3-22 Troubleshooting

7000-TD002A-EN-P – September 2007

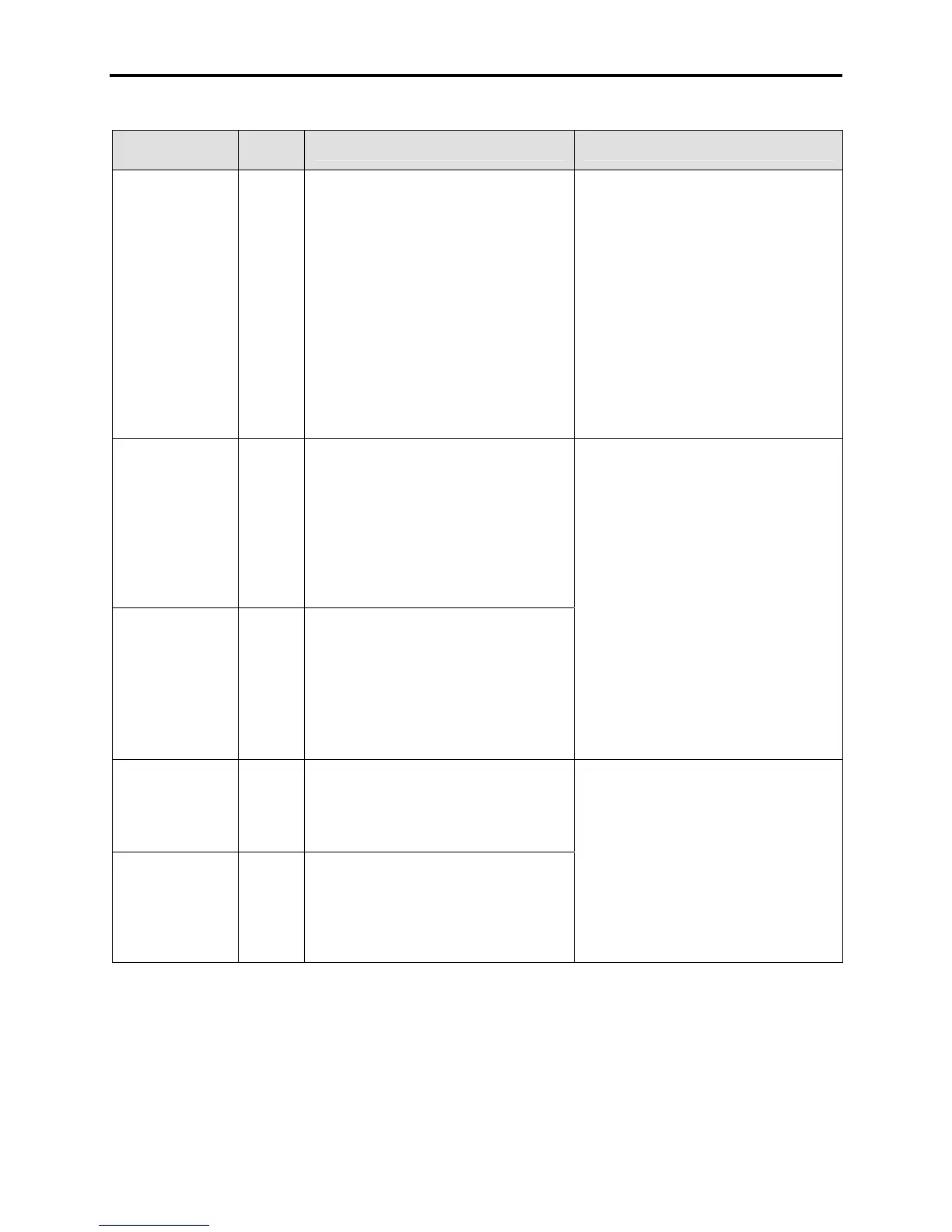

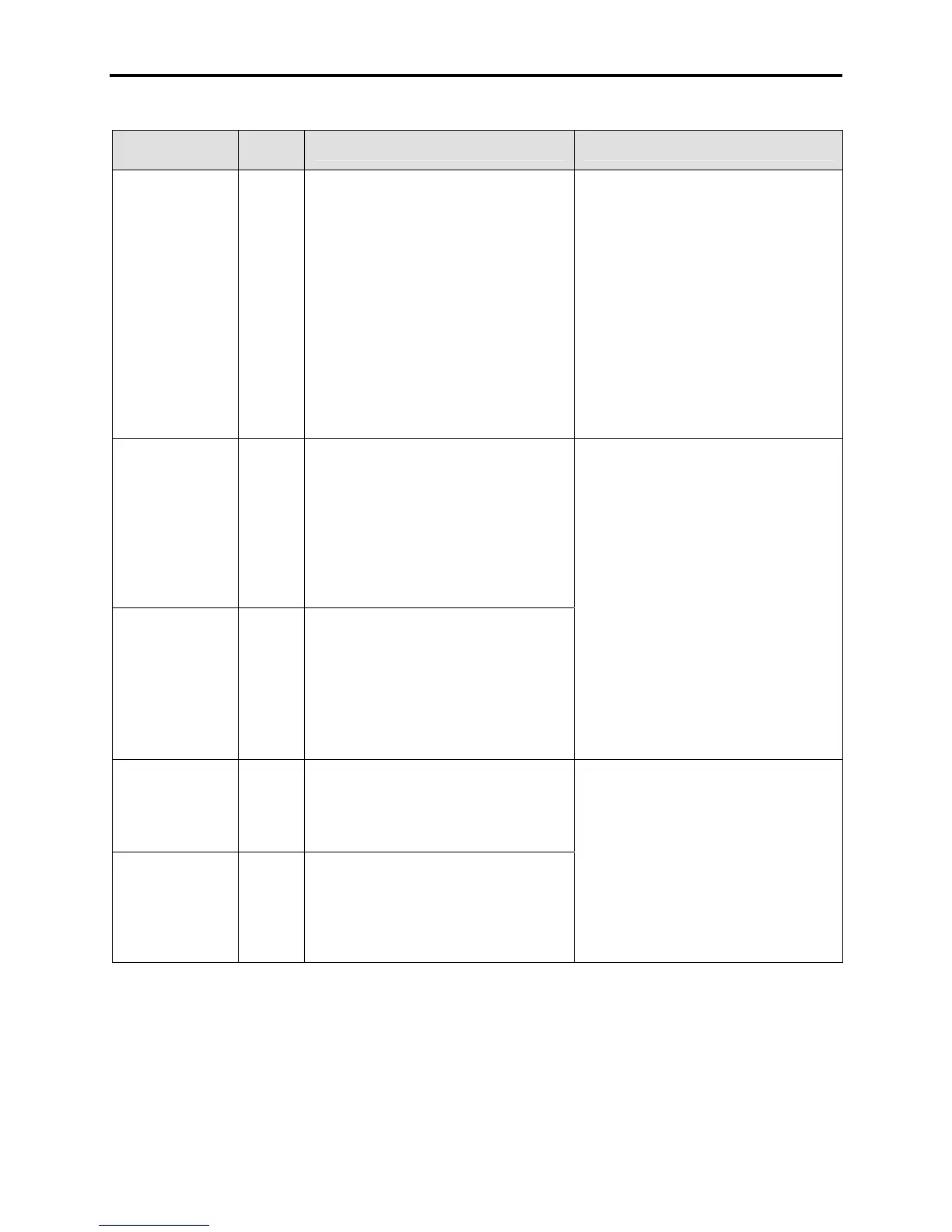

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION RECOMMENDED ACTIONS

RNeutral OvrLoad 145

The neutral resistor required for Direct-to-

Drive technology has reached an overload

condition. This is determined from

parameters Neutral Resistor (P680), R

Neutral power Rating (P681). The current

through the neutral resistor is calculated by

measuring the voltage across the resistor

and knowing the resistance. Common Mode

current (P697) displays that current, and R

Neutral OL (P682) shows the overload

accumulator. The resistor is allowed 500%

for 10 seconds every 5 minutes, and P682 is

normalized to fault whenever the value

reaches 1.00.

– Verify the resistor ratings

– Verify that the drive Voltage Feedback

Splitter board is operating properly

– Investigate the possibility of voltage

unbalances on the input or output of the

drive that would create a voltage

differential across the resistor

– Contact the factory for further instructions

– Verify the resistor parameters.

– Investigate the cause of neutral shift

between the input and output filter

capacitors which could be due to severe

line transients or insulation failure.

– Megger the drive if necessary.

Slave1 CurUnbal 124 The level of unbalance in the input current of

the Slave1 Bridge displayed in Slave1 Cur

Unbal (P614) has exceeded the value of the

trip settings (P108). Verify the CTs, burden

resistors and connections on the ACB.

