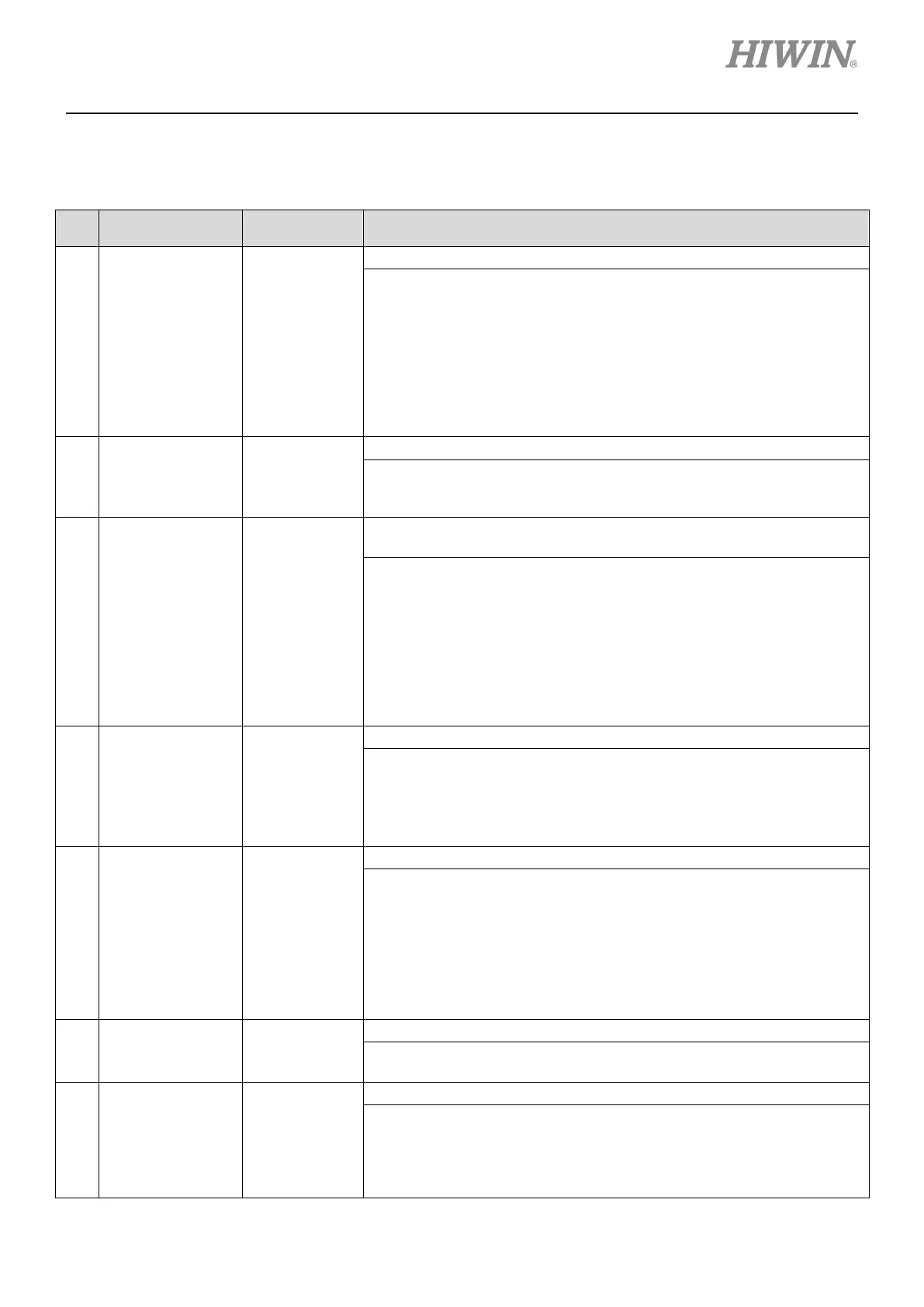

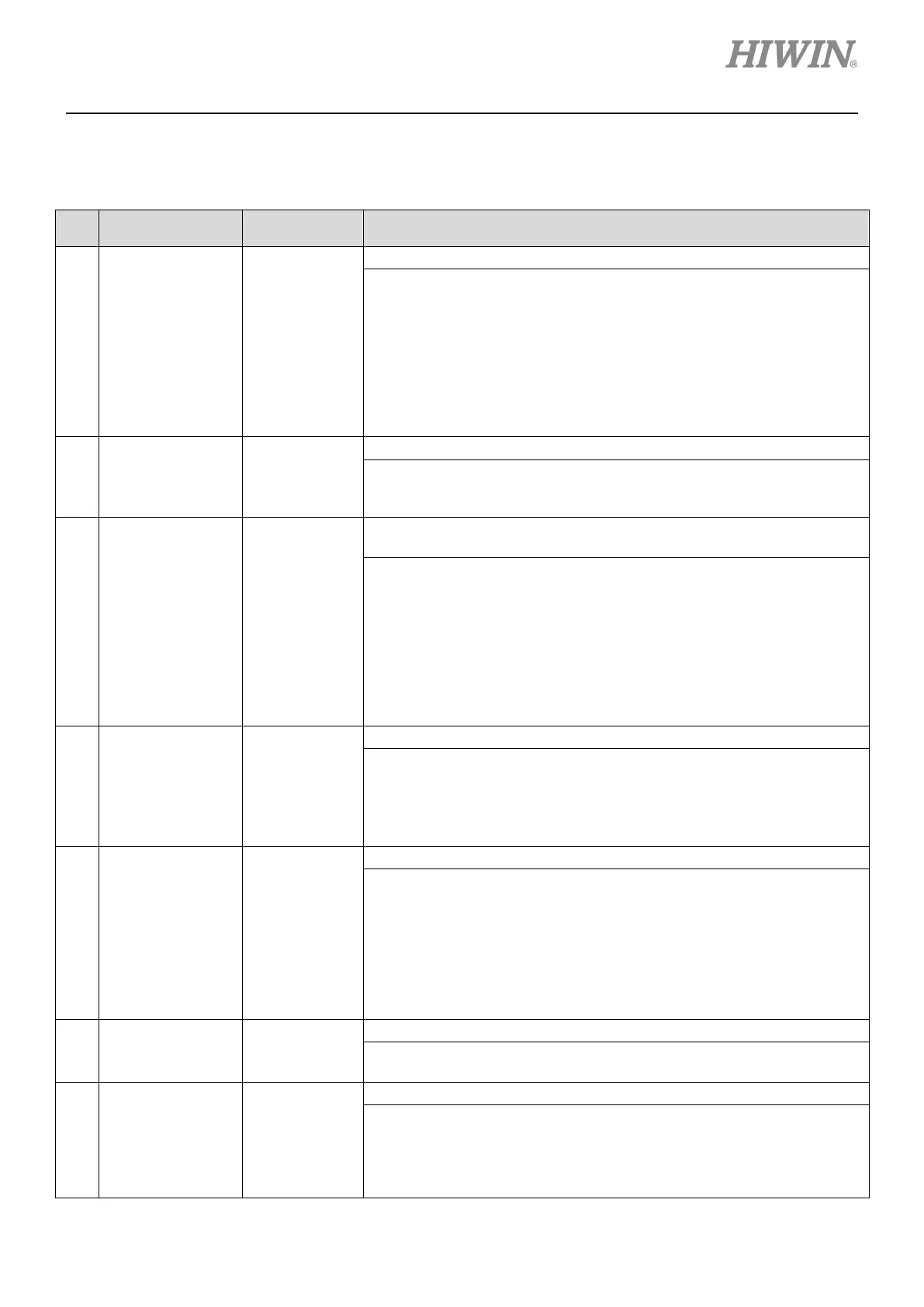

D1-N Series Servo Drive User Manual Errors And Warnings

HIWIN MIKROSYSTEM Corp. 9-3

The errors of D1-N servo drive and their corrective actions are listed in table 9.1.1.

Table 9.1.1

No. Error

Corrective Action

1

Motor short

(over current)

detected

E01 SHORT

or

ERR E01

Three-phase motor power is short-circuited.

(1) Turn off the power of the servo drive and remove the connector of

the

UVW cable from the servo drive. Measure if there is short

circuit between the UVW wires and ground. If short

found, the motor could be burned out.

(2) Measure if the line-to-line resistance between the UVW wires is

close to the required specification. If the resistance is lower than

the required specification, the motor could be burned out.

(3) Remove the motor power cable from the motor, use multimeter to

check if the motor power cable is short-circuited.

2

Over voltage

detected

E02 OVERV

or

ERR E02

DC bus voltage exceeds the limit.

If the motor is running with heavy load at high speed, the back EMF

could exceed the voltage limit. Check if regenerative resistor is needed.

Select regenerative resistor according to load and application.

3

Position error

too big

E03 PEBIG

or

ERR E03

Position error is greater than the setting value of Maximum pos error

for motion protection.

(1) Check if the gain tuning is appropriate.

(2) Check if the value of Maximum pos error

Protection tab of Application center.

(3) Check if the motor is obstructed during motion.

(4) Check if the load is too heavy.

(5) Check if the guideway has not been maintained for a long time.

(6) Check if the cable tray is too tight.

