Trainee Guide TR-L2-M2000

Level 2 Maintenance Training – M2000 Dispensing Systems 4-2-30 P/N 73-0018-00 (Revision B)

Information Sheet 4-8-7

DV-7000 Troubleshooting (Continued)

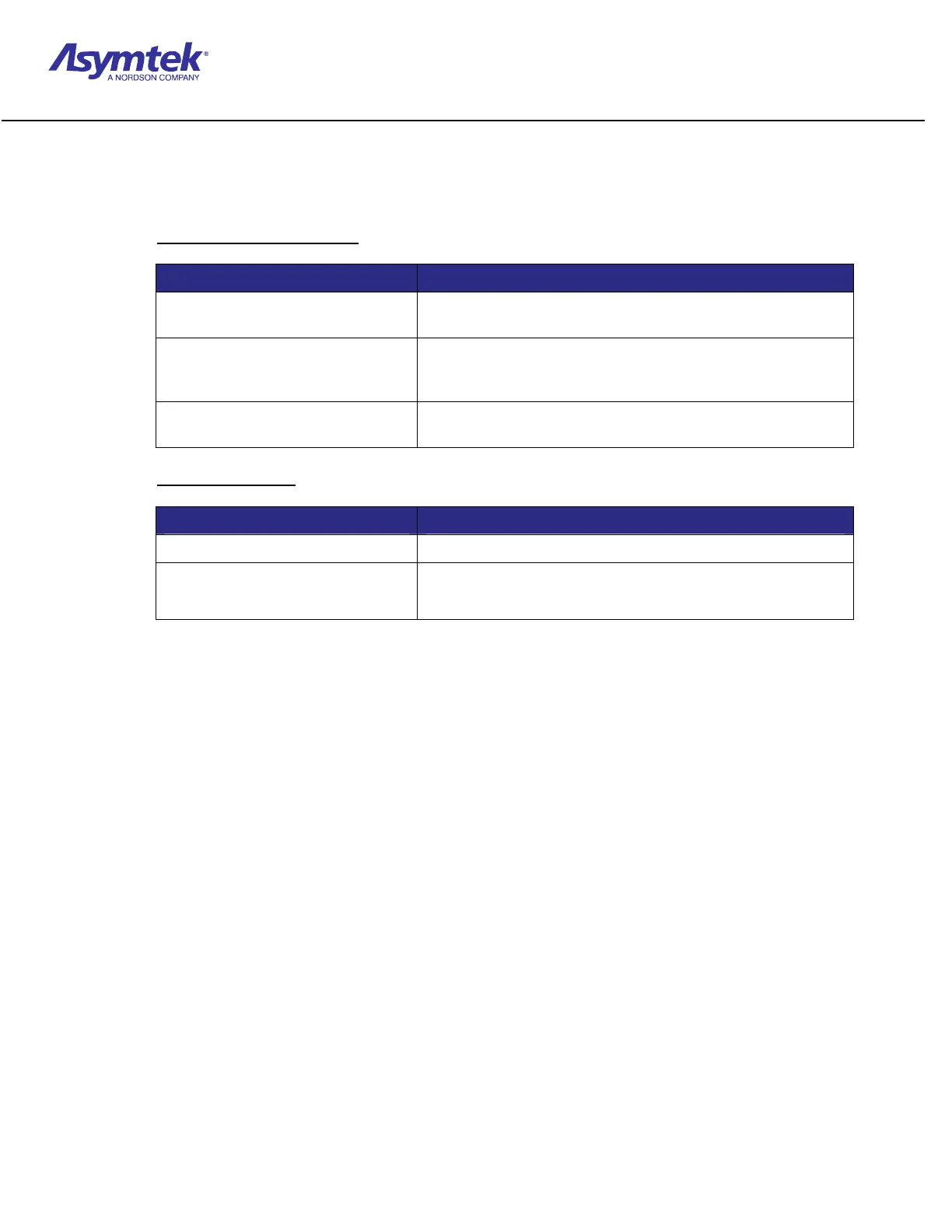

D. Inconsistent Shot Sizes

Possible Cause Recovery

1. Syringe air pressure set too

low

1. Increase syringe air pressure (20 psi max.). Refer to the

system Operations Manual for instructions.

