262334 215 Revision A

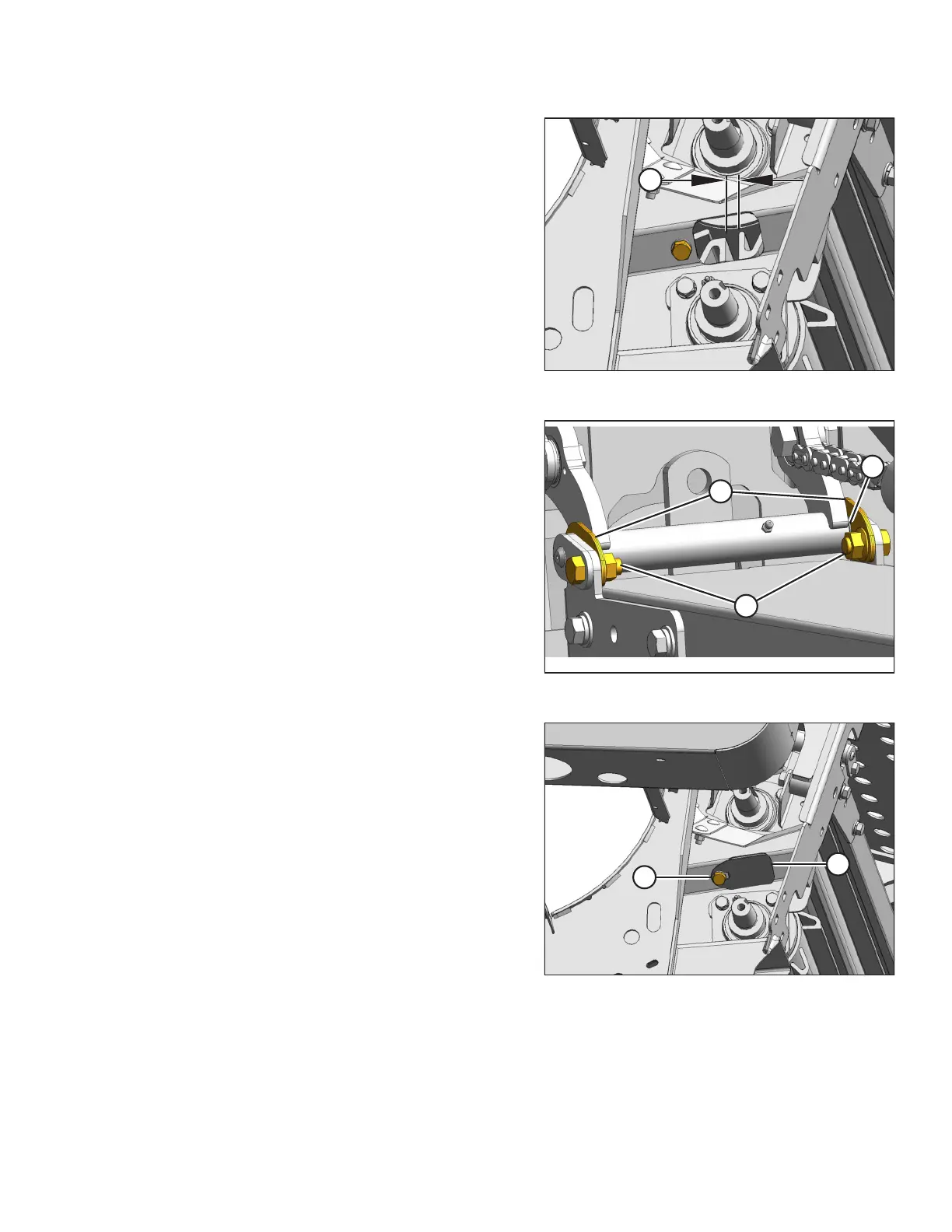

Figure 4.175: Roll Bar Spacing

6. Examine roll bar spacing (X) at each end of the rolls. The

rolls are aligned if (X) varies less than 1.6 mm (1/16 in.)

from one end to the other.

