Trainee Guide TR-L2-M2000

Level 2 Maintenance Training - M2000 Dispensing Systems 2-2-76 P/N 73-0018-00 (Revision B)

Information Sheet 2-10-1

Needle Heaters

A. Heating Element Compatibility

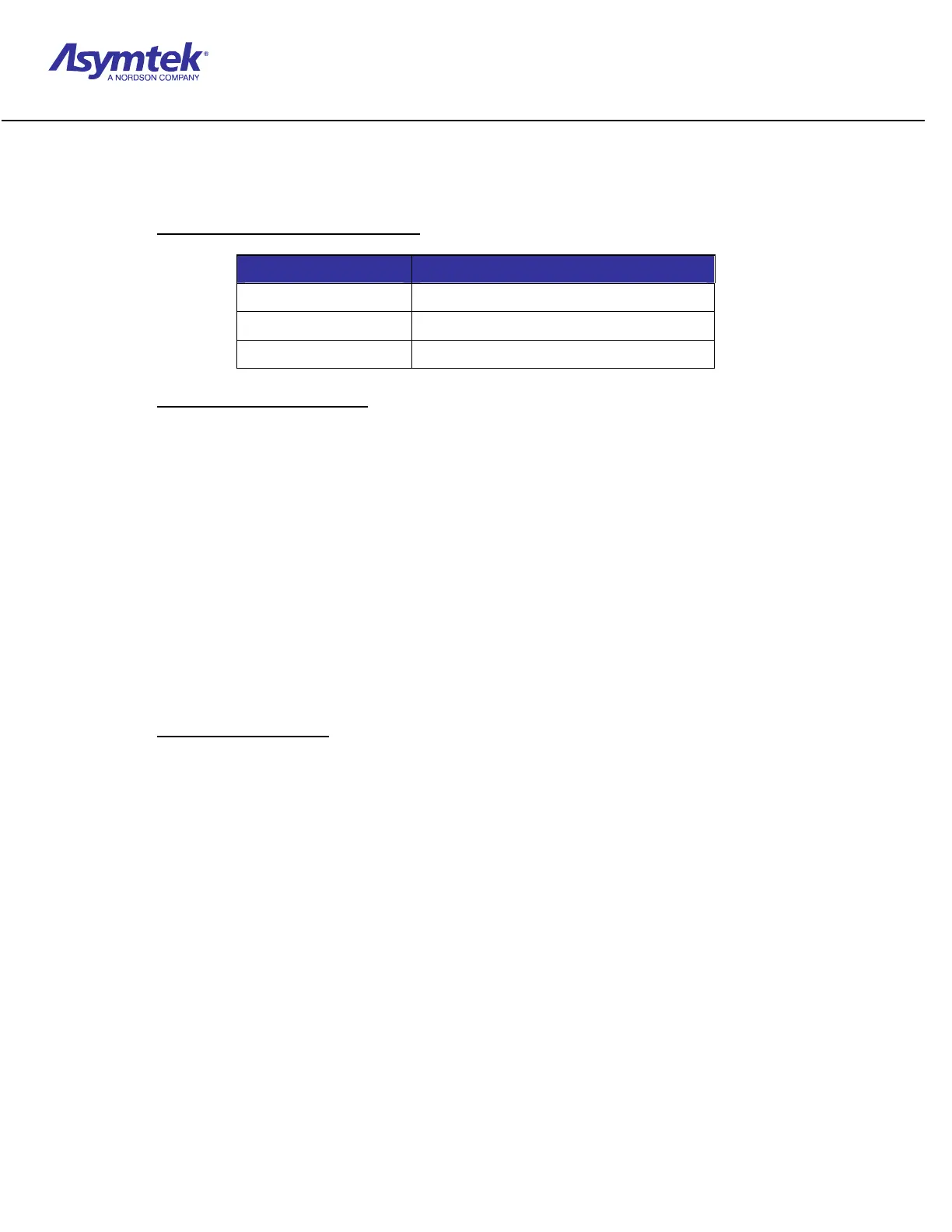

Heating Element Valve Compatibility

HT-04 Asymtek DV-04 valve only

HT-06 All Asymtek valves except DV-04

HT-10N All Asymtek valves using metal needles

B. Temperature Controllers

1. The HT-1000 is a temperature controller for a needle heater.

2. The HT-2000 is made up of two independent temperature controllers.

3. Both the HT-1000 and HT-2000 are used with heating elements to heat fluid in the

needle.

Heating the fluid keeps the fluid viscosity constant and helps maintain consistent

fluid flow.

Heating epoxies and adhesives eliminates “stringing” and compensates for

improperly defrosted two-part epoxies.

Heating the fluid at the needle eliminates chemical reactions and changes in

fluid properties that can occur if the entire fluid reservoir is heated.

C. Theory of Operation

1. The heating element attaches to the needle or to the valve tip, depending on the

type of heating element used. The temperature is set with the temperature

controller.

2. In FMW and FmNT, the temperature is set within the Fluidmove software. In

FMDOS, the temperature is set directly with the temperature controller.

3. A thermocouple cable connects the heating element to the temperature controller,

allowing the temperature controller to sense the heating element temperature.

The temperature controller adjusts the voltage to the heating element until the

heating element is at the desired temperature.

The heat is transferred to the dispensing needle. The needle is heated. Fluid

flowing inside the needle is also heated.

Loading...

Loading...