5 General concepts

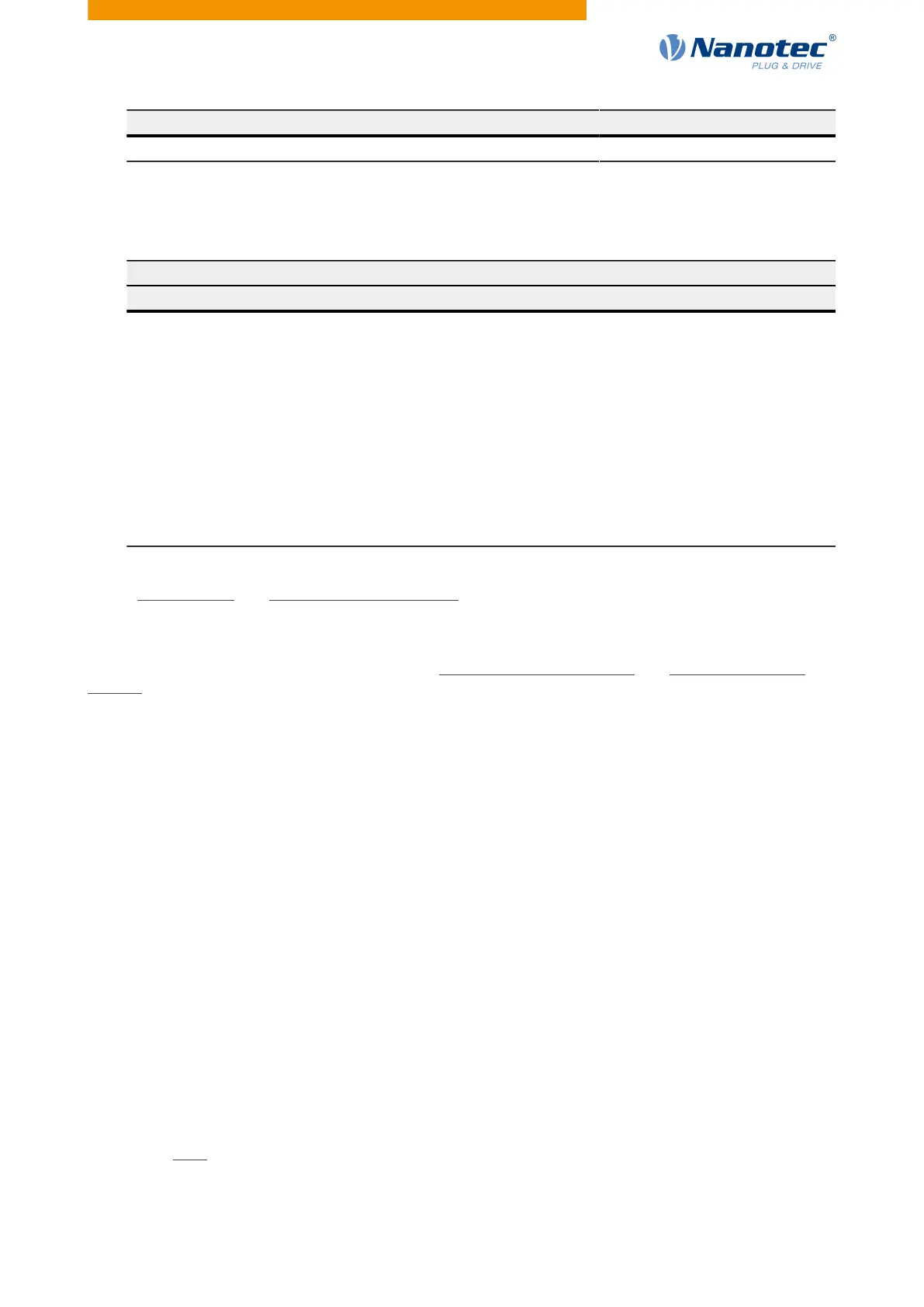

Feedback Stepper motor BLDC motor

Sensorless yes yes

Various operating modes can be used depending on the control mode. The following list contains all the

types of operation that are possible in the various control modes.

Operating mode Control mode

Open Loop Closed Loop

Profile Position yes yes

Velocity yes yes

Profile Velocity yes yes

Profile Torque no

1)

yes

Homing yes

2)

yes

Interpolated Position Mode yes

3)

yes

Cyclic Synchronous Position yes

3)

yes

Cyclic Synchronous Velocity yes

3)

yes

Cyclic Synchronous Torque no

1)

yes

Clock-direction yes yes

1) The Profile Torque and Cyclic Synchronous Torque torque operating modes are not possible in the open

loop control mode due to a lack of feedback.

2) Exception: Homing on block is not possible due to a lack of feedback.

3) Because ramps and speeds in operating modes Cyclic Synchronous Position and Cyclic Synchronous

Velocity follow from the specified points of the master, it is not normally possible to preselect these

parameters and to ascertain whether a step loss can be excluded. It is therefore not advisable to use these

operating modes in combination with open loop control mode.

5.1.2 Open Loop

5.1.2.1 Introduction

Open loop mode is only used with stepper motors and is, by definition, a control mode without feedback. The

field rotation in the stator is specified by the controller. The rotor directly follows the magnetic field rotation

without step losses as long as no limit parameters, such as the maximum possible torque, are exceeded.

Compared to closed loop, no complex internal control processes are needed in the controller. As a result,

the requirements on the controller hardware and the controller logic are very low. Open loop mode is used

primarily with price-sensitive applications and simple movement tasks.

Because, unlike closed loop, there is no feedback for the current rotor position, no conclusion can be drawn

on the counter torque being applied to the output side of the motor shaft. To compensate for any torque

fluctuations that arise on the output shaft of the motor, in open loop mode, the controller always supplies the

maximum possible (e.g., specified by parameters) set current to the stator windings over the entire speed

range. The high magnetic field strength thereby produced forces the rotor to assume the new steady state in

a very short time. This torque is, however, opposite that of rotor's inertia. Under certain operating conditions,

this combination is prone to resonances, comparable to a spring-mass system.

5.1.2.2 Commissioning

To use open loop mode, the following settings are necessary:

●

In object 2030

h

(Pole Pair Count), enter the number of pole pairs (see motor data sheet: for a stepper

motor with 2 phases, a step angle of 1.8° corresponds to 50 pole pairs and 0.9° corresponds to 100 pole

pairs).

Version: 2.0.1 / FIR-v1650 34

Loading...

Loading...