3-8 Troubleshooting

7000-TD002A-EN-P – September 2007

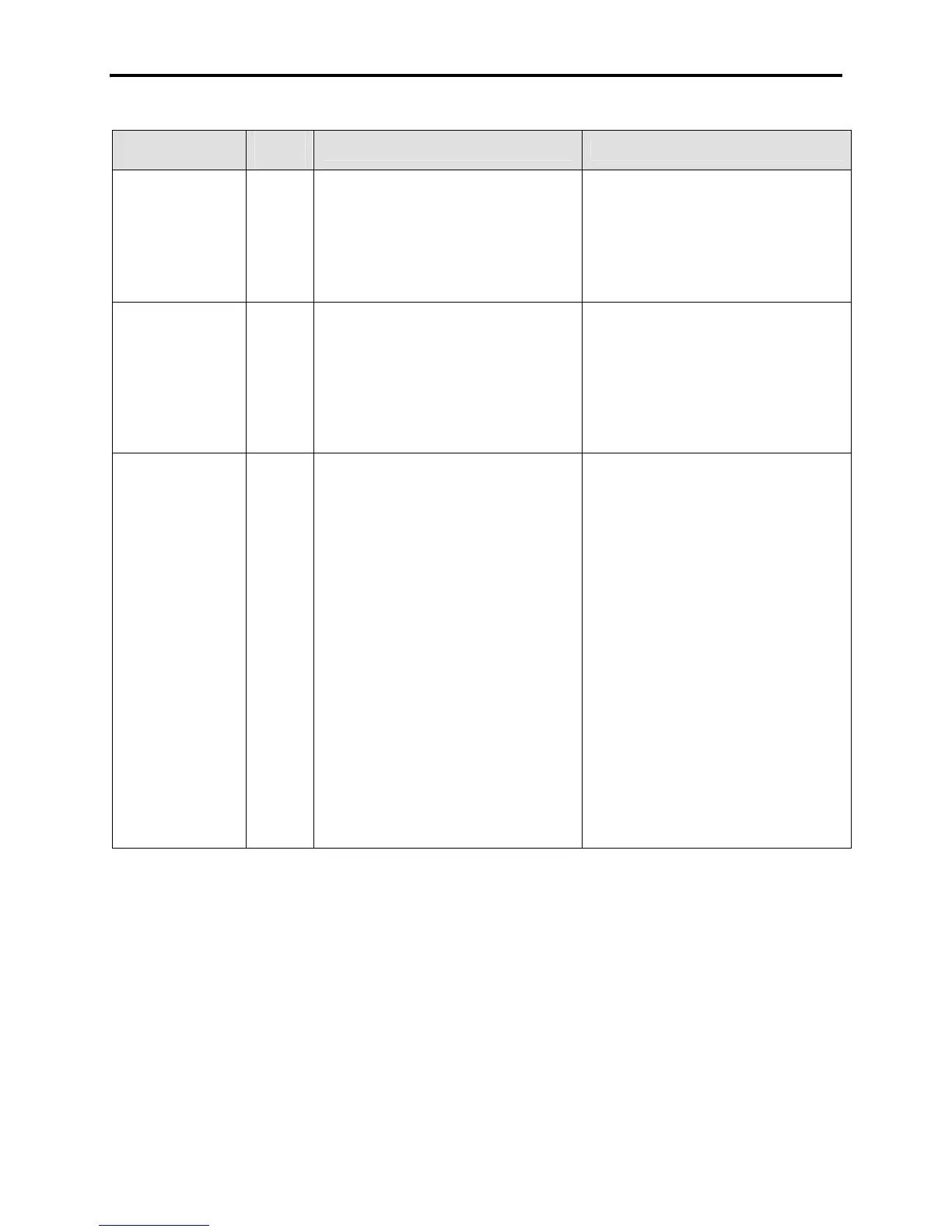

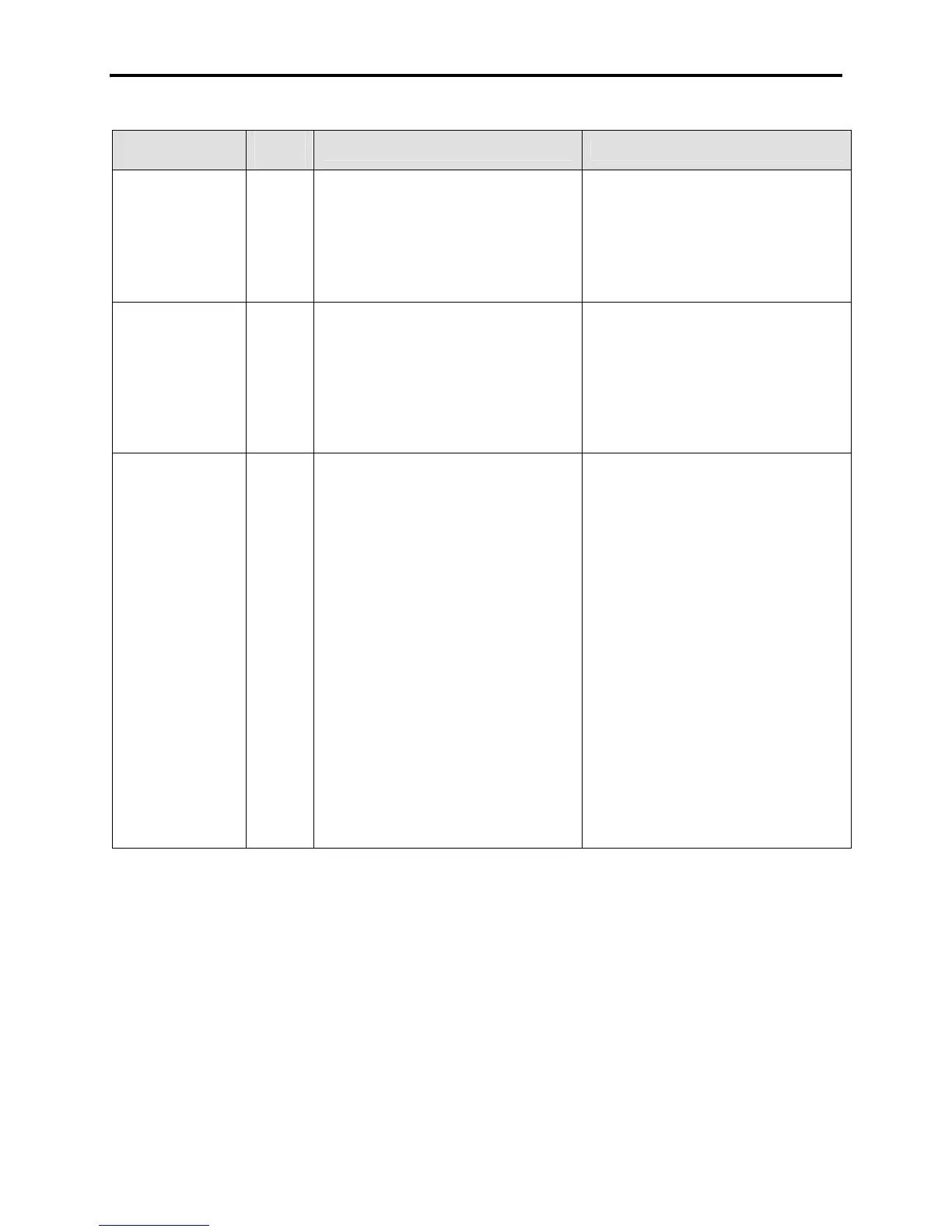

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION RECOMMENDED ACTIONS

DAN Comm Loss 456 Drive Area network communication fault.

This is applicable to parallel drive only

This fault is for parallel drives only and

indicates a loss of the Drive Area Network

(DAN) link for a drive acting as a Slave.

This would result in the slave drive stopping.

– Check RS485/RS232 converter. Red

LED should be steady, and green and

yellow transmit and receive LEDs should

be flashing.

– Check RS485 cable between drives

– Check RS232 cable between ACB Board

and serial converter

DC Link Flow Low

(C-Frame Only)

72 The flow switch in the DC Link coolant path

has detected the flow is less than optimal,

indicating a problem with the flow path. This

is not designed to specifically measure flow.

This is a switch that differentiates between

flow and no flow.

– Verify pressure values in the cooling

system are nominal

– Verify the cooling path is not restricted

because of tube crimping

– Check flow switch for proper operation

– It may be required to disconnect cooling

path and complete a check on the DC

Link for blockages

DClnk OvrCurrent 113 The DC Link current given by Idc Feedback

(P322) has exceeded the DC Link current

trip settings(P169). Verify the parameter

settings of the drive. Check the HECS and

burden resistor. Confirm stable operation of

the drive and any sudden load transients.

– Verify that the parameters for drive and

device ratings, and installed current

sensing components are set accordingly

– Verify that the DC Link HECS is wired

properly and properly powered

– Verify the Burden Resistor value

– Complete a DC Current Test to verify the

feedback corresponds to the IDC

Command

– Setup trending to capture DC Link

current Feedback and other related read-

only parameters (Contact factory if you

require assistance)

– Check Alpha Line, and verify that the

value is not too low (15°) and the current

regulator is not in limit; Decrease Flux

Command Base Speed or increase

incoming Line Voltage

– Restart the drive to allow the start up

diagnostics to detect any shorted

thyristors, but only attempt this once if

shorted SCRs are detected

Loading...

Loading...