D1-N Series Servo Drive User Manual Modbus Communication

14-6 HIWIN MIKROSYSTEM Corp.

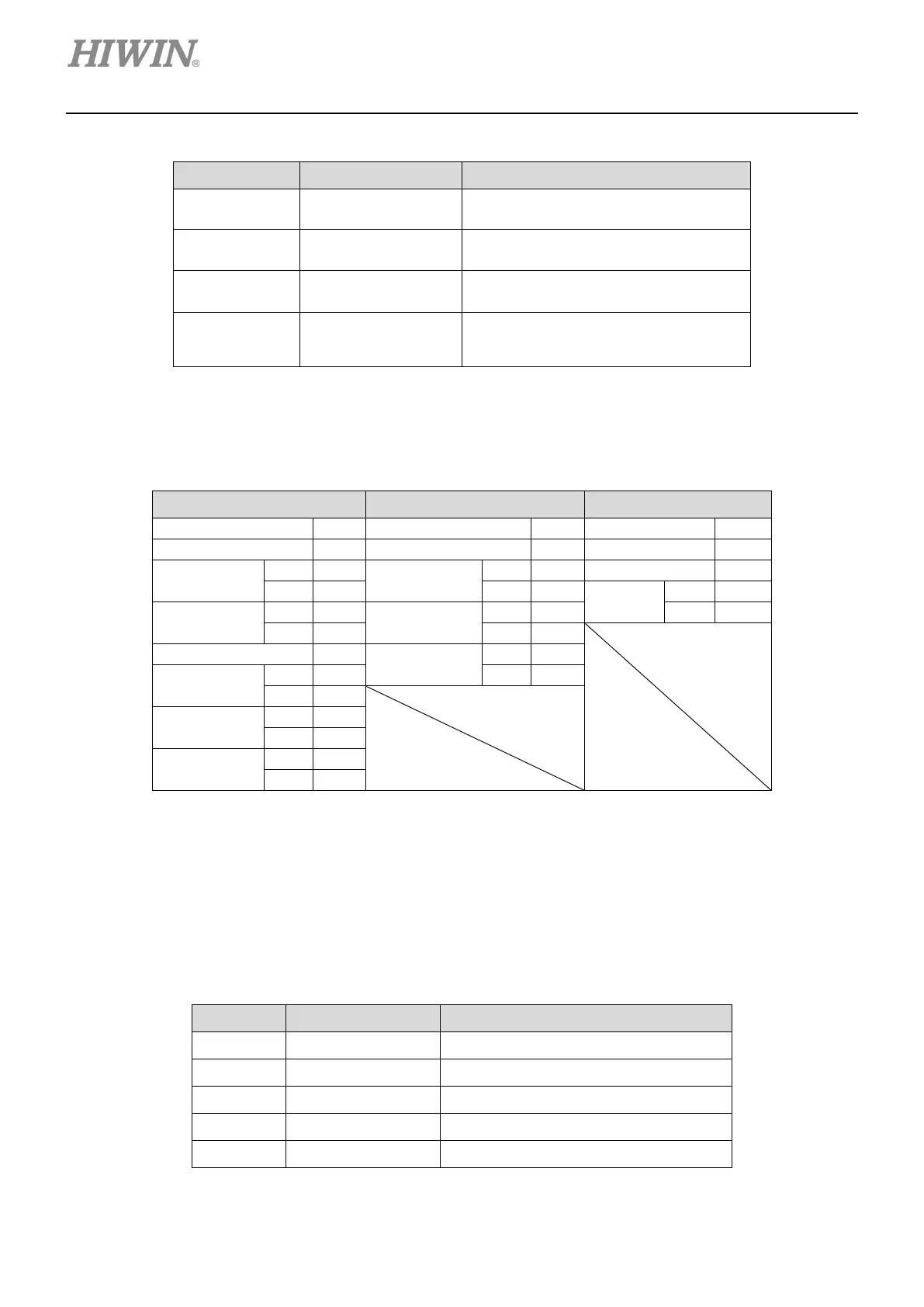

Table14.2.9

Exception Code Definition Description

01h Illegal function The function code is not supported.

02h Illegal data address Try to read an illegal register.

03h Illegal data value The number of registers is over 123.

04h Servo device failure

The request contains incomplete data.

For instance, the controller only

requests 16 bits of a 32-bit parameter.

