Troubleshooting 3-23

7000-TD002A-EN-P – September 2007

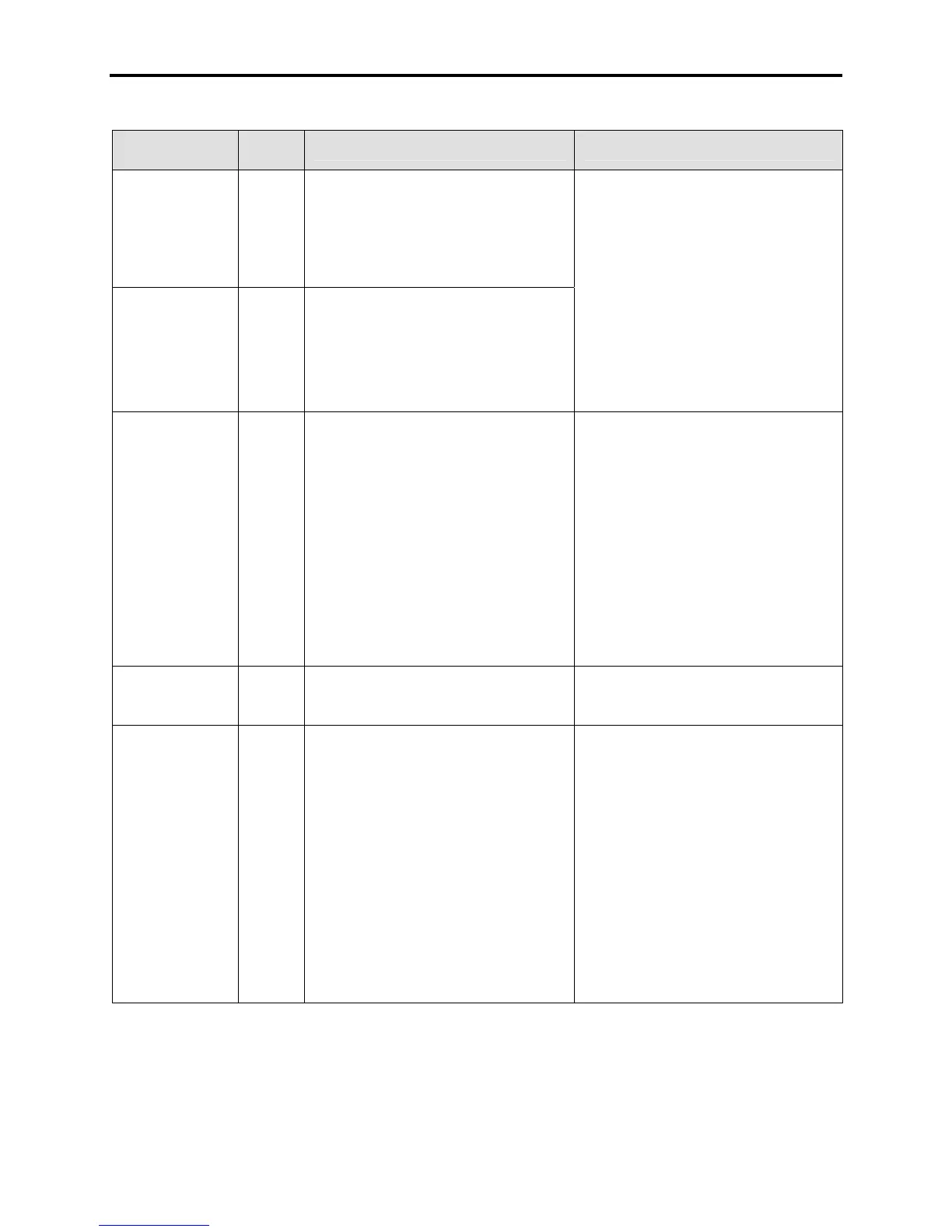

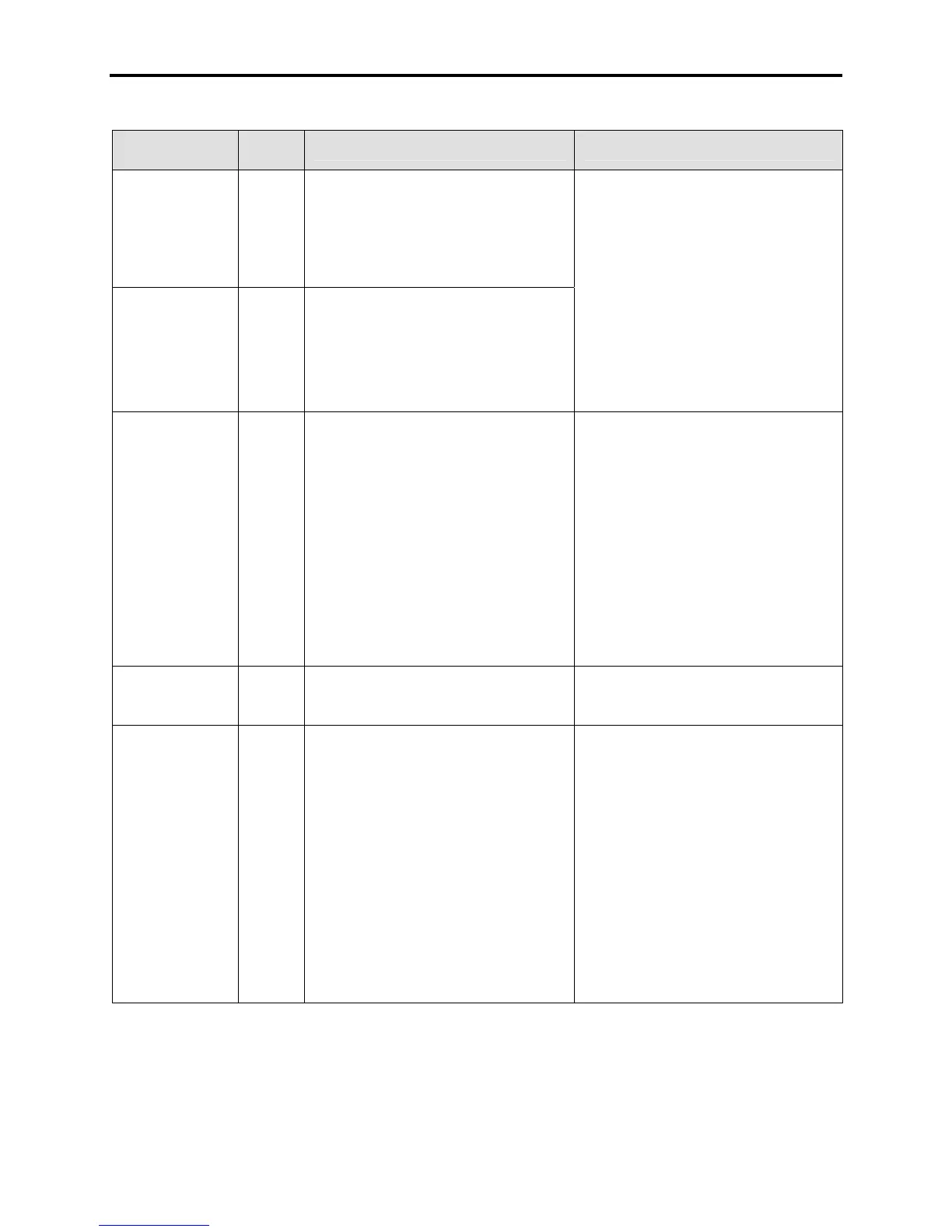

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION RECOMMENDED ACTIONS

Slave1 VoltUnbal 121 The level of unbalance in the input voltage

of the Slave 1 Bridge displayed in Slave1

VoltUnbal (P611) has exceeded the value of

the trip settings in (P271). This fault is valid

only for 18-pulse rectifier.

Slave2 VoltUnbal 122 The level of unbalance in the input voltage

of the Slave 2 Bridge displayed in Slave2

VoltUnbal (P610) has exceeded the value of

the trip settings in (P271). This fault is valid

only for 18-pulse rectifier.

– CHECK TSN FUSING

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm

integrity

– Check actual voltage values on the

Operator Interface terminal for each

bridge and the total line voltage

– Check for possible source voltage supply

problems

– Use Multimeter and Oscilloscope to

check voltages on the drive voltage test

points

Speed Cmd Loss 23

The drive has lost communication with the

device responsible for providing the speed

command to the drive. This has been set to

annunciate as a fault. The drive will

configure the Speed Command Loss as a

fault when the associated bit in DPI Loss

Mask (P175) is set to a 1. Setting the bit to

0 will cause the drive to indicate a warning

and run at the last commanded speed.

The fault could be the DPI adapter or the 4-

20mA signal wired to the analog input (IFM

board). Ensure that all connections are

secure, device is powered and operating

