Troubleshooting 3-9

7000-TD002A-EN-P – September 2007

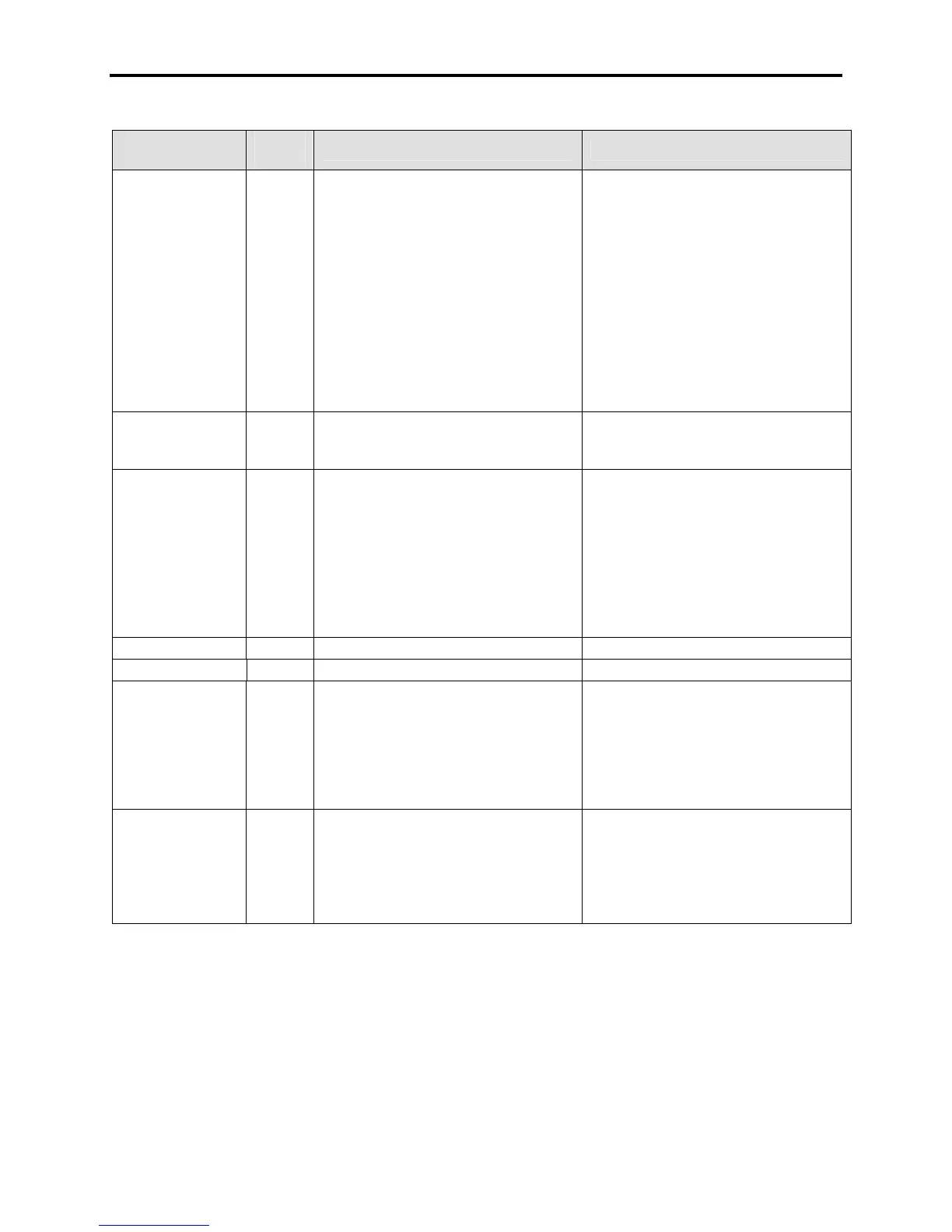

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION RECOMMENDED ACTIONS

DCLnk OvrTemp 34 The thermal switch in the DC Link inductor

has detected an over temperature condition

and opened the AC input to the standard

XIO. Ensure that the converter cooling fan is

working and that the air flow is not

obstructed. Also check the 120V wiring and

the XIO card. There is a thermal switch in

each DC Link winding, and they are

connected in series.

– Verify operating conditions (ambient/

altitude/ load levels/ ventilation and fans)

and verify that the DC Link Reactor is

within ratings

– Check the 120V signal through the

thermal switch

– Verify the drive cooling circuit is

operating correctly

– Check the XIO board inputs and

parameter status bits

– Determine through elimination whether

there is a faulty switch and replace if

necessary

DC Neutral VSB 461 This fault indicates that the voltage sensing

board associated with the dc and neutral

voltages is not plugged in.

– Check connector J25.

– Verify connection from VSB to ACB.

Drive OvrLoad 144 Drive Overload Trip (P163) as the absolute

trip level, Drive Overload Delay (P164) as

the base trip delay, and Drive Overload Min

(P269) as initial detection level.

The drive has detected an overload

condition in the dc link indicated by Drive

Overload (P551).