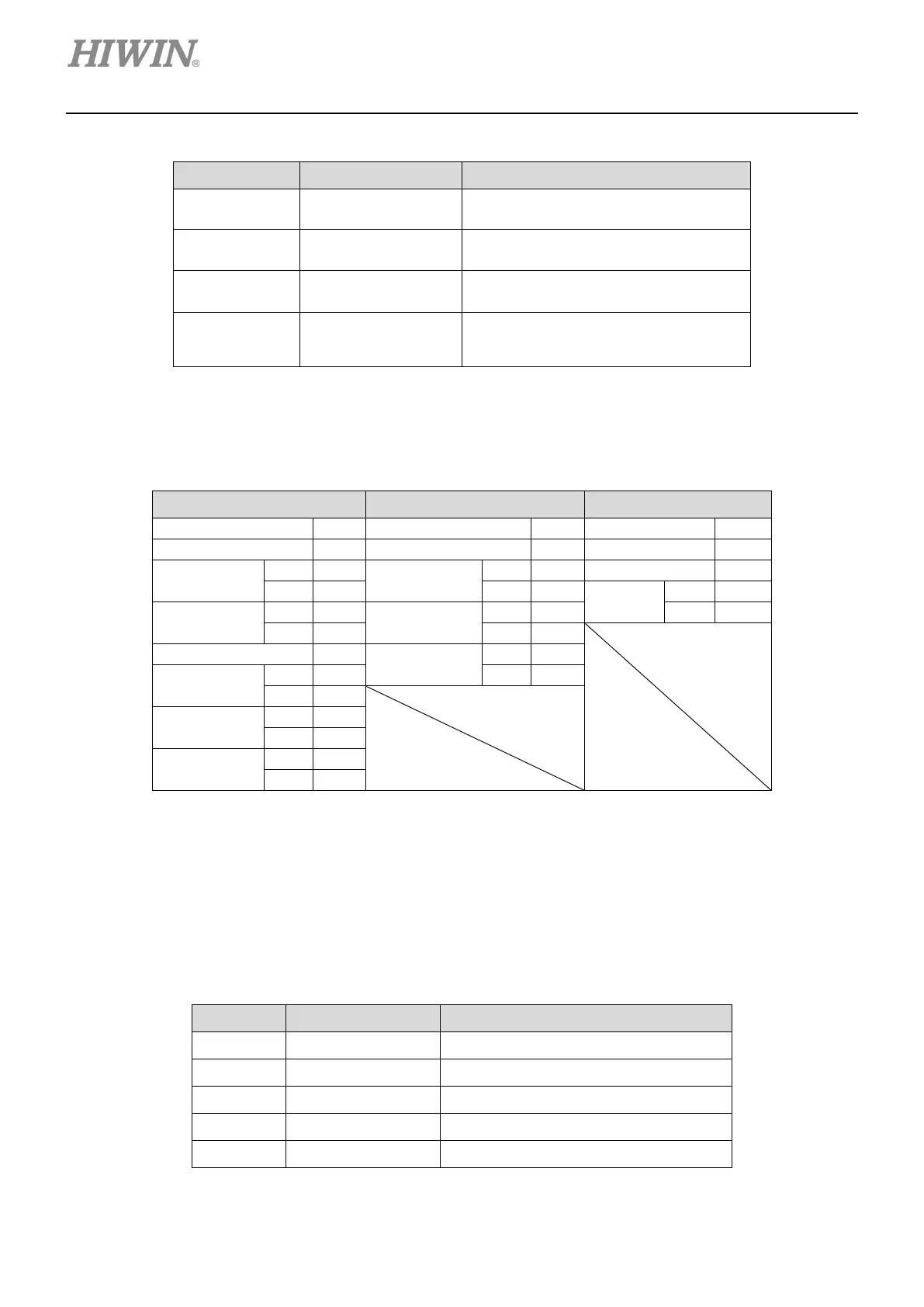

Table 14.2.10 is the example of writing two registers. The starting address is 0x0001. The values are

00 0Ah and 01 02h.

Table14.2.10

Command Response Error

Starting

address

Starting

address

CRC

Register

number

Register

number

CRC

Register

0x0001

Register

0x0002

CRC

14.3 Modbus object

The data types of Modbus objects are listed in table 14.3.1.

Table14.3.1

Code Data Type Data Range

INT16 Signed 16 bit -32,768~+32,767

INT32 Signed 32 bit -2,147,483,648~+2,147,483,647

UINT16 Unsigned 16 bit 0~65,535

UINT32 Unsigned 32 bit 0~4,294,967,295

REAL32 Float 32 bit -

Loading...

Loading...