JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 103

6.4 Gear Mode

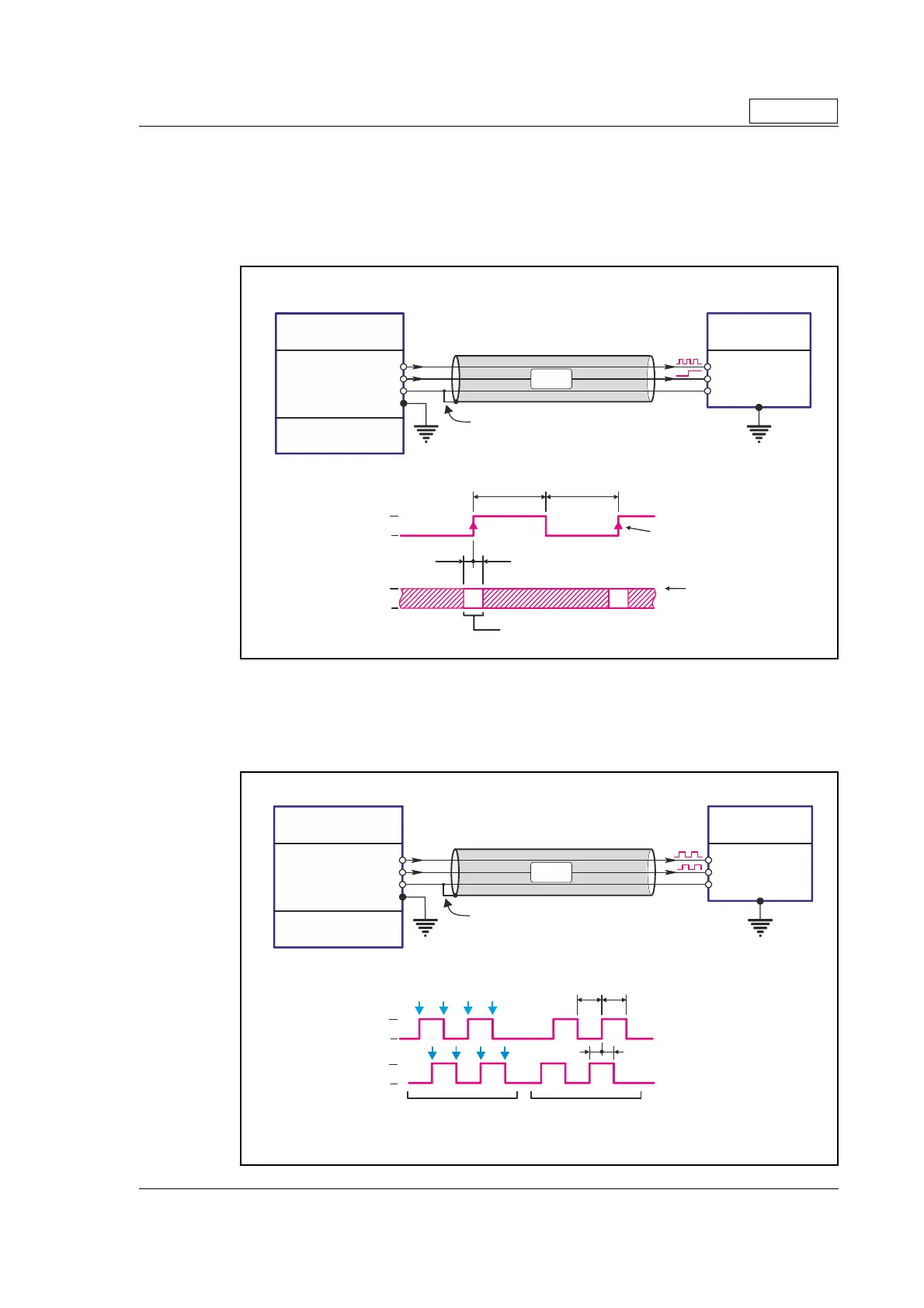

6.4.6 Signal function and timing (only MIS23x).

The description below shows how to connect the pulse source when using the pulse and

direction format. Also the timing is shown. Please be aware that if the indicated minimum

timing is not respected the motor may loose some of the step clocks and the position of

the motor will end up being out of synchronism with the pulse generator.

