D1-N Series Servo Drive User Manual Protection Function

8-6 HIWIN MIKROSYSTEM Corp.

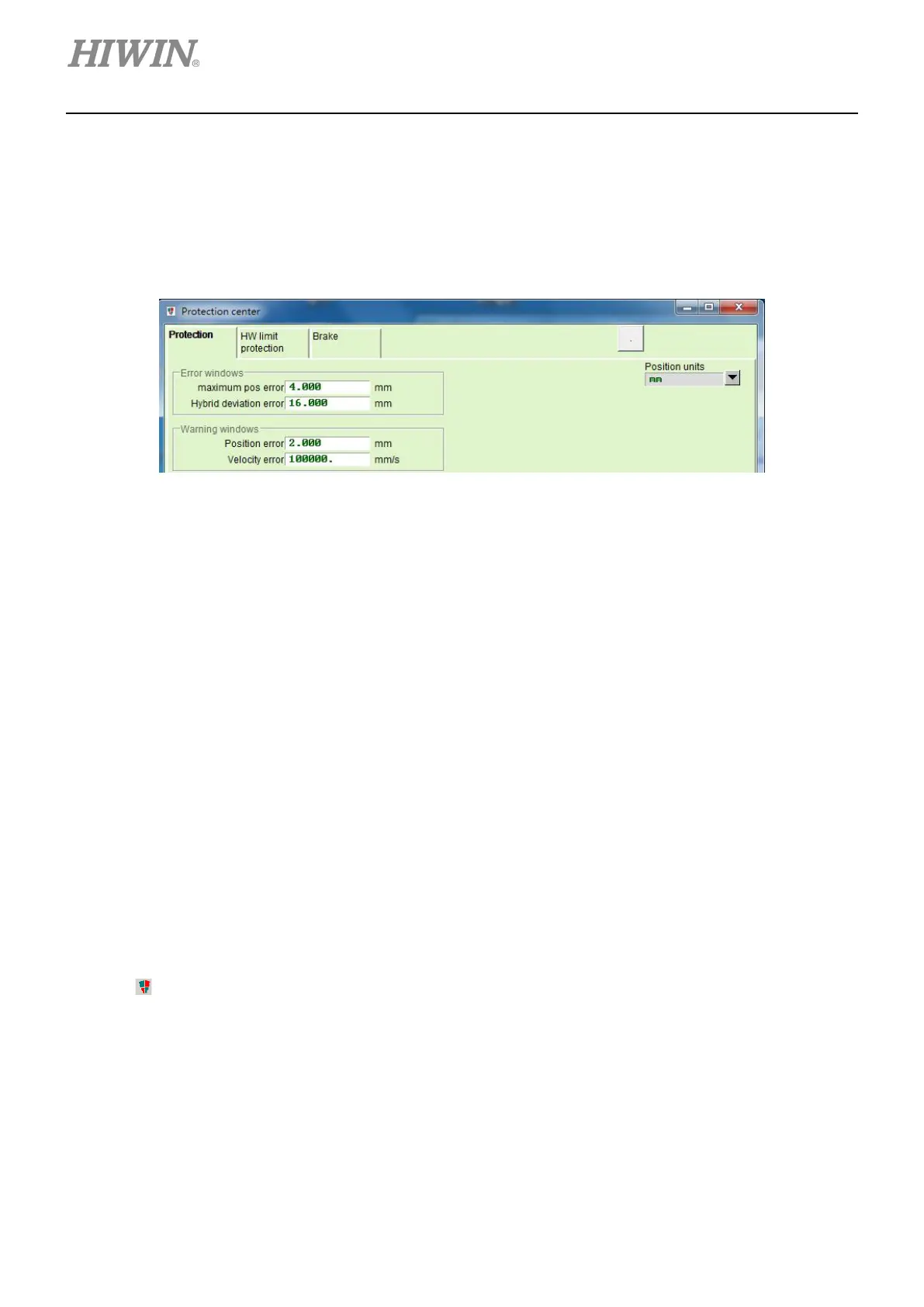

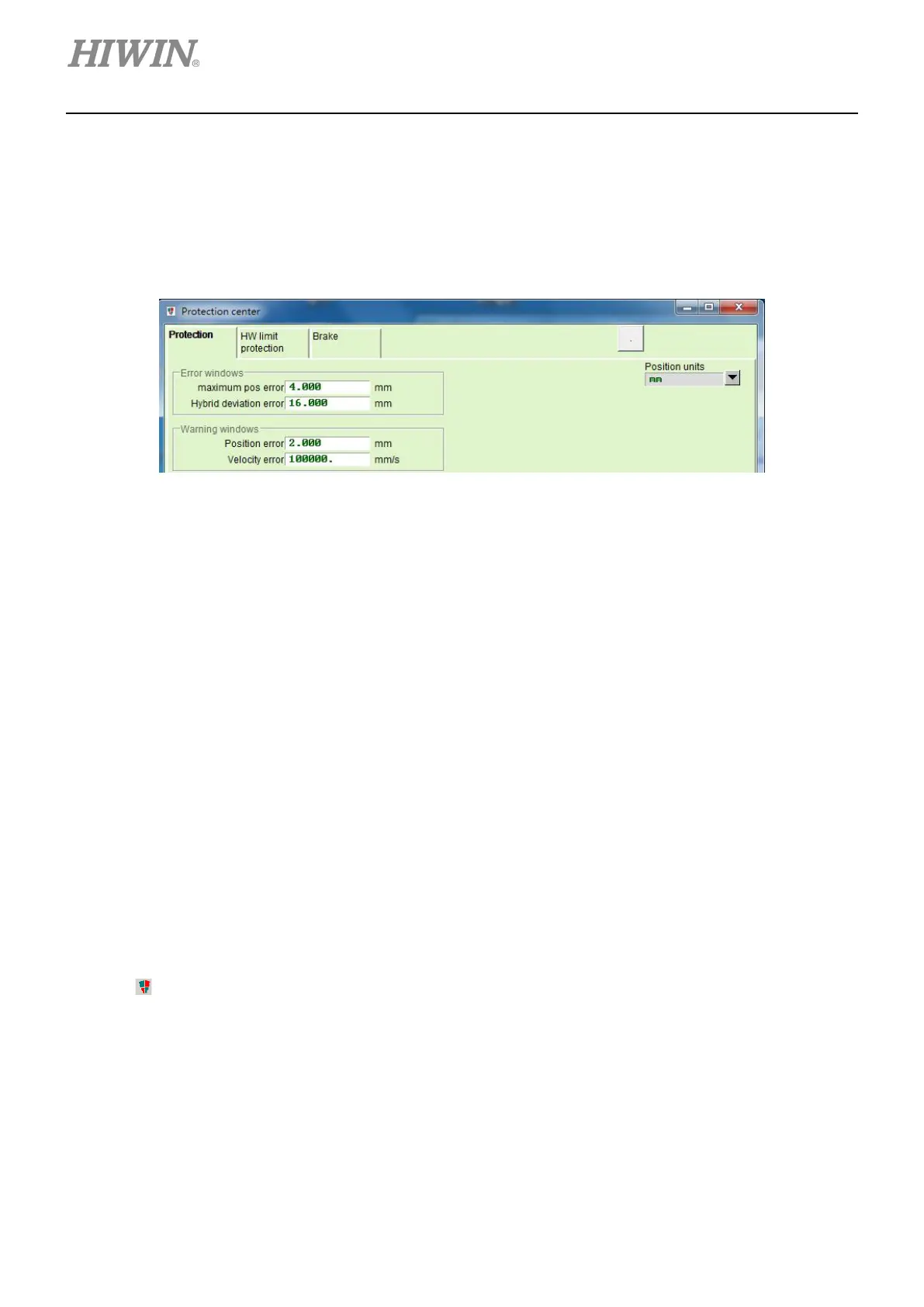

When using models which support dual loop control, users are allowed to set hybrid deviation error in

Protection tab of Protection center to prevent excessive error from causing unstable velocity loop or

position loop. When error exceeds the setting value of hybrid deviation error, error “Hybrid deviation too

big” occurs. If dual loop control is not used, the field of Hybrid deviation error is greyed out and cannot

be set.

Figure 8.2.1.2

8.2.2 Position error warning and velocity error warning

In addition to the position error limit described in section 8.2.1, D1-N servo drive also provides warning

function. When position error or velocity error exceeds the setting in Warning windows, a warning

message will appear in the main window of Lightening to inform users.

8.3 Brake protection

D1-N servo drive supports brake signal output to enable electromagnetic brake to protect motor and

mechanism. This is often used for motor of Z axis. The timing of enabling brake is essential in such

application. When motor moves in Z direction at high speed and the servo drive receives disabling

command and commands the brake to engage directly, a huge vibration may occur and cause damage to

the mechanism. If the motor is disabled too early, the motor and mechanism may possibly slip. Therefore,

D1-N servo drive provides brake parameters to avoid the above situations.

Click on

to go to Protection center. Click on Brake tab to open the setting page for timing diagram of

brake engagement. Click on Set… button to open the setting window of I/O center to set the output pin of

brake signal. The default setting is O4. For setting method of digital output, please refer to section 5.4.2.

When the servo drive receives the disabling command from hardware or software, it will start the following

procedures.

Loading...

Loading...