·178·

Operating manual

CNC 8055

CNC 8055i

10.

PLC

·T· MODEL

SOFT: V02.2X

Monitoring

10.3.1 Monitoring with the PLC in operation and with the PLC stopped

It must be borne in mind that the CNC initializes all physical outputs and the PLC resources on power-

up, after the key sequence [SHIFT]+[RESET] and after detecting a watchdog error at the PLC.

The initialization process sets all resources to "0" except those active low. They will be set to "1".

During the monitoring of the PLC program and the various PLC resources, the CNC will always show

the real values of the resources.

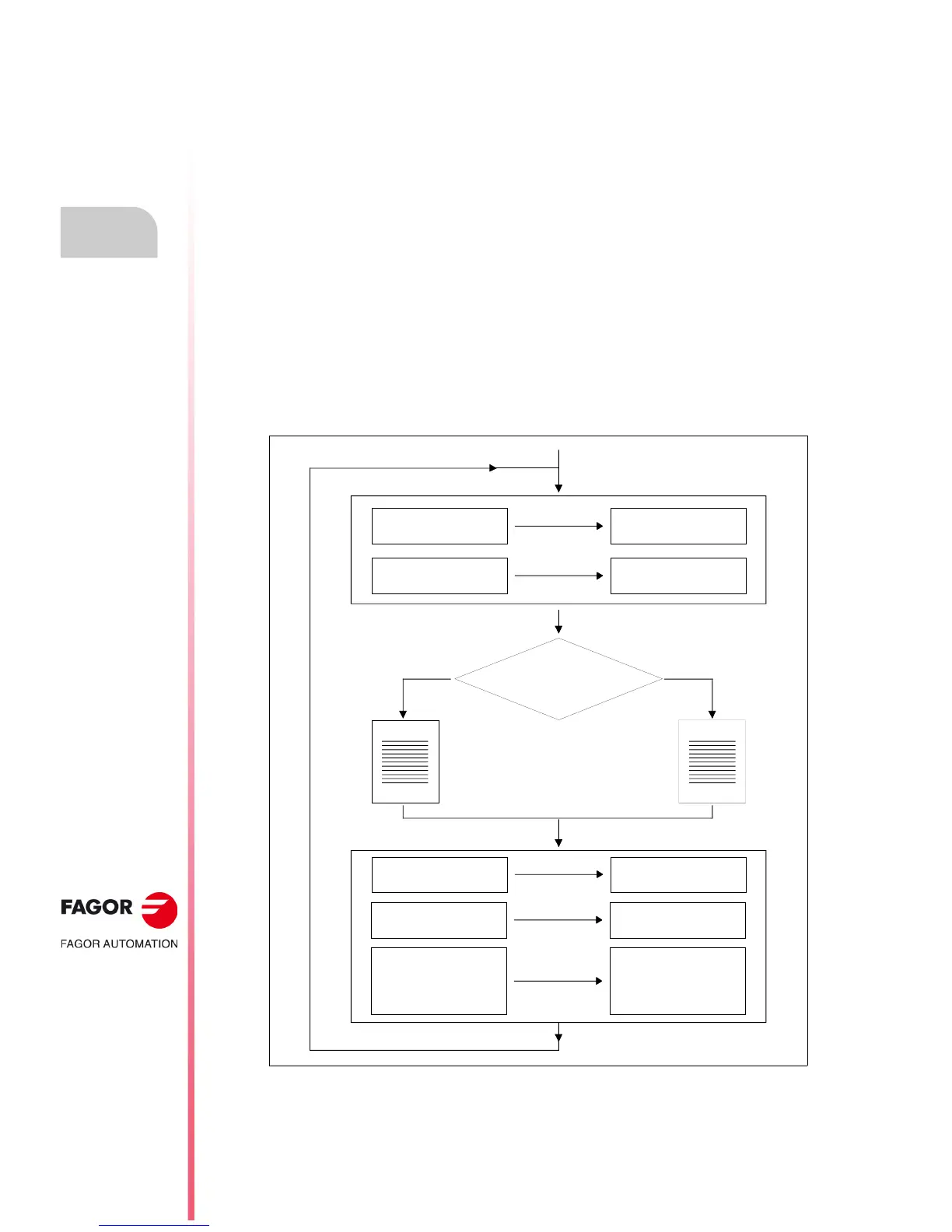

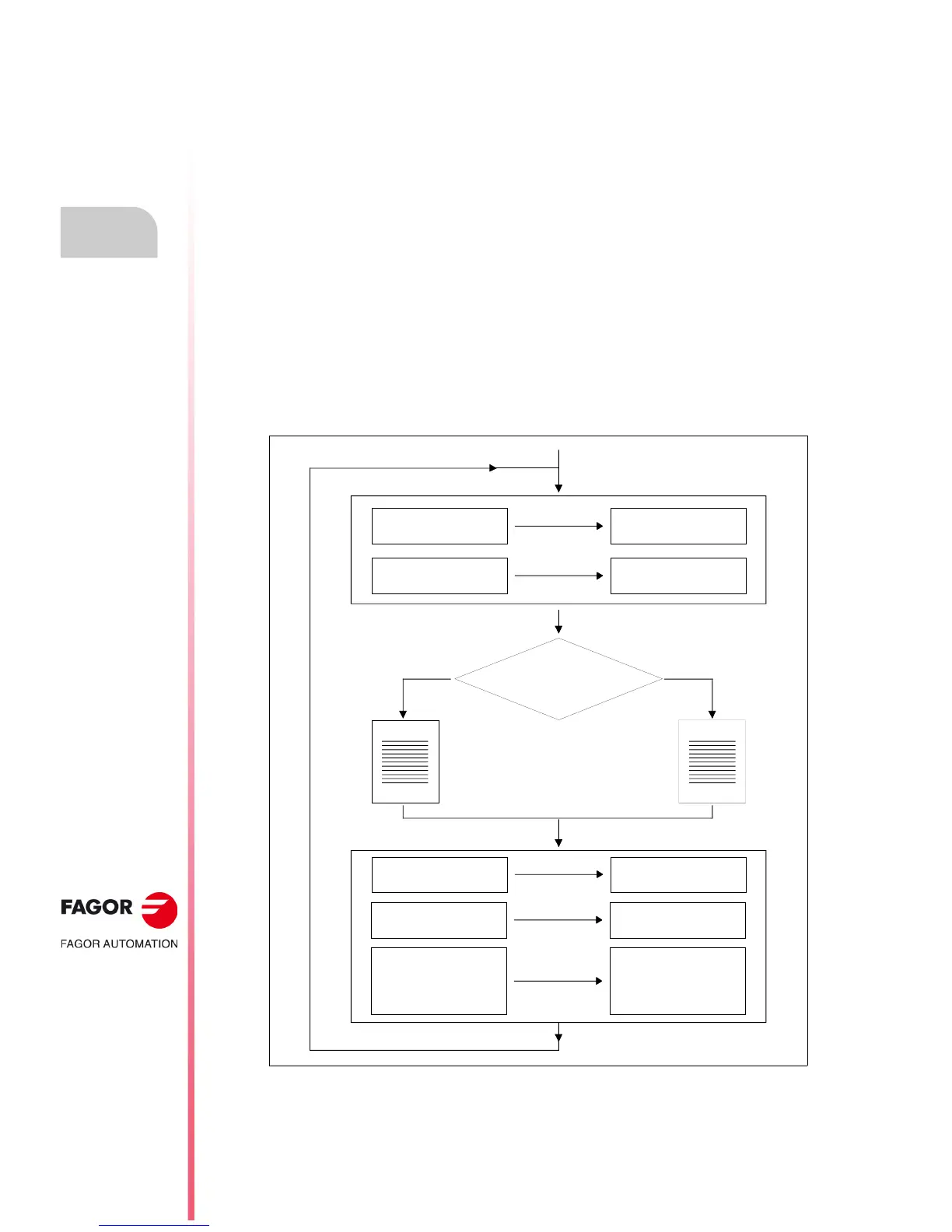

If the PLC is on, note that a program cycle is processed in the following way:

• The PLC updates the real input values after reading the physical inputs (from the electrical

cabinet).

• It updates the values of resources M5000 thru M5957 and R500 thru R559 with the values of

the CNC logic outputs (internal variables).

• It runs the program cycle.

• It updates the CNC logic inputs (internal variables) with the real values of resources M5000 thru

M5957 and R500 thru R559.

• It assigns to the physical outputs (electrical cabinet) the real values of the corresponding "O"

resources.

• It copies the real values of resources I, O, M into their own images.

Physical inputs Real inputs

Logic CNC outputs M5500 - M5957

R550 - R562

Is it the first time and is

there a CY1?

M5000 - M5465

R500 - R505

Real outputs Physical outputs

Real values

I1 - I256

O1 - O256

M1 - M2047

Image values

I1 - I256

O1 - O256

M1 - M2047

Logic CNC inputs.

Ye s N o

Loading...

Loading...