(7) If warning “W05 SVBIG” continuous

ly occurs before error E03,

please change the power supply from 110 V to 220 V.

4 Encoder error

E04 ENCOD

or

ERR E04

Abnormal encoder signal or alarm pin reports an error.

(1) Check if all the encoder connectors are firmly connected.

(2) Check if the wiring of the encoder is correct.

(3) If digital encoder is used, the error could be caused by external

interference. Check if the encoder cable is mad

anti-interference braided wires and shield. Or add on core.

5

Soft-thermal

threshold

reached

E05 SWHOT

or

ERR E05

Motor overload (Software detects motor over temperature.)

(1) Check if the continuous current and instantaneous current of the

motor is within its specification during operation.

(2) Check if the motor is obstructed during motion.

(3) Reset the servo drive and enable the motor again to clear this

error. But if over current is caused by load or motion parameters, it

could happen again.

(4) Decrease speed, acceleration and deceleration.

(5) Check if the motor model or motor current is correctly set.

6

Motor maybe

disconnected

E06 UVWCN

or

ERR E06

Motor power cable and servo drive are not firmly connected.

(1) Check if the connector of the UVW cable is firmly connected.

(2) Check if the motor model is correctly set.

7

Amplifier over

temperature

E07 D.HOT

or

ERR E07

Servo drive over temperature

(1) Check if the servo drive is installed in well-ventilated location.

(2) Check if the ambient temperature is too high.

(3) Wait till the servo drive cools down.

(4) If the servo drive has been used with heavy load or for a long

operating time, check if heat sink is needed.

Loading...

Loading...