JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x 107

6.4 Gear Mode

Example 1: Encoder (quadrature) input.

An external encoder feeds the MIS. The I/O type is set to “Pulse in-

put“ and “Input type” is set to “Quadrature” in order to decode the

encoder signal. The encoder is connected to the 2 pulse input termi

-

nals. See also How to connect the pulse source., page 101.

The resolution of the external encoder is 500 ppr. The MIS motor it-

self has 1600cpr (MIS23x) or 409600 cpr (MIS34x and MIS43x). If this

application requires that the MIS motor rotates 1 rev. each time the

external encoder has rotated 1 rev., the Input parameter is set to 500

(external encoder) and the Output parameter is set to 1600

(MIS23x)or 409600 (MIS34x or MIS43x).

Now the ratio between the external encoder and the MIS motor will

be 1:1. Ensure the “Profile data” is set to proper values in order not

to limit motor operation unintentionally.

Example 2: Pulse and direction input.

A traditional step motor system with separate driver and motor is re-

placed by the integrated MIS motor, meaning that the MIS motor re-

ceives a pulse and direction signal which is a very common signal

format in step motor applications.

The I/O type is set to “Pulse input“ and “Input type” is set to “Pulse-

direction” in order to decode the input signal. The pulse signal is con

-

nected to the 2 pulse input terminals. See also How to connect the

pulse source., page 101.

The MAC motor is replacing a step motor system with 400 steps per

revolution, which means that when the pulse source produce 400

pulses, it expects the MIS motor to rotate one revolution.

The MIS motor itself has 1600cpr (MIS23x) or 409600 cpr (MIS34x

and MIS43x). If this application requires that the MIS motor rotates 1

revolution each time 400 pulses are received, the Input parameter is

set to 400 since the MIS motor interpret every rising edge at the ap

-

plied pulse signal as one count (step).

The Output parameter is set to 1600 (MIS23x) or 409600 (MIS34x or

43x) since this is the number of counts (steps) on one revolution.

Now the MIS motor will move 1 revolution for every 400 pulses that

are applied to the pulse input. Ensure the “Profile data” is set to prop

-

per values in order not to limit motor operation unintentionally.

