D1-N Series Servo Drive User Manual Servo Drive Configuration

HIWIN MIKROSYSTEM Corp. 5-35

Step

Figure Description

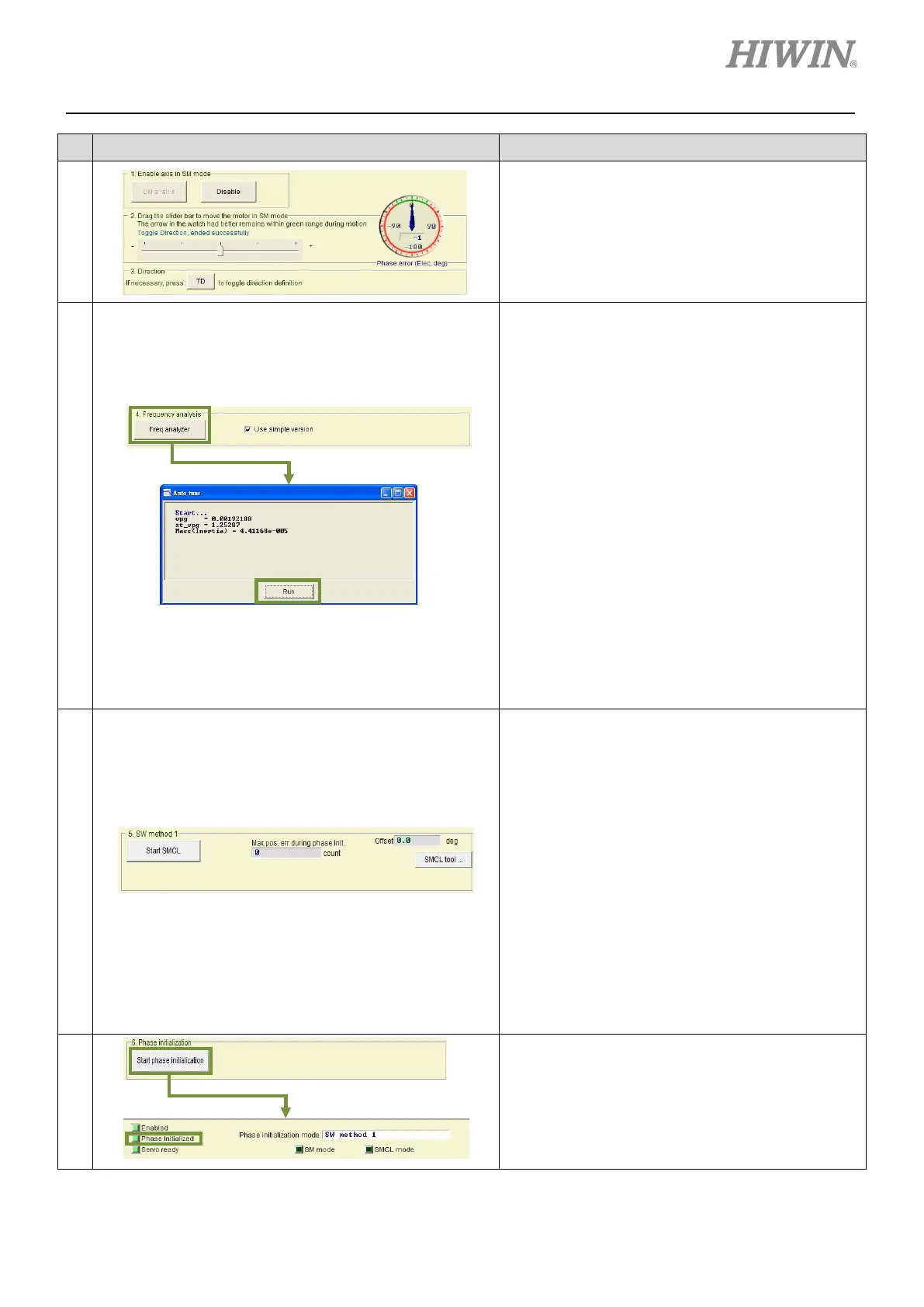

3

Check the definition of motion direction:

If the moving direction is inconsistent with what the

users have defined as forward or reverse direction,

click on TD

button to reverse the definition of

motion direction. After the message “Toggle

Direction, ended successfully” a

step 2 and proceed again.

4

Auto tuning:

Select Use simple version and click on Freq

analyzer button to show Auto tune window. Click

on Run button to analyze frequency response and

calculate parameters.

This function can be used to easily set system loop

gain. But in the following

cases, the calculated

parameter values may not be appropriate for the

system.

(1) The stiffness of the mechanism is too low.

(2) The backlash of the mechanism is too large.

(3) The load has been changed.

(4) The load inertia ratio is over 20.

Note:

(1) If mechanical resonance occurs during execution,

stop inputting Hard

ware enable signal or press

F12 function key (Refer to section 6.1.3).

