CNC 8055

CNC 8055i

·T· MODEL

SOFT: V02.2X

7

·125·

TABLES

In order to select a new tool, tool offset or zero offset, it is necessary that those values be previously

stored at the CNC.

The following tables may be used for that:

• Zero offset table.

It must be defined. It indicates each axis offset for each zero offset.

• Tool offset table.

It must be defined. It stores the dimensions of each tool.

•Tool table.

It must be defined. It indicates for each tool, the family it belongs to, the offset associated to it,

its nominal and real life spans, etc.

• Tool magazine table

It must be defined. It indicates the position each tool occupies in the tool magazine.

• Tool geometry table.

It must be defined. It indicates the dimensions and cutting angle of each cutter.

• Global and local parameters table.

It does not need to be defined.

It is updated by the CNC. When selecting a tool (T) or a tool offset (D), the CNC acts as follows:

We recommend to save the tables into the hard disk (KeyCF), a peripheral device or a PC.

When accessing the TABLES operating mode, the CNC will show the tables that are saved in the

hard disk (KeyCF).

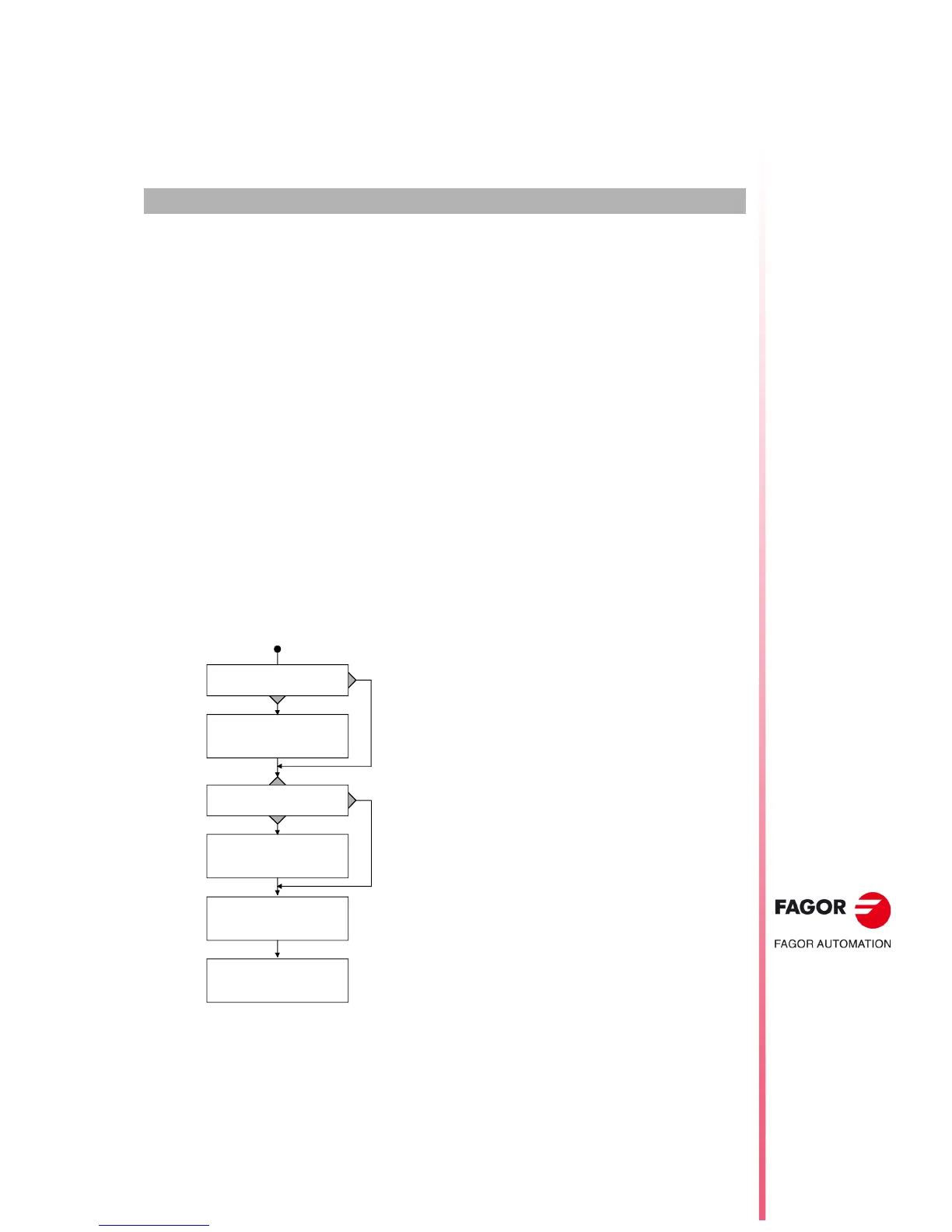

If the machine has a tool magazine, the CNC looks up the

table to know the position occupied by the selected tool and

the desired one.

If the "D" function has not be defined, the CNC looks up the

tool table to know the number of the offset associated with it.

The CNC looks up the tool offset table and assumes the tool

dimensions corresponding to the "D" offset.

The CNC analyzes the tool geometry table to know the

geometry of the cutter (width, angle and cutting angle). The

geometry will be associated with the tool or with the tool

offset, according to the manufacturer's criteria.

Loading...

Loading...