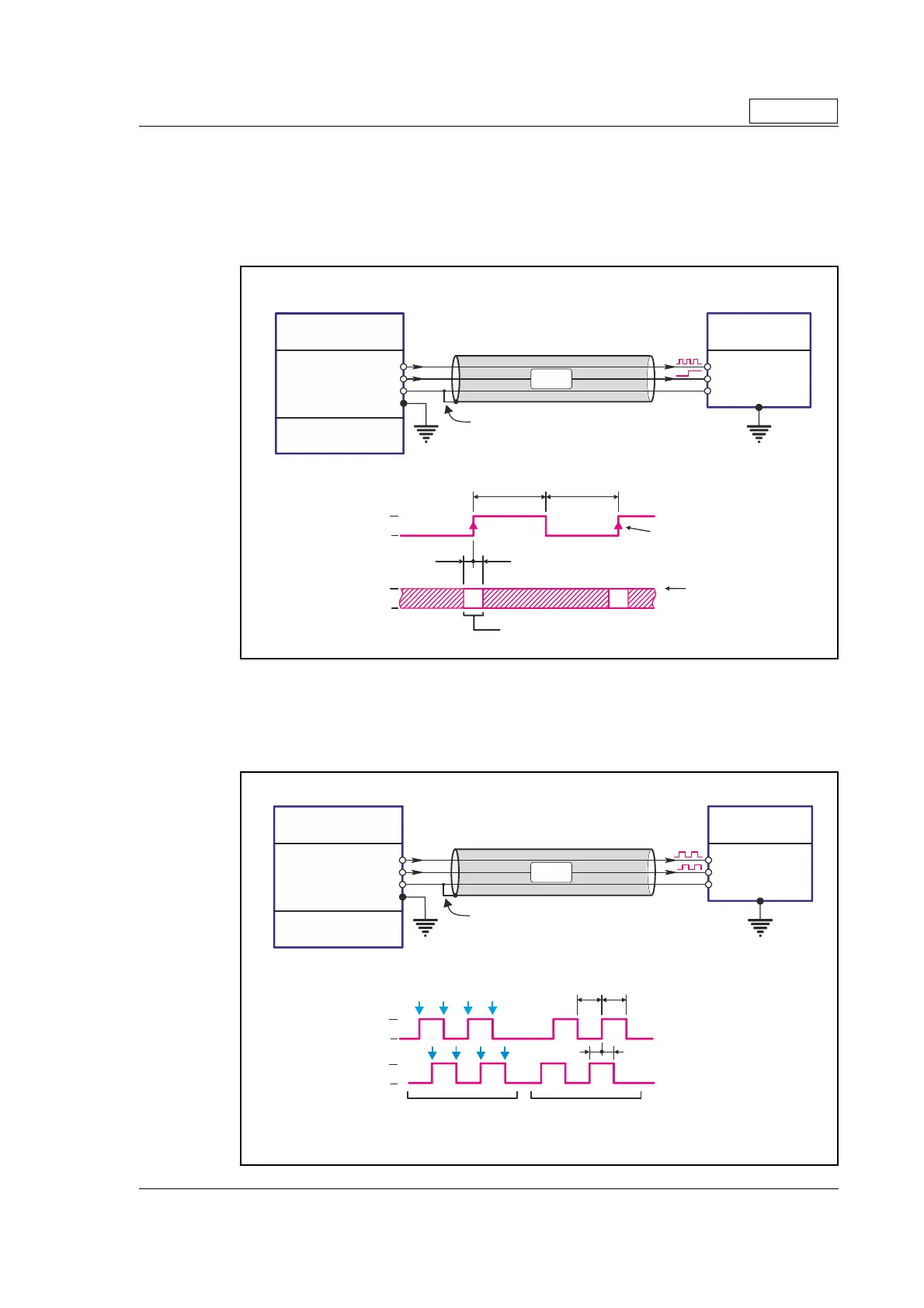

The description below shows how to connect the pulse source when using the quadra-

ture format. Also the timing is shown. Please be aware that if the indicated minimum tim-

ing is not respected the motor may loose some of the step clocks and the position of the

motor will end up being out of synchronism with the pulse generator.

Only MIS23x

TT2172GB

Note ! : screen only

connected on signal source.

MIS23x

or SMC75

Screen

Step clock (IO1)

Direction (IO2)

Pulse and direction format - Timing and how to connect

Min. 5µS

Min. 2.5µSMin. 2.5µS

The Direction signal must stay stable and well defined

in the indicated period while the clock has a risin

ed

e.

Step occurs on the

leading flank

Motor moves CW when

direction is high (1) and

CCW when low (0).

Min. 5µS

IO2

IO1

GND

1

1

0

0

Step clock Output

PLC or Pulse

Generator

PNP (source) or

Push-Pull outputs

Direction Output

Ground

EE

Level definitions

Logic 0" = < 1.0V

Logic 1" = > 2.8V

"

"

TT24

4-

1

B

Note ! : screen only

connected on signal source.

MIS23x

or SMC75

Screen

Channel A (IO1)

Channel B (IO2)

Quadrature format - Timing and how to connect

Min. 2µS

Min. 2µS

Step occurs on each

transition on either

the A or B channel

Min.

5µS

Min.

5µS

IO2

IO1

GND

1

1

0

0

Channel A Output

Incr. Encoder

or other source

PNP (source) or

Push-Pull outputs

Channel B Output

Ground

E

E

Ch. A is 90 degree

ahead which will

cause the motor

to move

CW

Ch. B is 90 degree

ahead which will

cause the motor

to move

CCW

Level definitions

Logic 0" = < 1.0V

Logic 1" = > 2.8V

"

"

Loading...

Loading...