5.10 Detailed Troubleshooting

256 YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07)

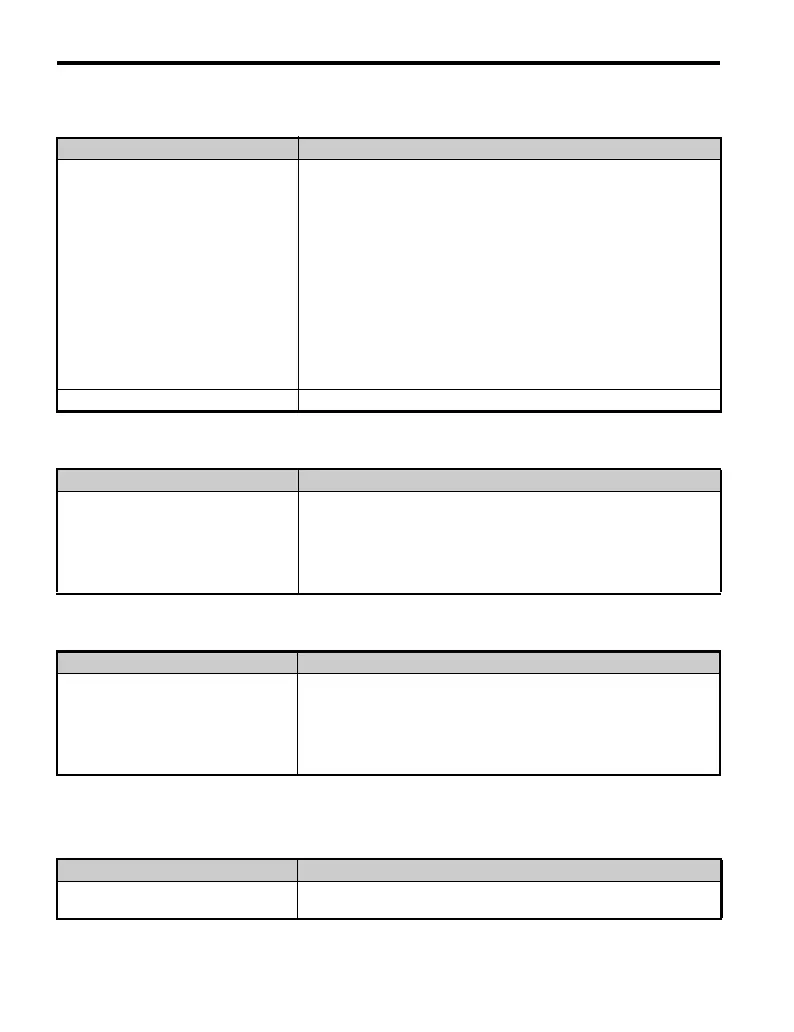

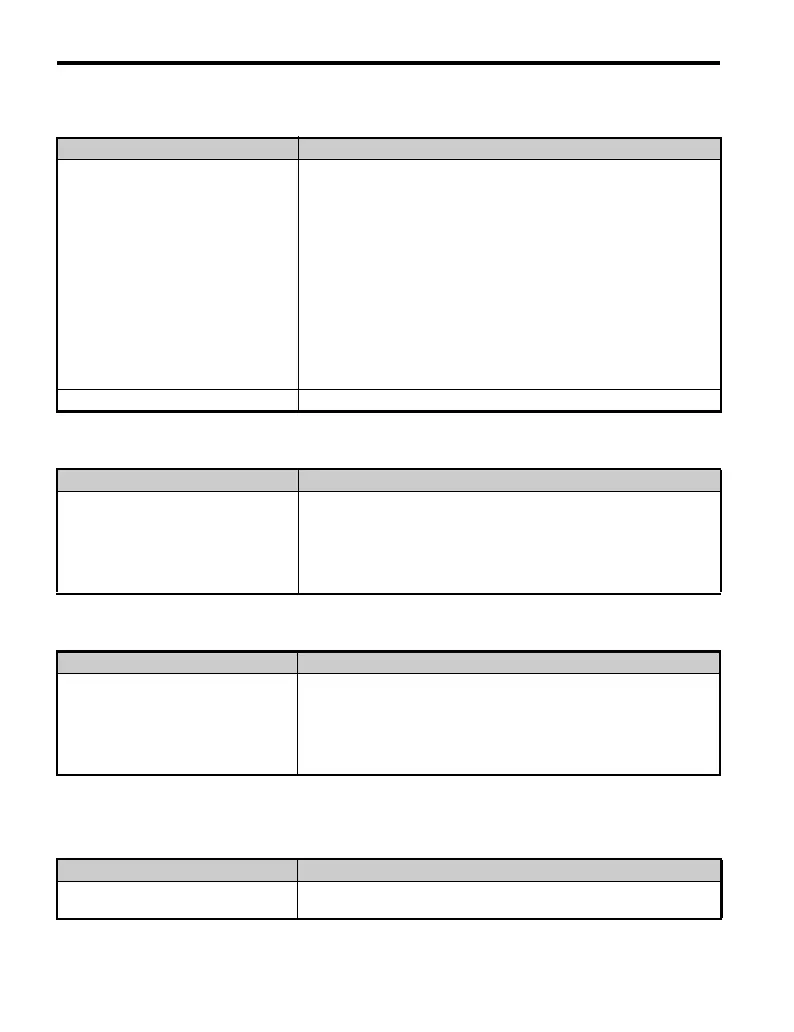

■ Load Falls When Brake is Applied (Hoist-Type Applications)

■ Noise From Drive or Output Lines When the Drive is Powered On

■ Ground Fault Circuit Interrupter (GFCI) Trips During Run

■ Connected Machinery Vibrates When Motor Rotates

Excessive Motor Oscillation and Erratic Rotation

Cause Possible Solutions

The timing for the brake to close and

release is not set properly.

• Use frequency reference detection for closing and releasing the brake.

• At start: Release the brake after creating enough torque.

• At stop: Close the brake when the motor still produces torque.

• Make the following setting changes to hold the brake:

• Set the multi-function contact output terminal MA, MB, MC for

frequency detection.

• Multi-function contact output terminal will switch off when the output

frequency is greater than the frequency detection level set in L4-01. Set

L4-01 between 3.0 and 5.0 Hz.

• Slipping may occur when stopping because hysteresis is used in

Frequency Reference 2 (where the frequency agree setting in L4-02 is

2.0 Hz). To prevent this, change the setting to 0.5 Hz.

• Do not use the multi-function contact output setting “During Run”

(H2-01 = 0) for the brake signal.

Insufficient DC Injection Braking. Increase the amount of DC Injection Braking (b2-02).

Cause Possible Solutions

Relay switching in the drive generates

excessive noise.

• Lower the carrier frequency (C6-02).

• Install a noise filter on the input side of drive input power.

• Install a noise filter on the output side of the drive.

• Place the wiring inside a metal conduit to shield it from switching noise.

• Ground the drive and motor properly

• Separate the main circuit wiring and the control lines.

Cause Possible Solutions

Excessive leakage current is tripping

MCCB.

• Decrease the sensitivity of the GFCI, or use a different GFCI with a

higher threshold.

• Lower the carrier frequency (C6-02).

• Reduce the length of the cable used between the drive and the motor as

much as possible.

• Install a noise filter on the output side of the drive.

Cause Possible Solutions

Poor balance between motor phases.

Check the drive input power voltage to ensure that it provides stable

power.

Loading...

Loading...