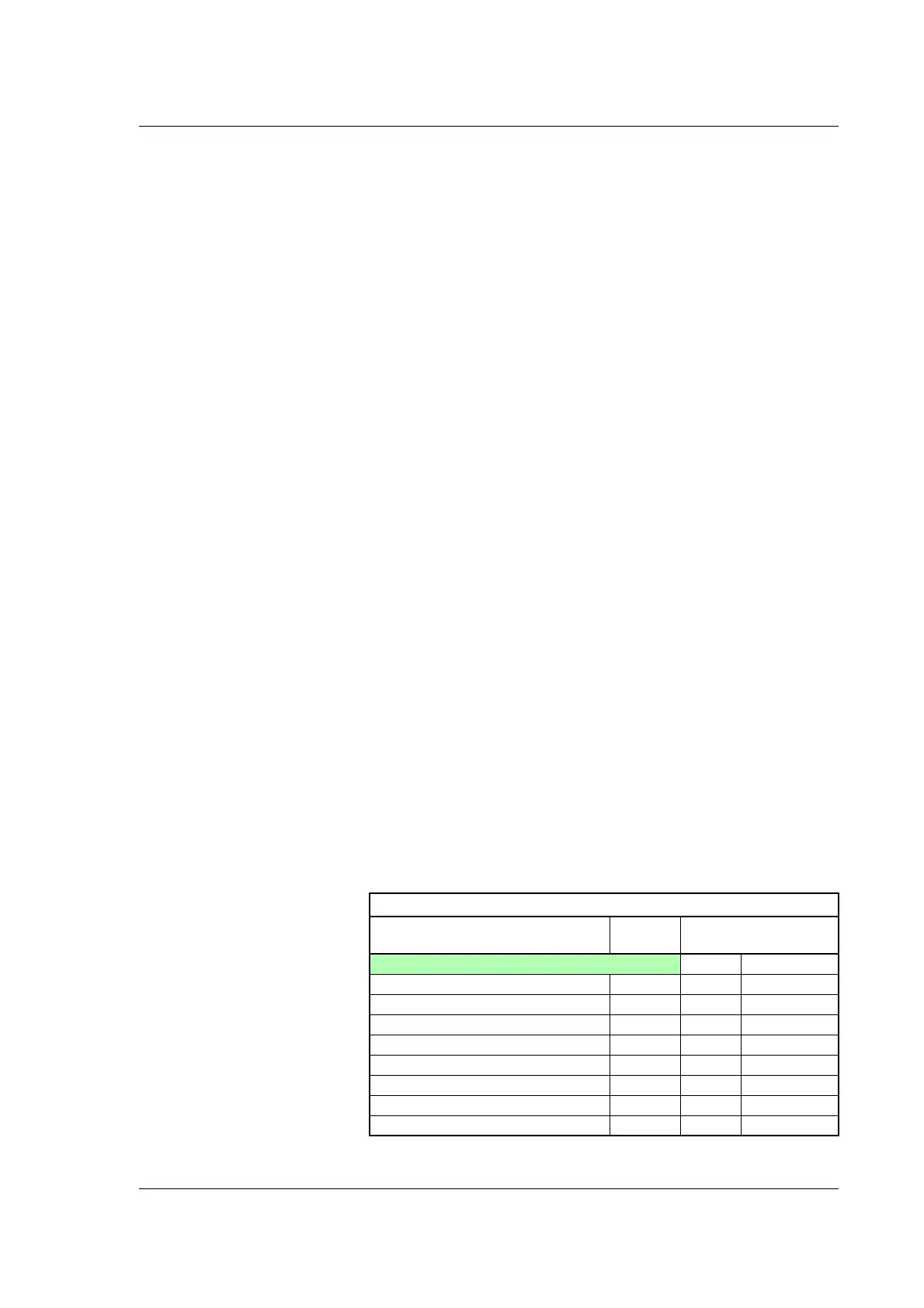

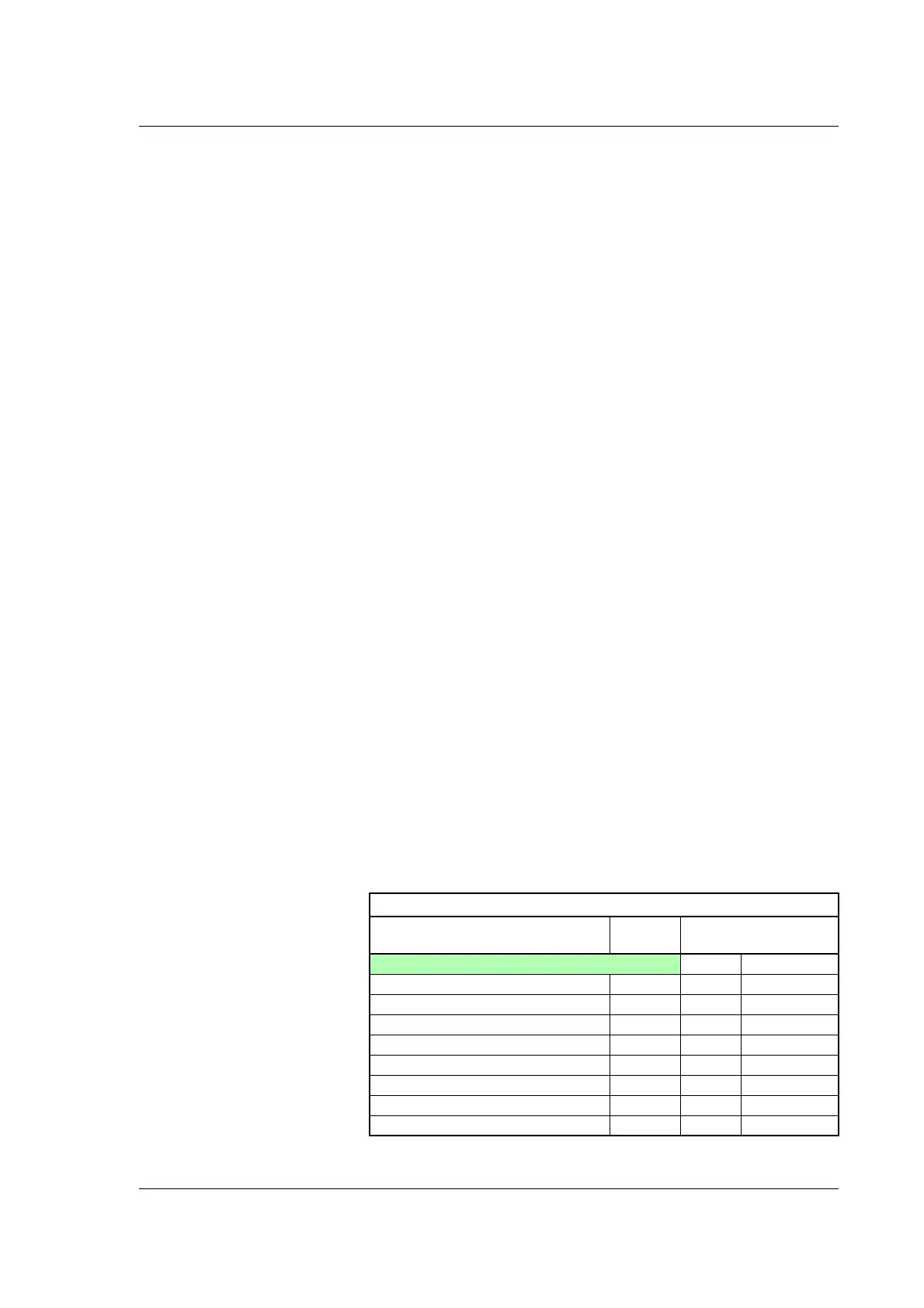

The following table can be used as guide for setting up typical gear ra

tios:

Pulse and direction gear ratio setup - “Commonly used ratios”

Applied number of pulses(clocks)

per desired MIS motor revolution.

“Input”

register

“Output”

register

MIS23x MIS34x or 43x

200 200 1600 409600

400 400 1600 409600

500 500 1600 409600

800 800 1600 409600

1000 1000 1600 409600

1600 (Equal to the MIS23x resolution) 1600 1600 409600

2000 2000 1600 409600

409600 (Equal to the MIS34x/43x resolution) 409600 1600 409600

Loading...

Loading...