTION

For information on how to program a customised thermal overload curve and send and extract curves to and

fr

om the relay, refer to the MiCOM S1 Agile Settings Application Software user guide.

Note:

If a user programmable curve is enabled in the Thermal Overload protection, the thermal state remains at 0% for as long as

I

eq

is less than I

th

. Therefore the number of hot starts and cold starts should not be used.

Note:

If Data P

oints rather than a Formula are used to configure a customised curve, data entered in the Time column can be in

scientific format and the maximum time allowed by the tool is 1E+308.

2.5 APPLICATION NOTES

2.5.1 THERMAL OVERLOAD SETTING GUIDELINES

2.5.1.1 THERMAL SETTING ITH

The Ith Curr

ent Set setting chosen depends on the type of motor being protected. Most machines are termed CMR

(continuous maximum rating) motors. These motors are designed to carry the nameplate value or full load current

continuously. A CMR motor can be run at a value less than its CMR and set to trip at its CMR.

Alternatively, if the machine is not a CMR motor, then the I

th

setting needs to take into account the amount of

overload, which can be tolerated without resulting in thermal damage. A typical allowable overload can be in the

region of 10% of rated temperature. It is important to realize that the temperature build up in the machine is

approximately equal to the current squared. Therefore a 10% temperature overload is equivalent to a 5% current

overload.

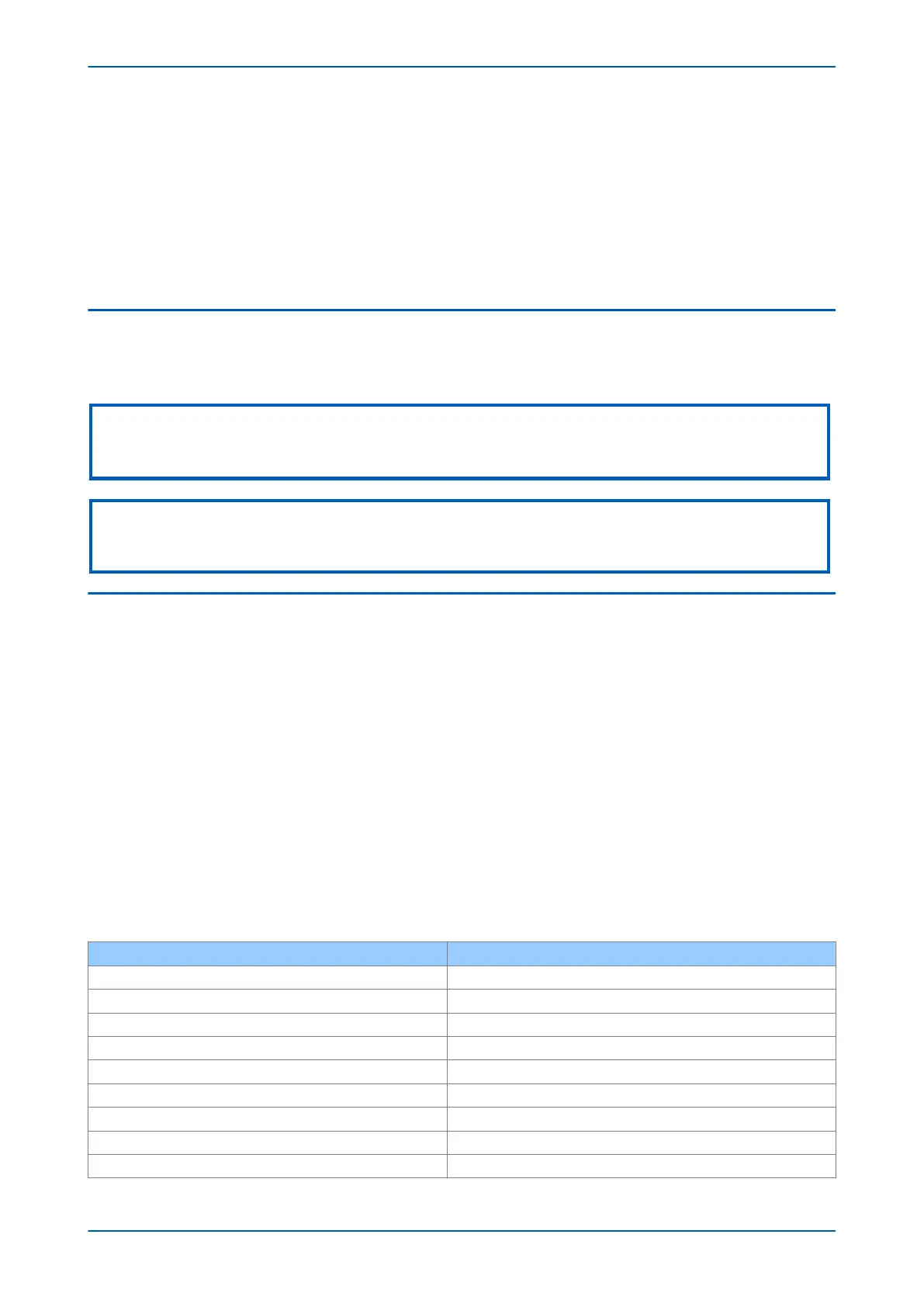

Setting example:

The following motor parameters are used to show how to determine the P24xM settings.

Voltage 11 kV

Full load current 293 A

Starting current 470 %

Starting time 10 s

Heating time constant 20 min

Cooling time constant 100 min

Hot locked rotor withstand time 20 s

Cold locked rotor withstand time 30 s

CT Ratio 300 / 1

VT Ratio 11.5 kV / 110 V

Chapter 6 - Current Protection Functions P24xM

78 P24xM-TM-EN-2.1

Loading...

Loading...