Doosan Robotics User Manual v2.6.1

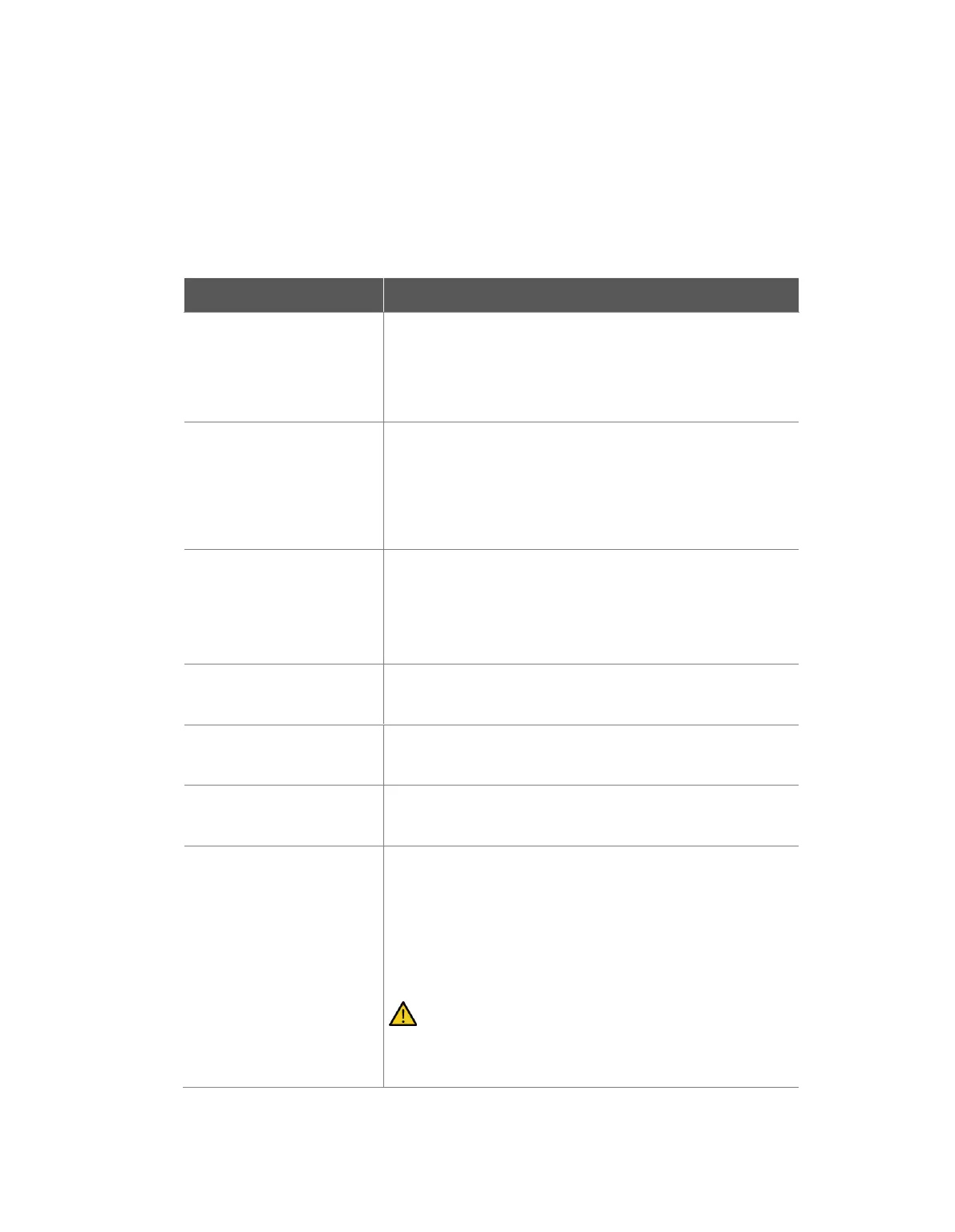

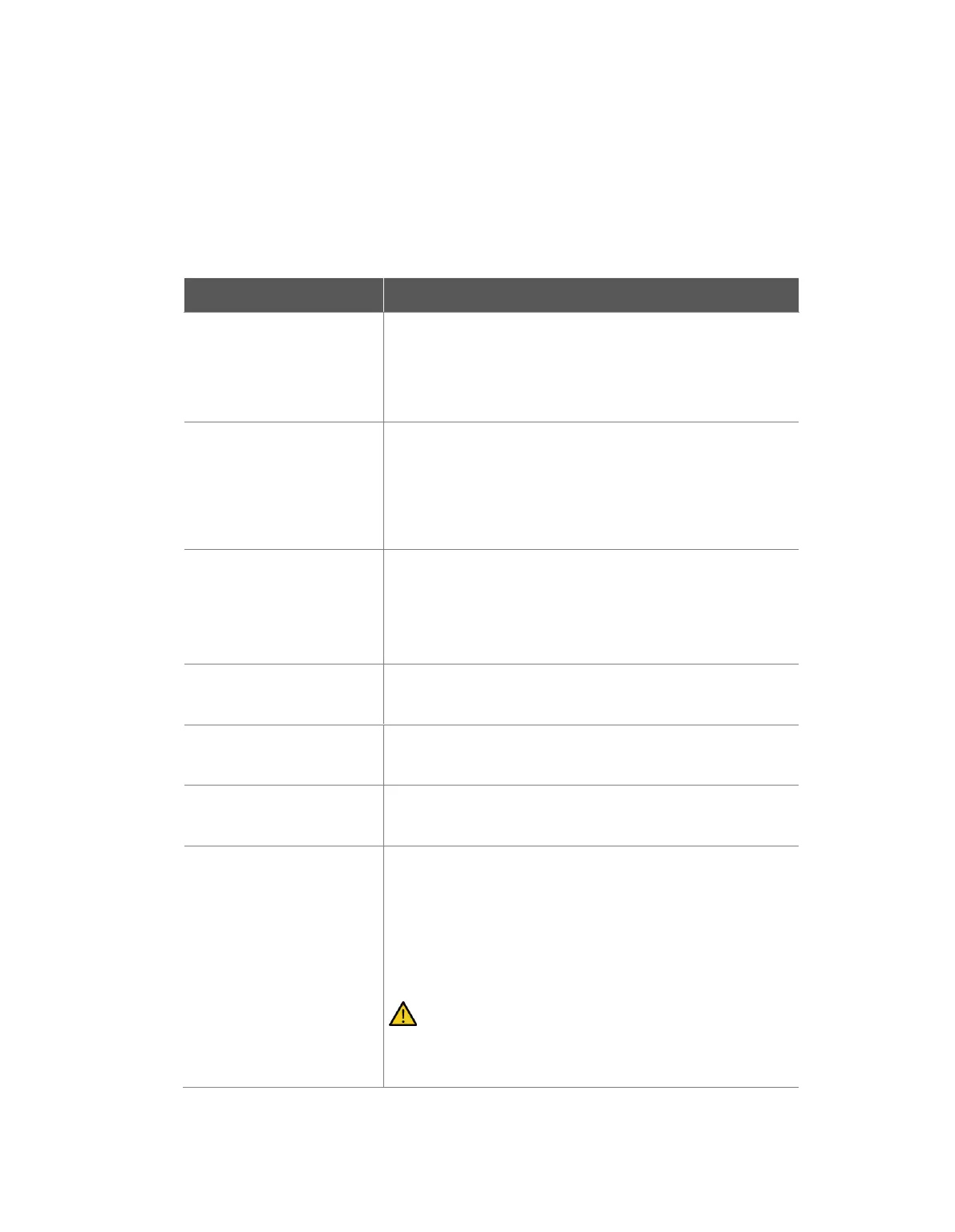

7.5.3 Safety I/O Setting

This function inputs/outputs safety-related signals through a redundant terminal. If a signal that is

different from the redundant safety input or output signal is detected, the system determines whether it

is a short circuit or hardware defect and stops the robot with STO Stop Mode. To set the Safety I/O, go

to the Robot Workcell and select Robot > Safety I/O.

• Safety Input Setting

It is an interface to receive emergency stop signal from

peripheral device, or connect additional emergency stop

switches.

High: Normal operation

Low: It stops the robot according to the stop mode setting for

Emergency Stop at the Safety Stop Mode.

Emergency Stop – No

Loopback (L)

It is an interface to receive emergency stop signal from

peripheral device, or connect additional emergency stop

switches. This signal doesn’t activate ‘Emergency Stop –

excl. No Loopback Input’ safety outp

High: Normal operation

Low: It stops the robot according to the stop mode setting

for Emergency Stop at the Safety Stop Mode.

It can be linked with Safeguarding Devices such as safety

matts, light curtains and laser scanners.

High: Normal operation

Low: It stops the robot according to the stop mode setting for

Protective Stop at the Safety Stop Mode.

High: Normal operation

Low: Immediately cuts the motor power and engages the

brakes to force the robot to stop.

High: Normal operation

Low: Cuts off the motor power and engages the brakes after

controlled stop.

High: Normal operation

Low: Position is maintained with power supplied to the

motor and the brake disengaged after controlled stop.

Protective Stop(L) - Auto

Reset & Resume (R)

Unlike the other Protective Stop, Interrupted state can be

reset and automatic operation can be resumed automatically

by this signal. This enables automatic restart after Safety-

rated Monitored Stop described in ISO TS 15066.

Low: Follow Protective Stop – SS2.

Rising (Low to High): the task resumes automatically

without manual reset or resume.

Warning

Resuming automatic operation without manual intervention can

be dangerous,

Loading...

Loading...