Operating manual

CNC 8055

CNC 8055i

PLC

10.

·T· MODEL

SOFT: V02.2X

·187·

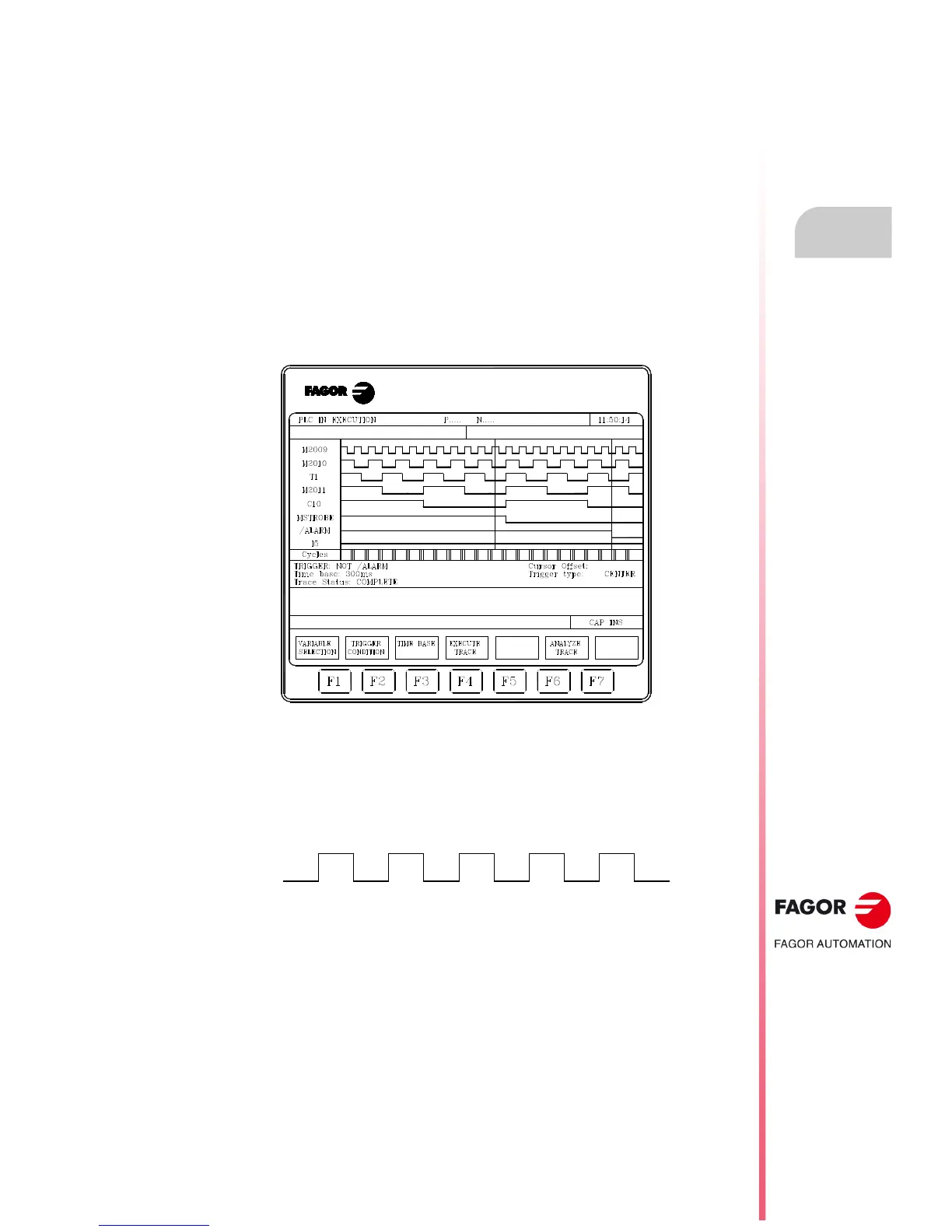

Logic analyzer

10.10 Logic analyzer

The logic analyzer is especially suited to help in the machine start-up and for troubleshooting errors

and critical situations in signal behavior.

This option is used to analyze the behavior of the logic PLC signals according to a time base and

certain trigger conditions set by the user.

Up to 8 signals can be analyzed at the same time. The results are shown using a graphic interface

that makes it easy to interpret the data.

10.10.1 Description of the work screen

The screen for the logic analyzer is divided into the following areas or display windows:

1. Status window.

It graphically shows the status of each selected signal. It is divided into two areas: the variable

area and the status area.

The variables area shows the names or symbols of the logic signals to be analyzed.

The status area shows the status of each variable in square waves. The line for logic level 0 is

shown with a thicker line.

Likewise, it shows a vertical red line to indicate the TRIGGER point and another green vertical

line to indicate the cursor position.

The vertical green line for the cursor may be moved along the trace and helps measure the time

between two points of the trace.

The status area is divided into several vertical stripes. Each stripe represents the amount of time

defined by the "time base" constant.

The "time base" constant sets the resolution of the logic signals and, after being set by the user,

may be modified as often as desired. The "time base" is inversely proportional to the resolution

of the signals; thus, the lower the "time base" the greater the signal resolution and vice versa.

2. Cycles window

This window shows several vertical lines "¦". Each one indicates the instant when the execution

of a new cycle of the PLC program starts.

It permits maintaining a relationship between the flux of the logic signals and the duration of each

PLC execution cycle.

Loading...

Loading...