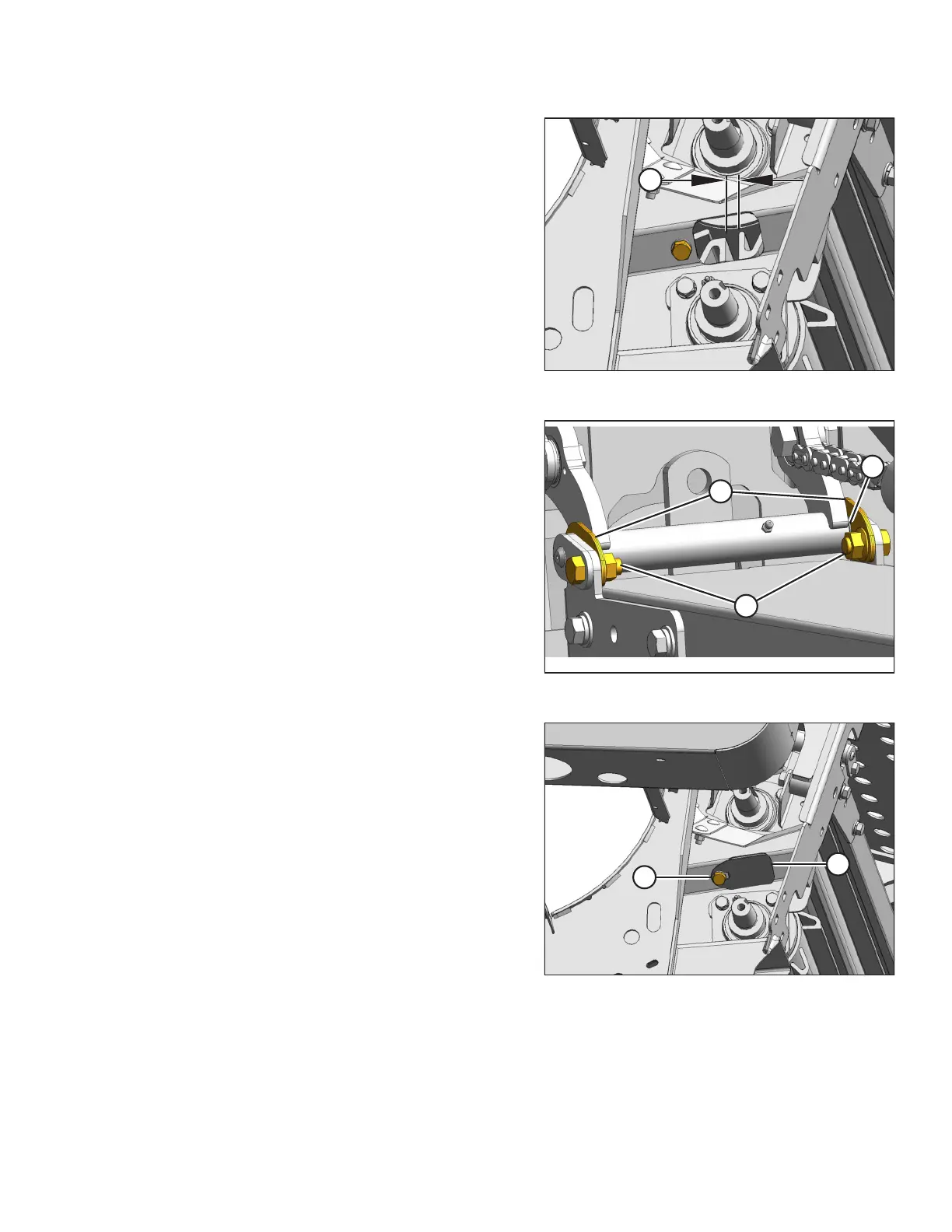

Figure 4.176: Adjustment

7. If roll bar spacing (X) (as shown in Step 6, page 215) varies

more than 1.6 mm (1/16 in.), align the rolls as follows:

a. Remove nuts and bolts (A), and remove shims (B). The

shims can be lifted off the pivot rod.

b. Move the upper roll until dimension (X) at both ends

looking through the port (as shown in Step 6, page

215) is within 1.6 mm (1/16 in.).

c. Reinstall shims, ensuring hardened washer (C) is

against the pivot tube.

d. Reinstall bolts (A) and nuts.

Figure 4.177: Access Cover

8. Operate the header, and recheck the alignment.

9. Close cover (B), and tighten bolt (A).

10. Close the conditioner driveshield.

MAINTENANCE AND SERVICING

Loading...

Loading...