Operating manual

CNC 8055

CNC 8055i

MANUAL

6.

·T· MODEL

SOFT: V02.2X

·121·

Movement with an electronic handwheel

6.2.4 "Additive handwheel" mode

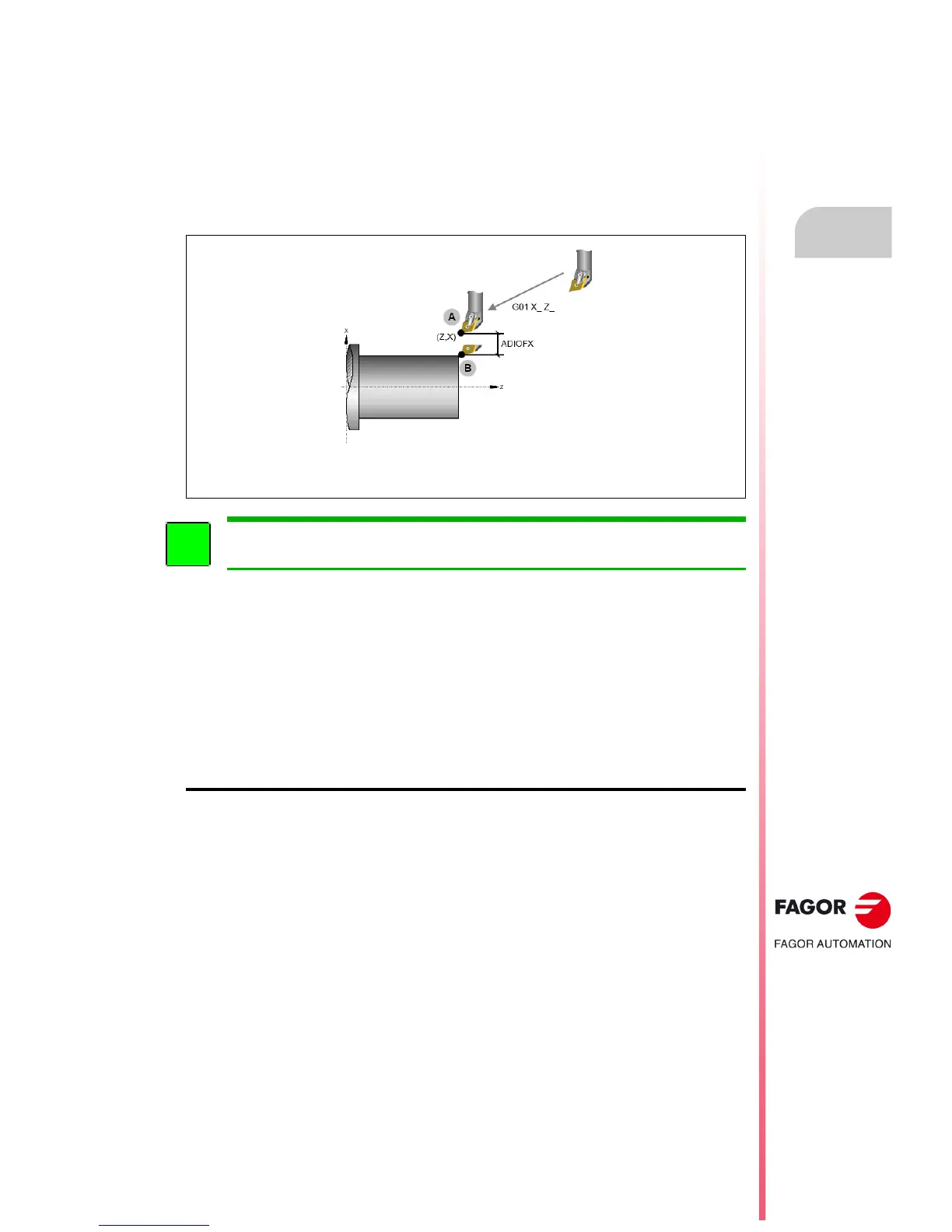

With manual intervention or additive handwheel, it is possible to move the axes manually while a

program is being executed. Once this option is activated, use the handwheel to make a movement

to be added to the one resulting from the automatic execution. This movement will be applied as

if it were another zero offset.

The general handwheel will be used as the additive handwheel. If there is no general handwheel,

use the individual handwheel associated with the axis. Only one additive handwheel may be enabled

at a time; the CNC will only attend to the first enabled handwheel.

The intervention with an additive handwheel is only possible in execution mode, even while the

program is interrupted. However, it is not allowed in the tool inspection mode.

If the additive handwheel is enabled for a coordinate transformation G46 (incline axis), the

handwheel movements are applied to the machining operation even if they are not shown on the

graphics screen.

The offset caused by the additive handwheel stays active after disabling the handwheel and it is

reset to zero after a home search. The offset stays active or is reset after an M02 or M30 and after

an emergency or a reset depending on the setting of axis machine parameter ADIMPG.

Considerations to the additive handwheel.

The movement with the additive handwheel on the master axis is also applied to the slave axis when

using axes that are gantry, slaved or synchronized by PLC.

When testing the software limits during block preparation, it checks the theoretical coordinate

ignoring the additional movement of the additive handwheel.

The mirror image by PLC is not applied to the additive handwheel movement.

Loading...

Loading...