6.2 Inspection

YASKAWA TM.V1000.01 V1000 Drive Installation & Start-Up Manual (Preliminary 01-19-07) 275

Periodic Inspection &

Maintenance

6

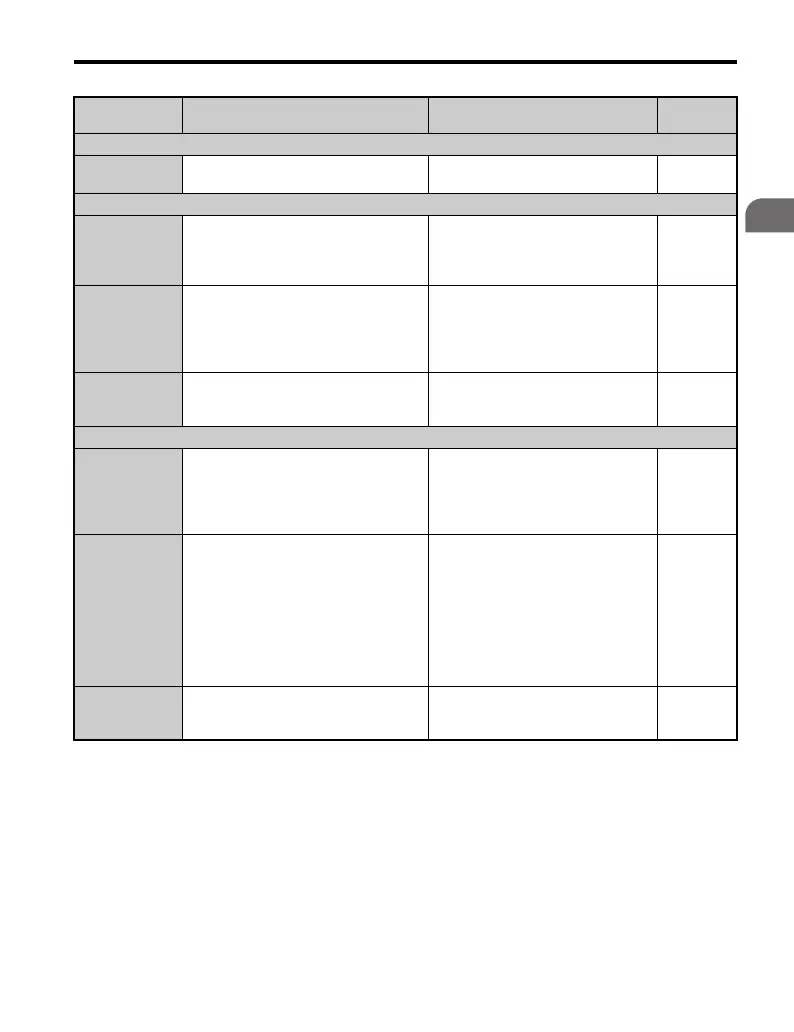

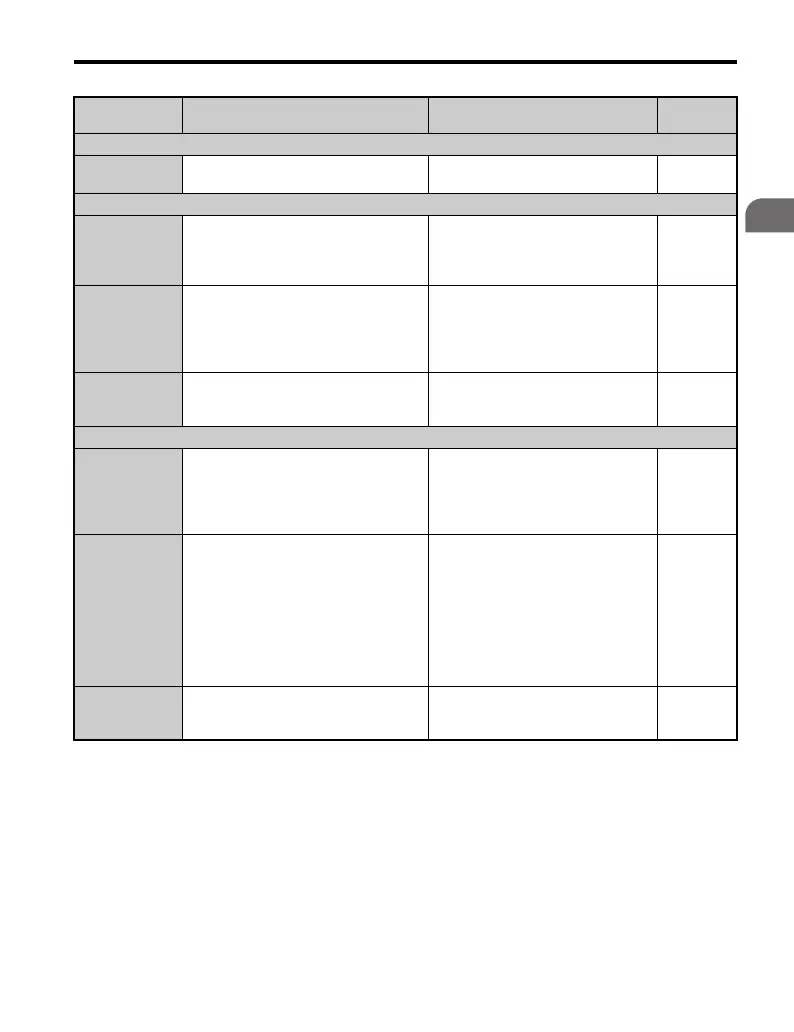

Motor Periodic Inspection

Operation

Check

• Check for increased vibration or

abnormal noise.

• Stop the motor and contact qualified

maintenance personnel as required.

Cooling System Periodic Inspection

Cooling Fan

• Check for abnormal oscillation or

unusual noise.

• Check for damaged or missing fan

blades.

• Replace as required.

• Refer to Drive Cooling Fans on

page 278 for information on cleaning

or replacing the cooling fan.

Heatsink

• Inspect for dust or other foreign material

collected on the surface.

• Use dry air to clear away foreign

matter.

• Use a pressure of

39.2 ξ 10

4

to 58.8 ξ 10

4

Pa

(4 - 6 kg•cm

2

).

Air Duct

• Inspect air intake and exhaust openings.

They must be free from obstruction and

properly installed.

• Visually inspect the area.

• Clear obstructions and clean air duct

as required.

Control Circuit Periodic Inspection

General

• Inspect terminals for stripped, damaged

or loose connections.

• Check for tightness.

• Tighten loose screws and replace

damaged screws or terminals.

• If terminals are integral to a circuit

board then board or drive replacement

may be required.

Printed Circuit

Boards

• Inspect for unusual discoloration,

burning or strange odor, noticeable rust

or corrosion, proper seating of

connectors, dust, oil, or other

contamination.

• Re-seat loose connectors.

• Replace PCBs if wiping or vacuuming

with anti-static vacuum cannot clean

the PCB.

• Do not use solvents on PCBs.

• Use dry air to clear away foreign

matter. Use a pressure of

39.2 ξ 10

4

to 58.8 ξ 10

4

Pa

(4 - 6 kg •cm

2

).

Electrolytic

Capacitors

• Inspect for leakage, discoloration, or

cracks.

• The drive has few serviceable parts

and may require complete drive

replacement.

Inspection

Area

Inspection Points Corrective Action Checked

Loading...

Loading...