correctly.

– Ensure that the communication device is

powered

– Verify the light status and ensure the

communicating device is operating properly

– Verify the customer network is properly

communicated with the device

– Check ACB LED status

– Cycle control power to the drive

– Change the Adapter and/or ACB if all

attempts to restore communication fail

– Ensure that all connections at IFM are

secure, device is powered and operating

correctly.

Sync VSB 460 This fault indicates that the voltage sensing

board associated with the synchronous

transfer voltages is not plugged in.

– Check connector J25 at ACB

– Verify the ribbon cable connection from

Sync VSB to ACB board.

Sync Xfer Failure 162 A Synchronous Transfer was not completed

in the time specified in Synchronous

Transfer Time (P230) and the drive has

faulted. This fault will only occur if the

parameter Sync Xfer Option is configured as

Enable Fault. If the parameter is set as

Enable Warn, the drive will go back to last

speed command and issue a warning.

– Instability at Synchronous Speed - Check

for stability of the synchronous transfer

process/ speed regulator

– Motor can not reach Synchronous Speed

due to heavy load

– Check load conditions for torque limit or

low alpha line (low line voltage)

– Consult factory for review of

synchronous transfer parameters

– This fault indicates that the drive failed to

synchronize the motor to the bypass

within the specified time. Adjust the Sync

Reg Gain (P225), Sync Error Max

(P228), Spd Reg Bandwidth (P81) for a

smooth transfer.

Loading...

Loading...