Investigate the incoming source voltage for

unbalance.

Slave2 CurUnbal 125 The level of unbalance in the input voltage

of the Slave 2 Bridge displayed in Slave2

Cur Unbal (P615) has exceeded the value of

the trip settings (P108). Verify the CTs,

burden resistors and connections on the

ACB. Investigate the incoming source

voltage for unbalance.

– Verify that all Current Transformer

connections are connected properly and

that no wires are reversed – Ring-out

wires to verify connections

– Check grounding on CTs

– Ensure that all plugs are firmly

connected in the ACB

– Check that all input voltages are

balanced

– Verify Parameter settings

– Check the burden resistors

– Verify the Input Capacitor values if

installed

– Verify that there are no open sharing

resistors

– Verify all Line Thyristors are firing in

Gating Test Mode

Slave1 Phasing 126 The drive has detected that the phasing in

the Slave1 bridge is incorrect. Verify the

cables are terminated correctly.

Slave2 Phasing 127 The drive has detected that the phasing in

the Slave2 bridge is incorrect. Verify the

cables are terminated correctly.

– Verify cables are terminated correctly

– Verify the feedback wires from the

terminals to the VSB is terminated correctly

– The faults can be masked, and then the

voltages and phasing can be checked

using the test points on the ACB, being

aware that there will be phase

differences between the master and

secondary bridges depending on the

drive configuration. Refer to

Commissioning chapter of the Manual.

Loading...

Loading...