2. Drive mechanics do not have

time to damp-out after X-Y

move

2. Increase the Settling time in the Dot Parameters. Refer

to the FMW or FmNT Online Help for instructions.

3. Feed screw damaged or

binding

3. Call Asymtek Technical Support.

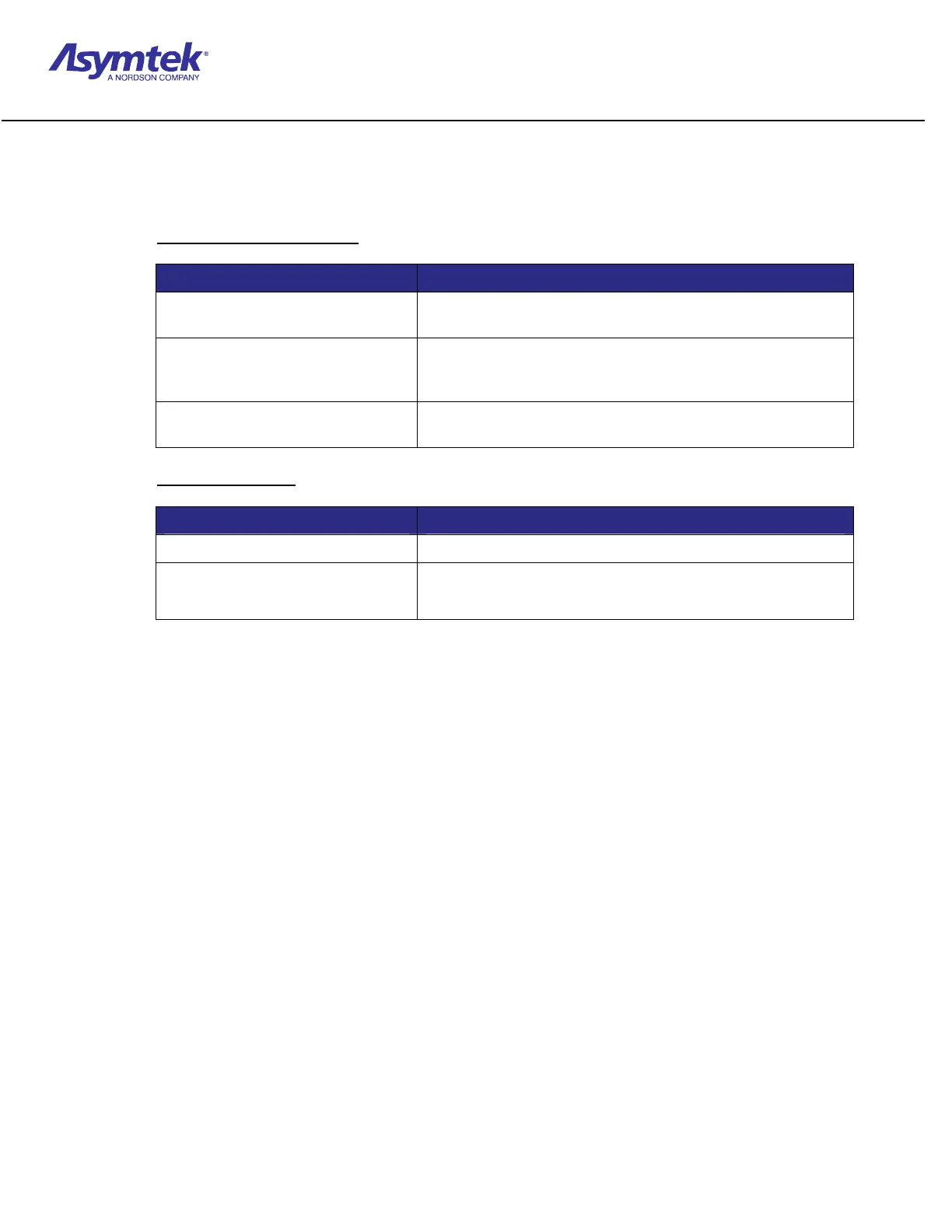

E. Shots Too Large

Possible Cause Recovery

1. Needle is too big 1. Replace needle with a smaller needle.

2. Syringe air pressure set too

high

2. Decrease syringe air pressure (20 psi max.). Refer to

the system Operations Manual for instructions.

Loading...

Loading...