6.2 Ins pection

274 YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07)

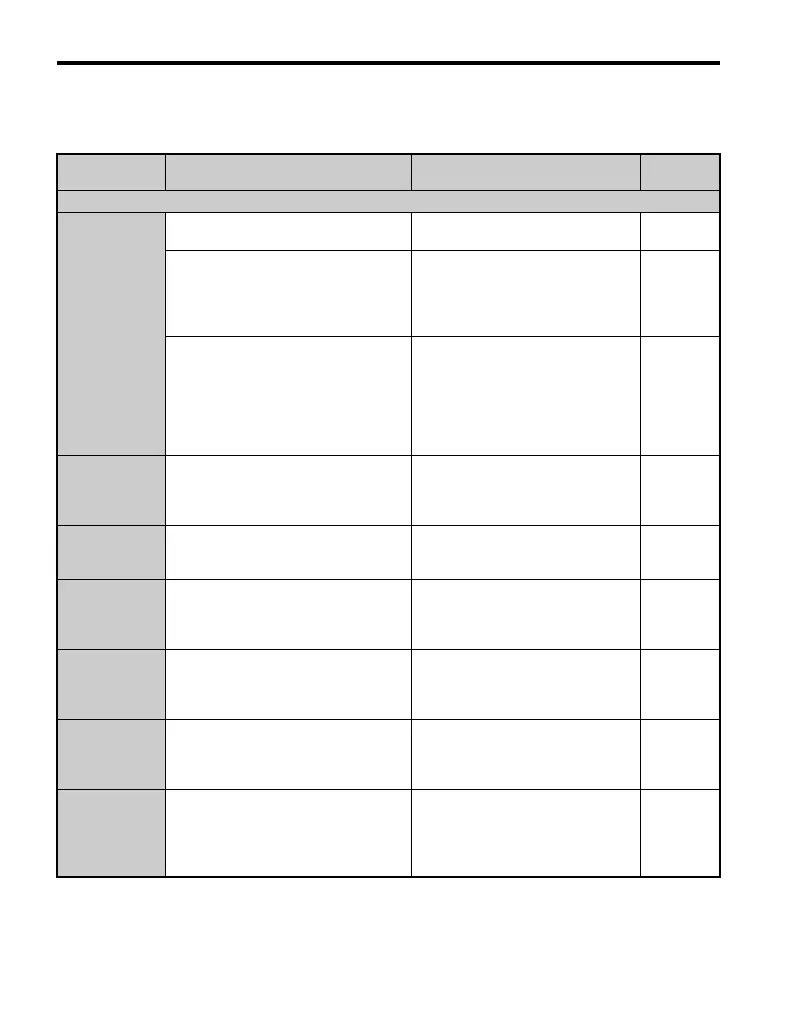

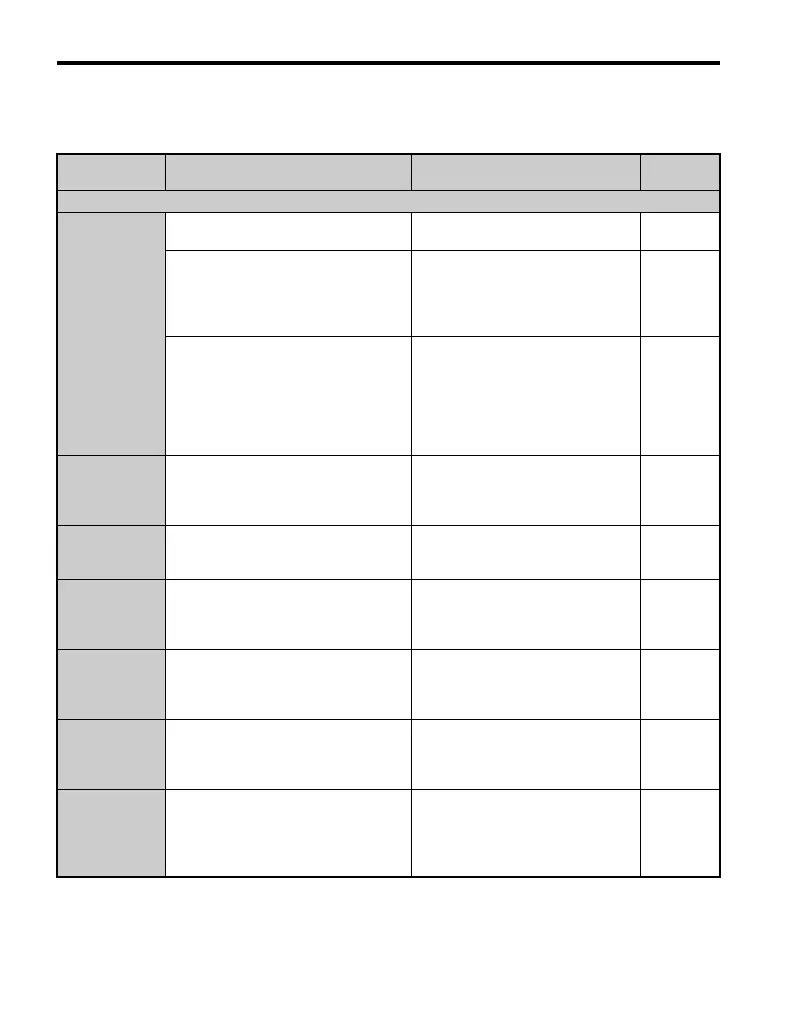

■ Periodic Inspection

Table 6.2 Periodic Inspection Checklist

Inspection

Area

Inspection Points Corrective Action Checked

Main Circuit Periodic Inspection

General

• Overall check of the main power circuit

and ground terminals

Take appropriate actions

(e.g., tightening loose connections).

• Inspect equipment for discoloration from

overheating or deterioration.

• Inspect for damaged or deformed parts.

• Replace damaged components as

required.

• The drive has few serviceable parts

and may require complete drive

replacement.

• Inspect for dirt, foreign particles, or dust

collection on components.

• Inspect enclosure door seal if present.

Replace components if cleaning is not

possible.

• Use dry air to clear away foreign

matter. Use a pressure of

39.2 ξ 10

4

to 58.8 x 10

4

Pa

(4 - 6 kg •cm

2

).

Conductors and

Wiring

• Inspect wiring and connections for

discoloration, damage, or heat stress.

• Inspect wire insulation and shielding for

wear.

• Repair or replace damaged wiring.

Termina ls

• Inspect terminals for stripped, damaged,

or loose connections.

• Check for tightness.

• Tighten loose screws and replace

damaged screws or terminals.

Relays and

Contactors

• Inspect contactors and relays for

excessive noise during operation.

• Inspect coils for signs of overheating

such as melted or cracked insulation.

• Check coil voltage for over or under

voltage conditions.

• Replace damaged removable relays

contactors or circuit board.

Braking

Resistors

• Inspect for discoloration of heat stress on

or around resistors.

• Minor discoloration may be

acceptable.

• If discoloration exists check for loose

connections.

Electrolytic

(bus) Capacitors

• Inspect for leakage, discoloration, or

cracks.

• Inspect the relief valve for swelling,

rupture, or leakage.

• The drive has few serviceable parts

and may require complete drive

replacement.

Diodes and

IGBTs

• Inspect for accumulation of dust or other

foreign particles on components.

• Use dry air to clear away foreign

matter.

• Use a pressure of

39.2 ξ 10

4

to 58.8 ξ 10

4

Pa

(4 - 6 kg •cm

2

).

Loading...

Loading...