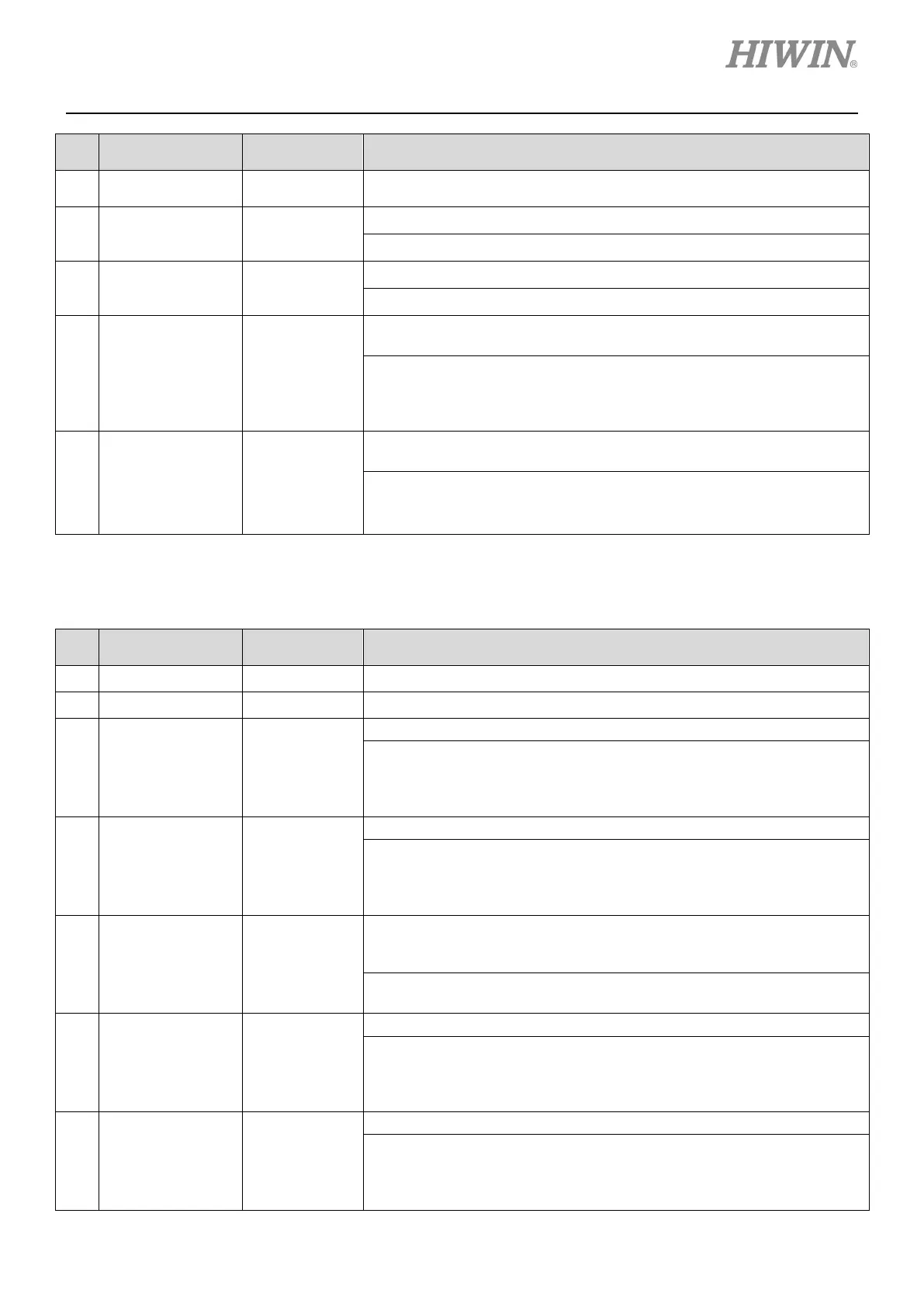

D1-N Series Servo Drive User Manual Errors And Warnings

HIWIN MIKROSYSTEM Corp. 9-5

No. Error

Corrective Action

Check if all the cables are properly grounded.

20

Auto phase center

not complete error

or

Phase initialization is not completed yet.

Execute all the procedures in Auto phase center again.

22

DC bus voltage

abnormal

or

DC bus voltage is abnormal.

Check the input voltage.

23

EtherCAT

interface is not

detected

E23NOET

or

ERR E23

Servo drive does not detect EtherCAT interface or servo drive has no

EtherCAT interface.

(1) Turn off the power of the servo drive. Power on the servo drive to

detect EtherCAT interface again.

(2) The servo drive does not support EtherCAT. Check if the servo

24

CiA-402 homing

error

E24HOM.E

or

ERR E24

An error occurs when performing CiA-402 homing and causes homing

(1) Check if left limit, right limit, near home sensor and index signal

are normal.

(2) Check if the selected homing method is appropriate.

