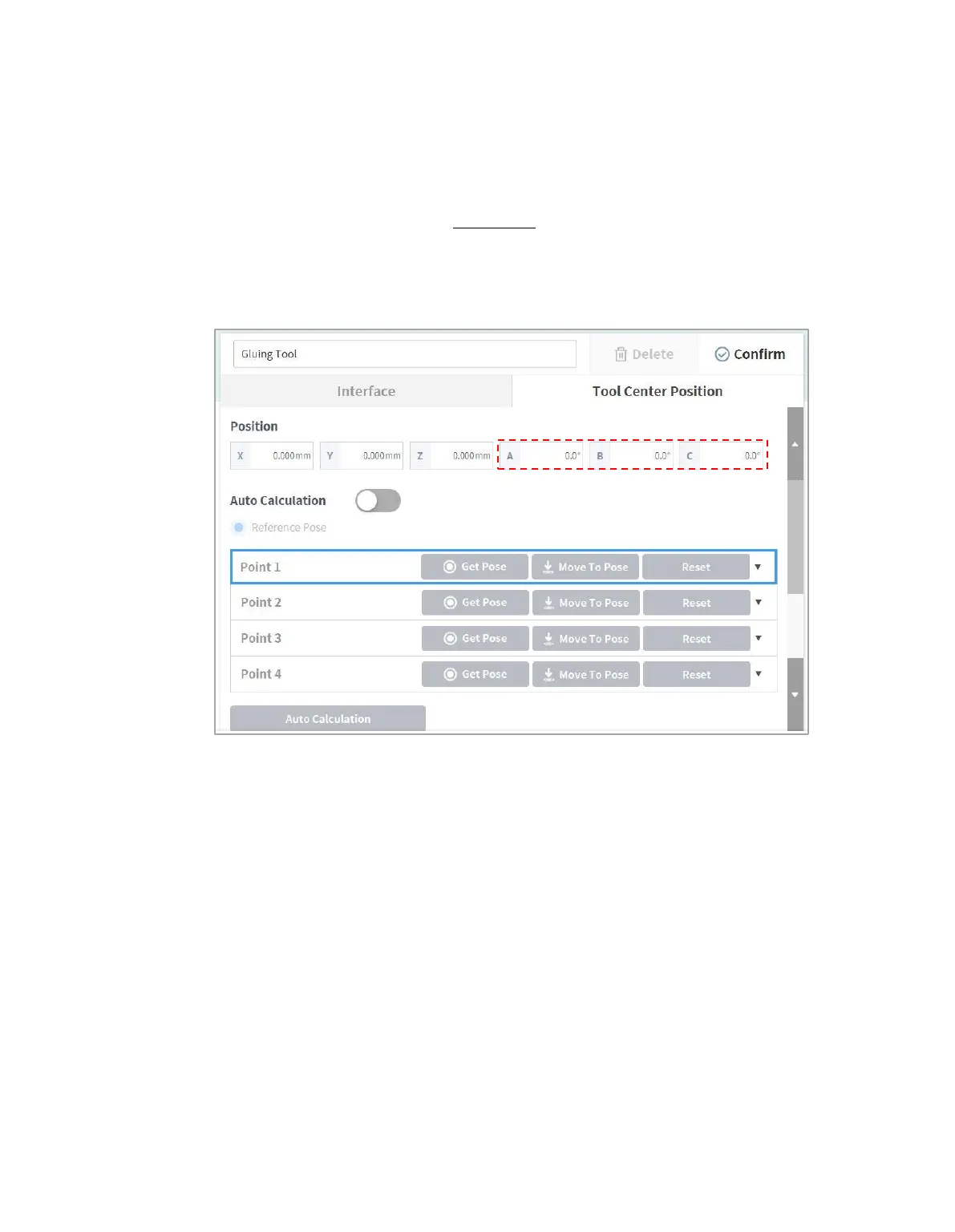

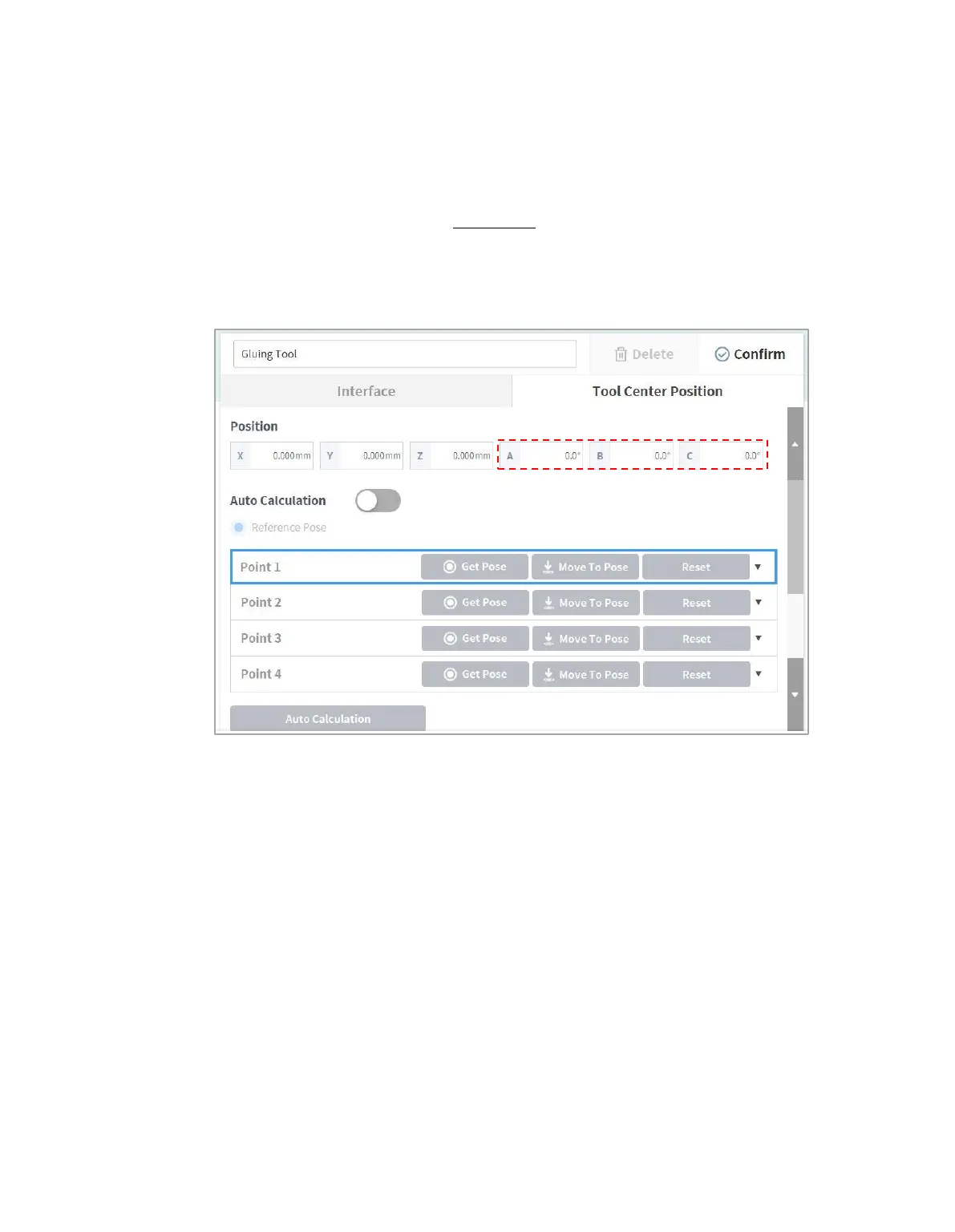

7.6.4 Tool Center Point (TCP) Setting

When configuring the tool center point (TCP), the position and rotation angle based on the flange

coordinates must also be defined. The distance from the default starting point of the flange coordinate

to the tool center point (TCP)in the X, Y and Z directions cannot be set to be greater than 10000 mm.

In addition, if the converted lengths (𝐿 =

√

𝑋

2

+ 𝑌

2

+ 𝑍

2

) of X, Y and Z are less than 300mm, force

control, compliance control, and direct teaching-point lock functions can be executed.

In particular, if the TCP is configured using Auto Calculate, the calculation is made based only on the

X, Y and Z positions, so it is necessary to enter the rotation angle. The rotation angle can be defined

with items A, B and C, and it is based on the Euler Z-Y-Z rotation method.

The definitions of the coordinate axis expressed with x, y, z and coordinate axis expressed with X, Y, Z

are as follows:

• Coordinate axis of “Flange Coordinate” (x, y, z): The coordinate axis direction defined at the end

of the flange is identical to the robot coordinate with a robot joint angle of (0,0,0,0,0,0).

• Coordinate axis of “TCP Coordinate” (X,Y,Z): The coordinate axis is defined at the end of the tool

installed on the end of the flange or working point. The rotation angle of the “TCP Coordinate” is

defined based on the “Flange Coordinate” in the order of 1) to 3) of the following:

Loading...

Loading...