106 JVL Industri Elektronik A/S - User Manual - Integrated Stepper Motors MIS23x, 34x, 43x

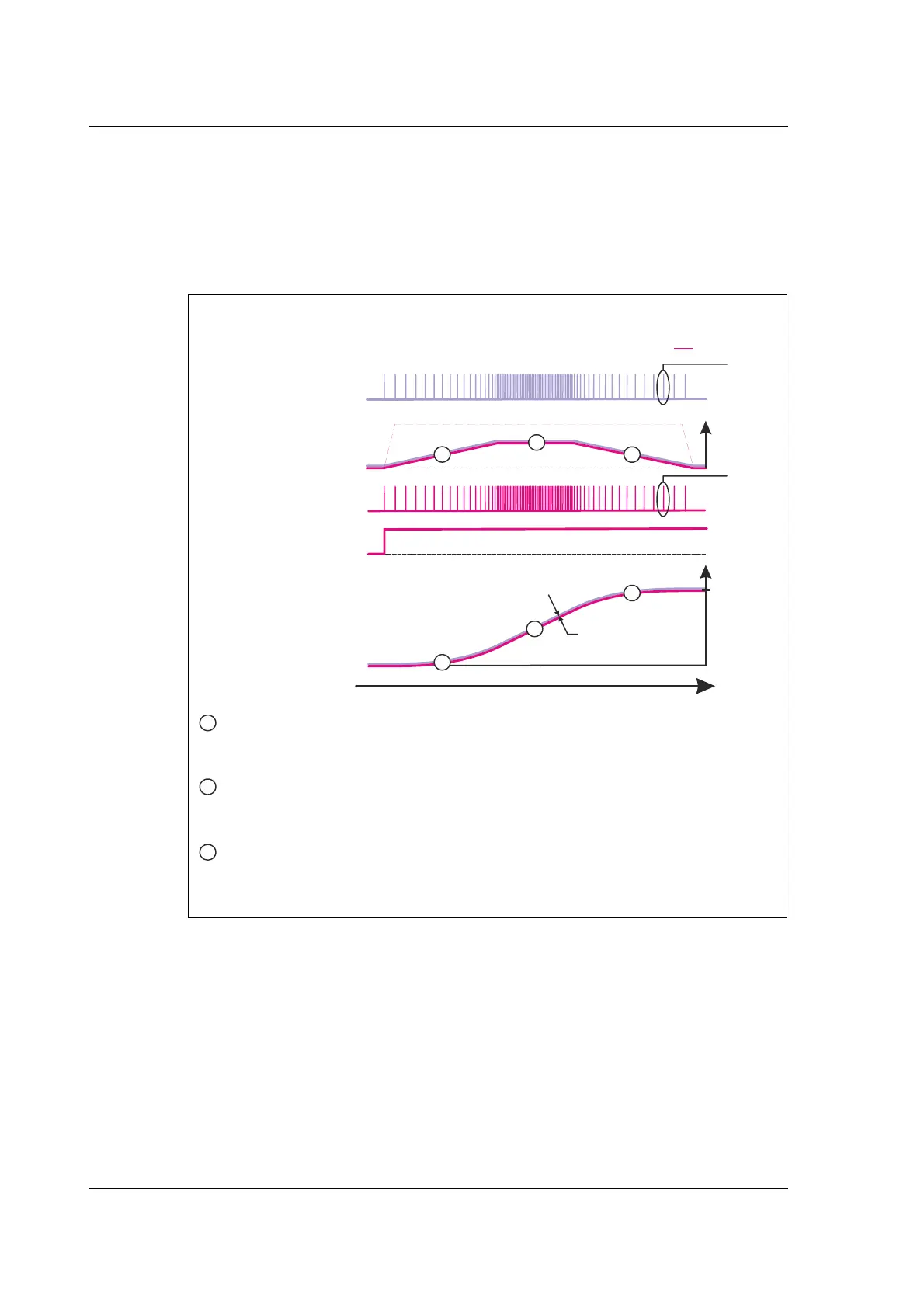

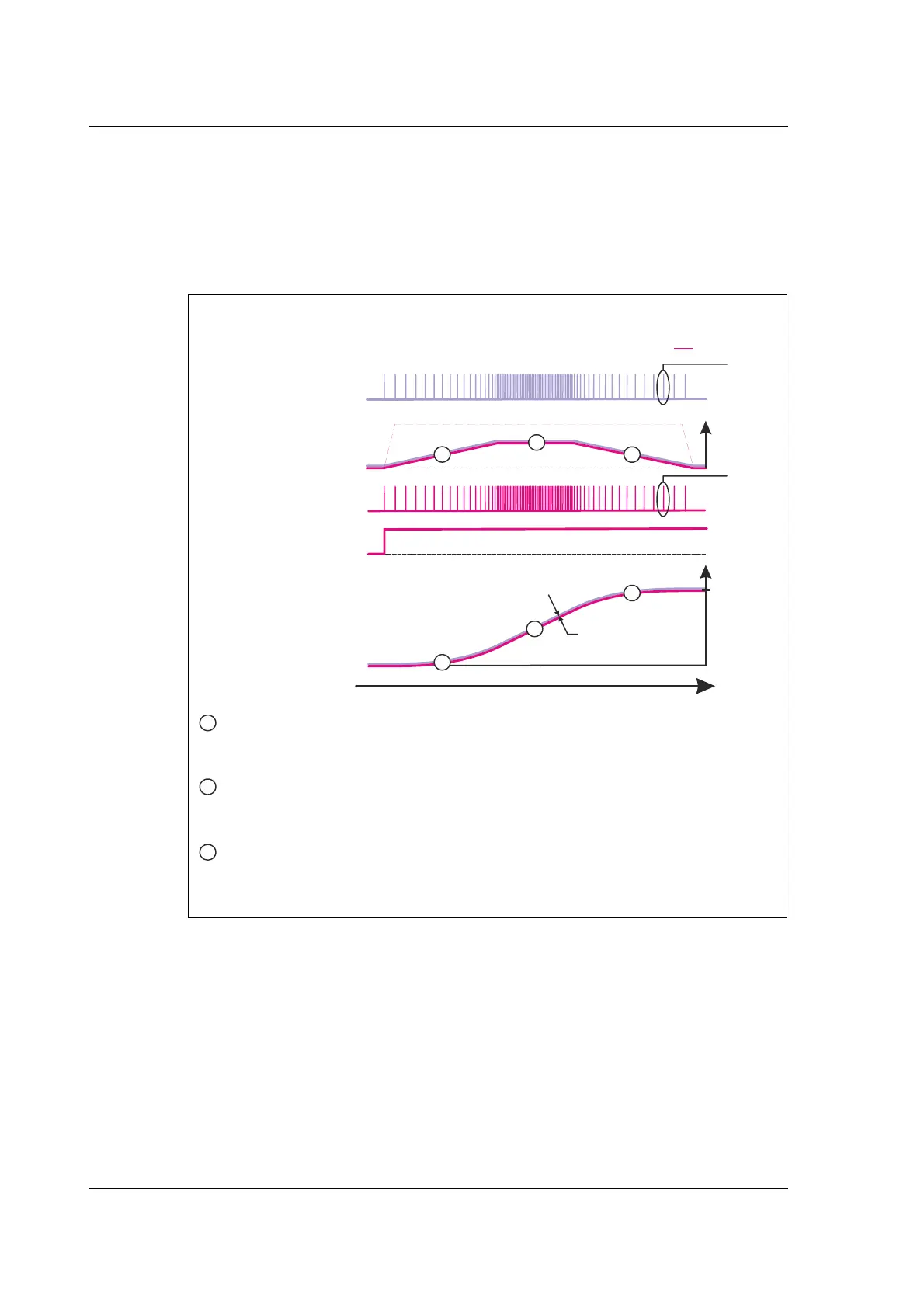

6.4 Gear Mode

As an alternative to the previous illustration the full control can be done by the master

by setting the velocity and acceleration registers to a significant higher value than the

equivalent value of the clock source which will assure that the motor follows each clock

with a very narrow timing and no delays.

This solution must be used if the master that produces the clocks do generate the full

motion profile with acceleration to a desired top speed and make sure to decelerate and

hit target.

TT24

-

1

B

Motor steps(counts)

In total 80 steps moved

Motor Direction

Motor Velocity

(Slave)

Input position

(Master)

Motor position

(Slave)

Input clock

In total 80 steps received

Time

Positio

Target

1 step

Minimum

position error

The master that produce the input clock to the motor takes care of producing

acceleration. Since the acceleration register in the motor is set to a high value

it will not limit the demanded acceleration.

0

0

CW

CCW

elocity

e

at

on

etween

nput an

t

e motor

e

av

our w

en sett

ng t

e

velocity and acceleration registers to values.

Motion speed and acceleration/deceleration only and .

high

controlled by the master the motornot

1

1

1

2

2

2

3

3

Similar as during acceleration the velocity register have been set to a high

value and do not cause any limitation of what is demanded from the master

producing the input clocks.

Same relation as during acceleration. The motor will reach target (80 counts)

exactly without any overshoot or time delay compared to the master position.

3

Input Velocity

(Master)

1 step

Acc. and vel. envelope = much larger than source

Loading...

Loading...