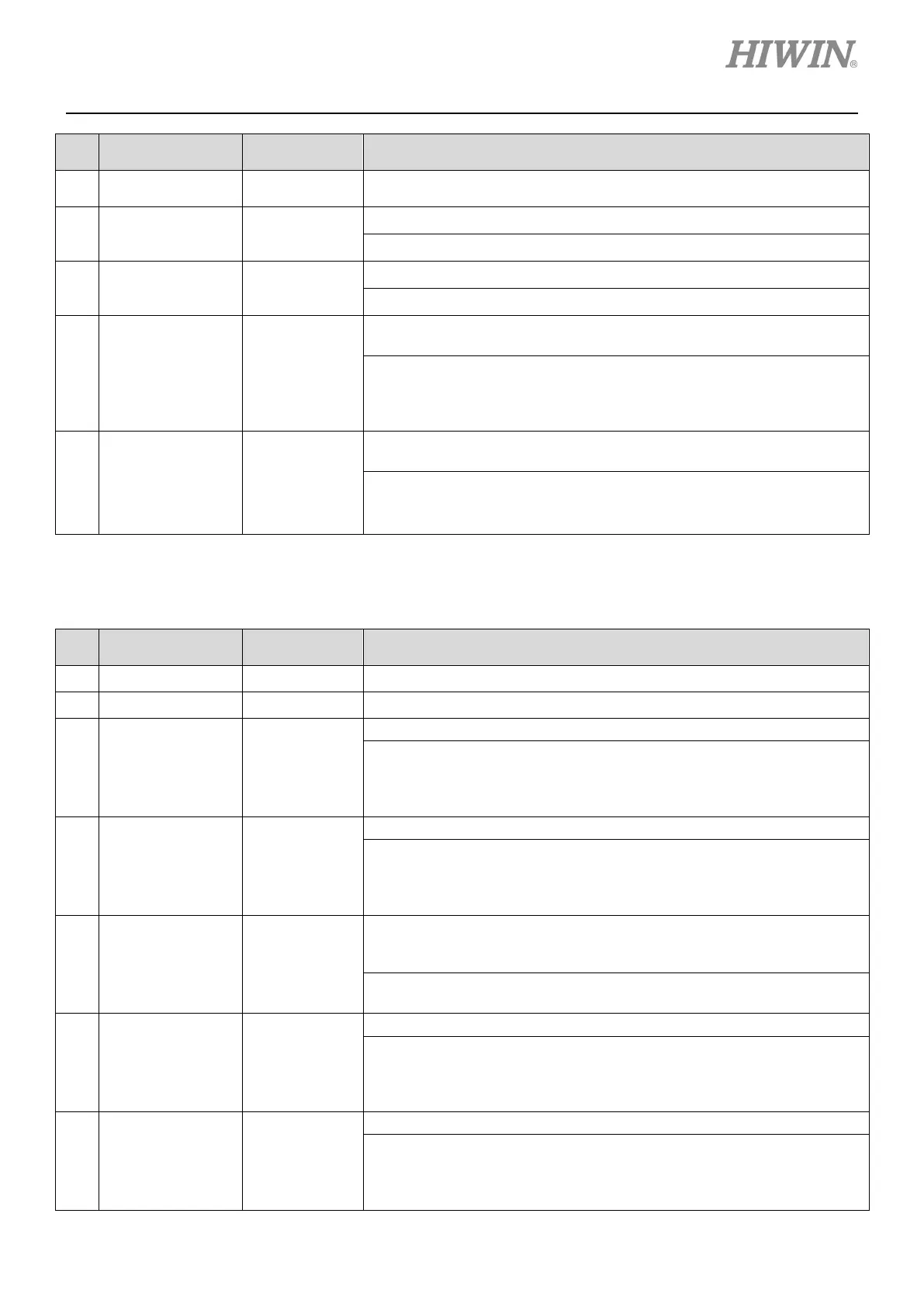

The warnings of D1-N servo drive and their corrective actions are listed in table 9.1.2.

Table 9.1.2

No. Error

Corrective Action

1 Left SW limit WRN W01 The left software limit is reached. The motor cannot move leftward.

2 Right SW limit WRN W02 The right software limit is reached. The motor cannot move rightward.

3 Left HW limit WRN W03

Left hardware limit is triggered. The motor cannot move leftward.

(1) If no hardware limit exists, please disable the function of hardware

limit.

(2) If it is a false trigger, please check if the wiring or logic setting is

4 Right HW limit WRN W04

Right hardware limit is triggered. The motor cannot move rightward.

(1) If no hardware limit exists, please disable the function of hardware

limit.

(2) If it is a false trigger, please check if the wiring or logic setting is

5

Servo voltage

big

WRN W05

The PWM output switch is greater than the limit value. The current

output cannot be increased anymore. If this warning continuously

occurs in position control, error “E03 PEBIG” may occur.

(1) Change power supply from 110 V to 220 V.

(2) Decrease speed, acceleration or deceleration.

6

Position error

warning

WRN W06

Position error is greater than the value set for warning.

(1) Check if the servo gain is properly set.

(2) Check if the warning threshold is set to be too small.

(3) Check if the mechanism has been maintained regularly

or the

mechanism is lack of lubrication.

7

Velocity error

warning

WRN W07

Velocity error is greater than the value set for warning.

(1) Check if the servo gain is properly set.

(2) Check if the warning threshold is set to be too small.

(3)

Check if the mechanism has been maintained regularly or the

mechanism is lack of lubrication.

Loading...

Loading...