(2) Users are allowed to tune manually, please refer to

section 10.3. For description of parameters vpg

and st_vpg, please refer to sections

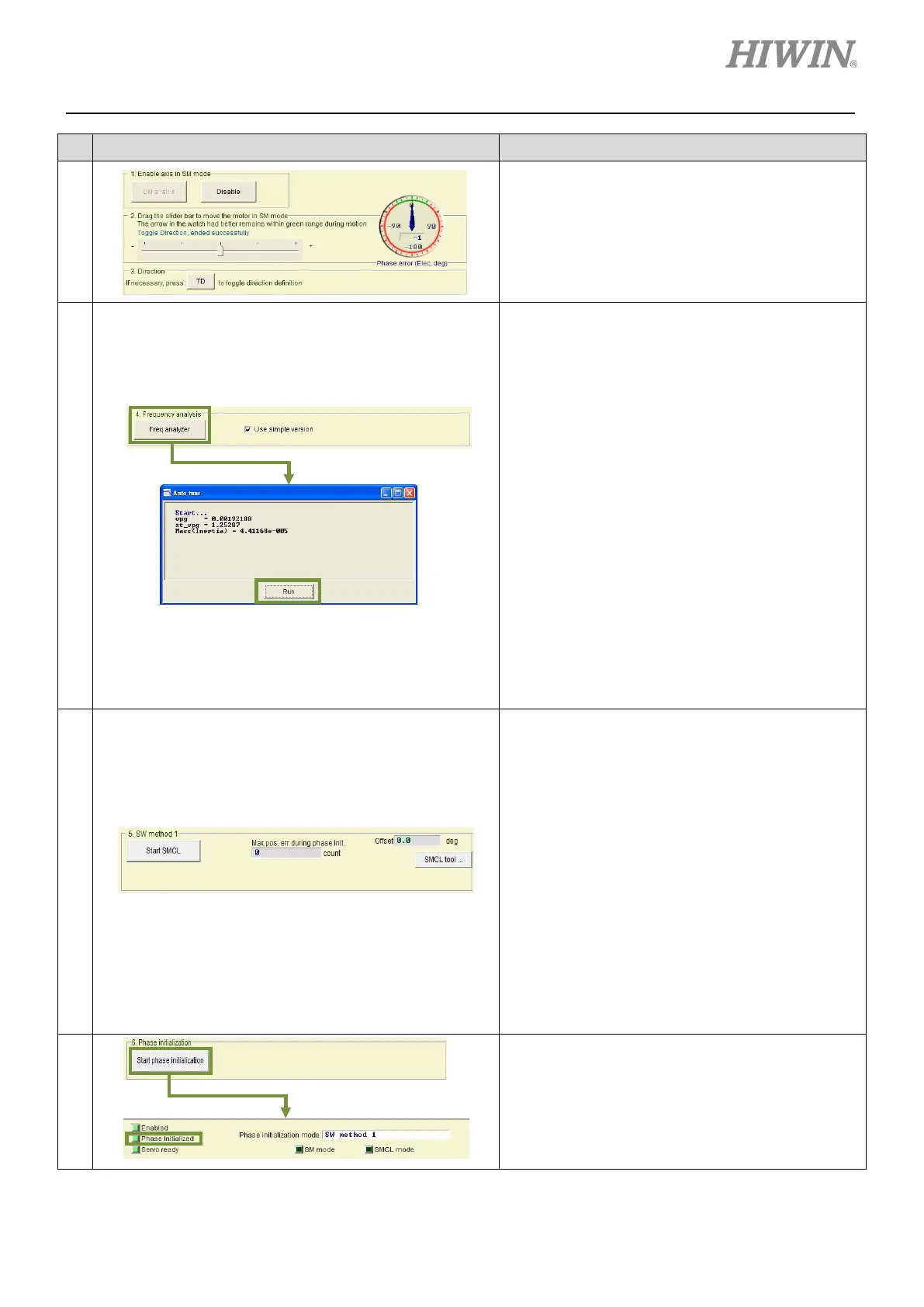

5

Adjusting phase initialization:

By using SW method 1, the motor

move for a small

distance to complete phase

initialization.

After tuning completes in step 4,

confirm the tuning result by the following steps.

Step 1: Click on Start SMCL

electrical angle.

Step 2: Observe the values in the fields of Offset

and Max. pos. err during phase init..

Offset

shows the result of finding

electrical angle and Max. pos. err during

phase init. shows the largest movement

during the process.

Step 3:

Repeat step 1 and 2 to observe if the

offset is within +/- 15 degrees.

Step 4: If offset is too large, click on SMCL tool…

button for advanced tuning.

6

Execute phase initialization:

Click on Start phase initialization button. After

Phase Initialized indicator

means phase initialization

drive is able to control the

closed-loop control.

Loading...

Loading...