5.10 Detailed Troubleshooting

258 YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07)

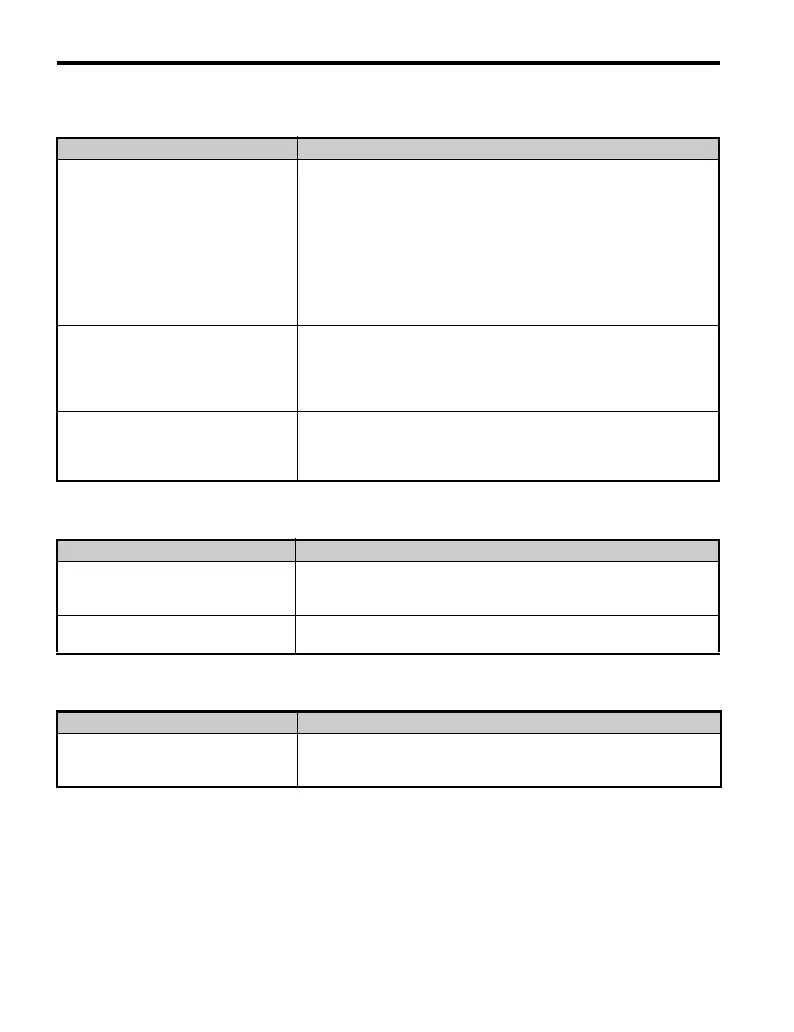

■ PID output fault

■ Insufficient Motor Torque

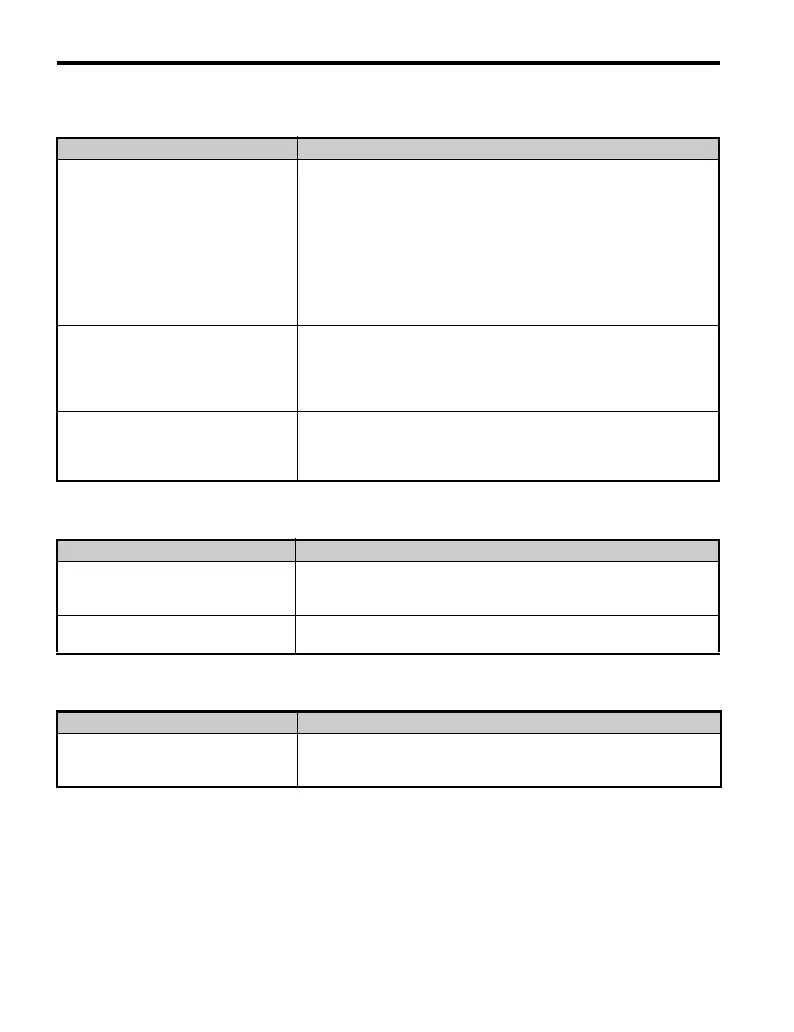

■ Motor Rotates After the Drive Output is Shut Off

Cause Possible Solutions

No PID feedback input.

• Check the multi-function analog input terminal settings.

• Set multi-function analog input terminal A1 or A2 for PID feedback

(H3-02 or H3-10 = “B”).

• There should be an actual signal input into the multi-function terminal

selection for PID feedback.

• Check the connection of the feedback signal.

• Check the various PID-related parameter settings.

• If there is no PID feedback input to the terminal, the value detected will

be 0, which will cause a PID fault and the drive will operate at the

maximum frequency.

The level of detection and the target

value do not correspond with each other.

• PID control keeps the difference between the target value and detection

at 0. For this reason, the input level for the detection value and the target

value need to be set relative to one another.

• Use the analog input gains H3-03/11 to adjust the scaling of the PID

target and feedback signals.

Drive output frequency and speed

detection are reversed. When the output

frequency goes up, the sensor detects a

decrease in speed.

Set PID output for reverse characteristics (b5-09 = “1”).

Cause Possible Solutions

Auto-Tuning has not yet been performed

(required for Open Loop Vector

Control).

Perform Auto-Tuning.

Only Line-to-Line Resistance

Auto-Tuning was performed.

Perform Rotational Auto-Tuning.

Cause Possible Solutions

The DC Injection Braking current is too

low and the drive cannot decelerate

properly.

• Adjust the DC Injection braking settings.

• Increase the value of b2-02 (DC Injection Braking Current).

• Increase the b2-04 (DC Injection Braking Time at Stop).

Loading...

Loading...