– Transient Loading – Check torque limit

and overload settings and compare

loading to torque settings and trip

settings

– Open Burden Resistor – Check Current

feedback and check the burden resistors

– Verify the drive sizing and that the

overload parameters to meet the load

requirements.

DvcAnodCath/Snub 154 Device Anode-Cathode or Snubber fault – NOT USED

Drv Output Open 161 NOT USED – NOT USED

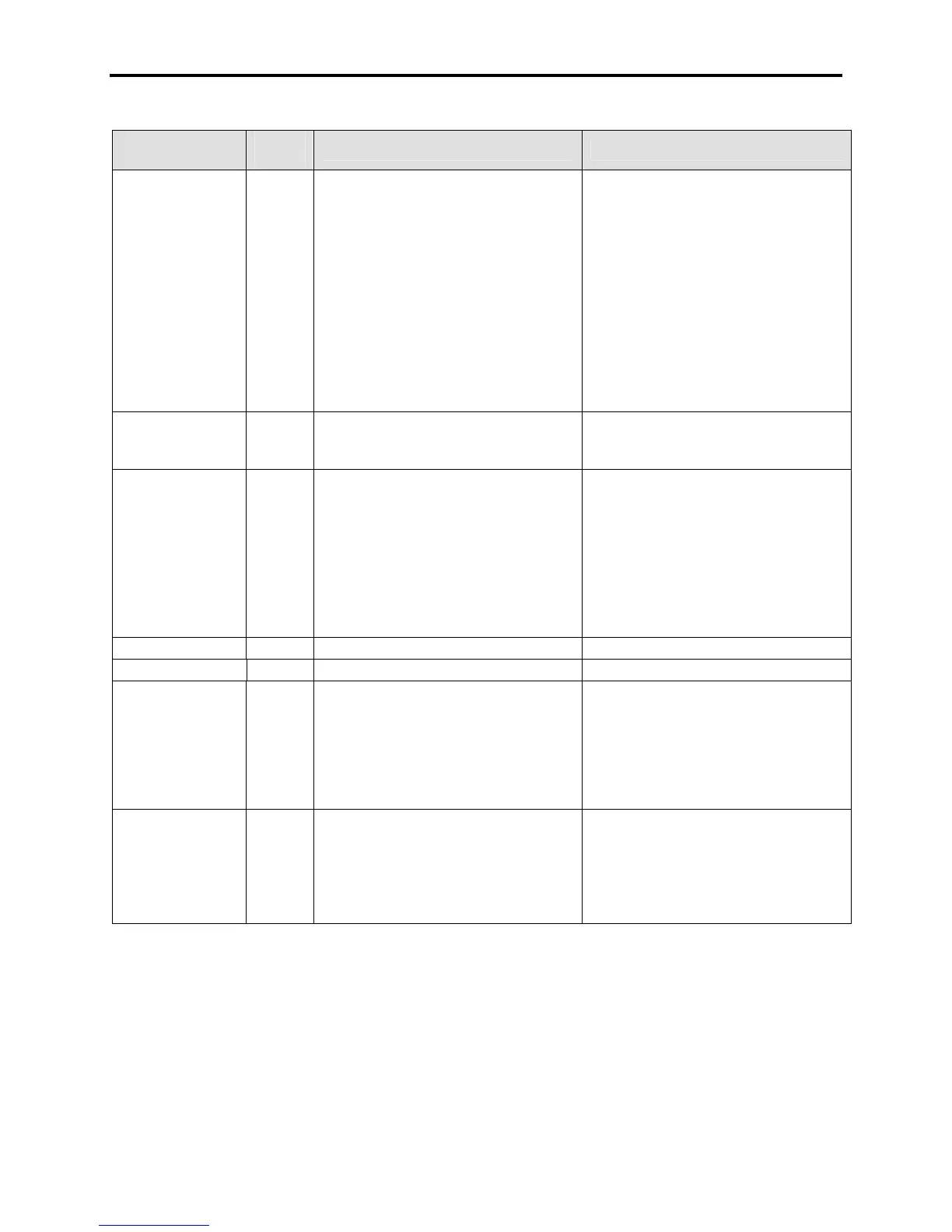

External 1-16 1-16 These are the optional additional External

Faults available when there is an additional

XIO board installed. This is configured with

XIO Ext Faults (P593), and this message

will appear if the specific input (1-16) is

configured in Fault Config as a Class 1 or

Class 2 fault.

– Review XIO Board Drawing:

– Identify source of Input from External

Fault XIO Board print and investigate the

cause of the fault

– Verify voltage signals from external

sources

Ext Cooling Loss

(C-Frame only)

65 The drive has detected the loss of the ability

to provide cooling for the drive. This is

detected through feedback from the Heat

Exchanger Cooling fans contactors and

overloads.

– Review the inputs to the drive Liquid

Cooling XIO and determine the source of

the missing signals

– Investigate the Heat Exchanger fans and

control for a cause

– Check the liquid cool XIO card.

Loading...

Loading...