Trainee Guide TR-L2-M2000

Level 2 Maintenance Training - M2000 Dispensing Systems 3-2-23 P/N 73-0018-00 (Revision B)

Information Sheet 3-6-2

Valve Maintenance (Continued)

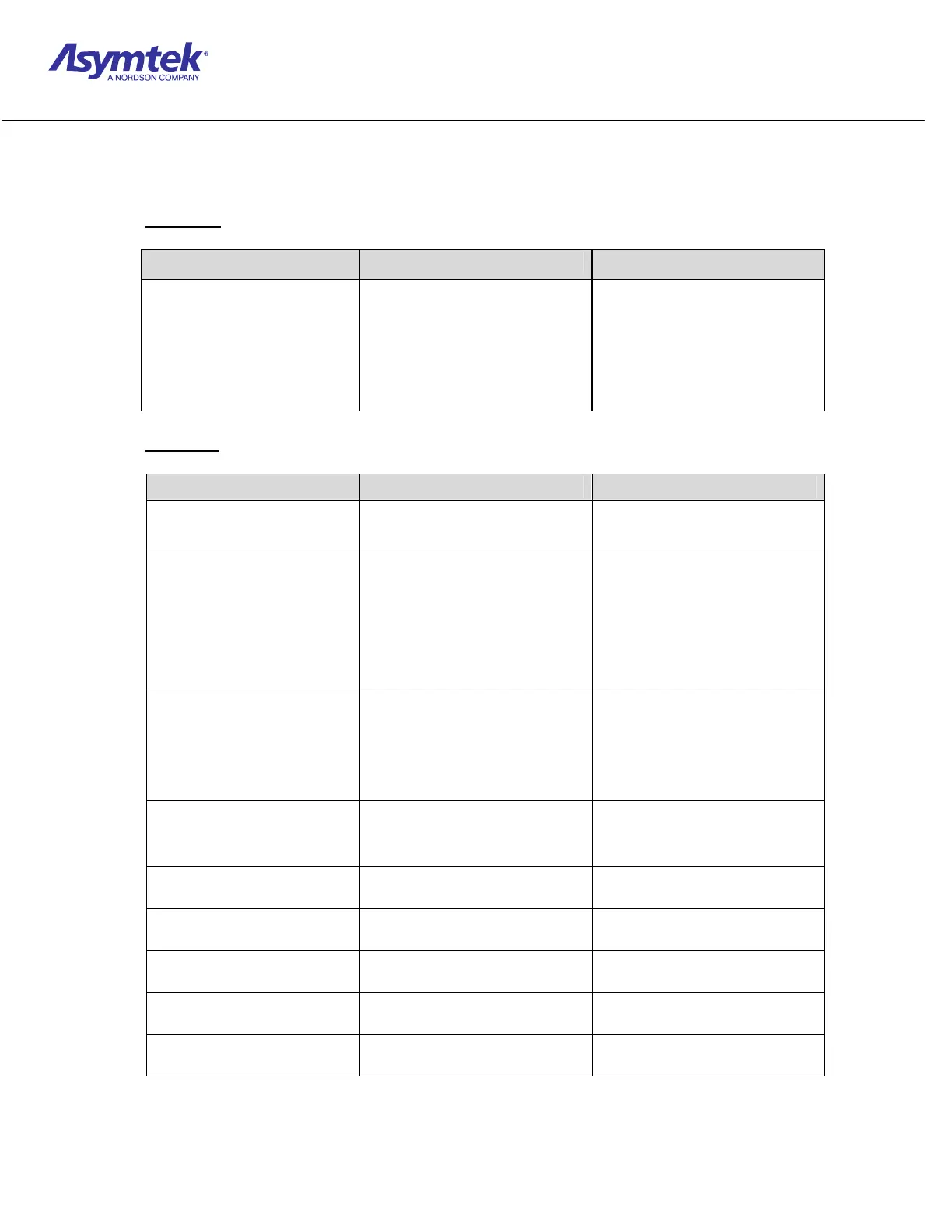

C. DV-7000

Maintenance Procedure Recommended Frequency Instructions

Clean exterior and interior

exposed surfaces of the

pump.

Clean daily.

Clean before using new

fluid.

Clean immediately after

using curable material.

If needle tip is clogged

See Exercise Sheet 3-6-8

on page 3-2-38.

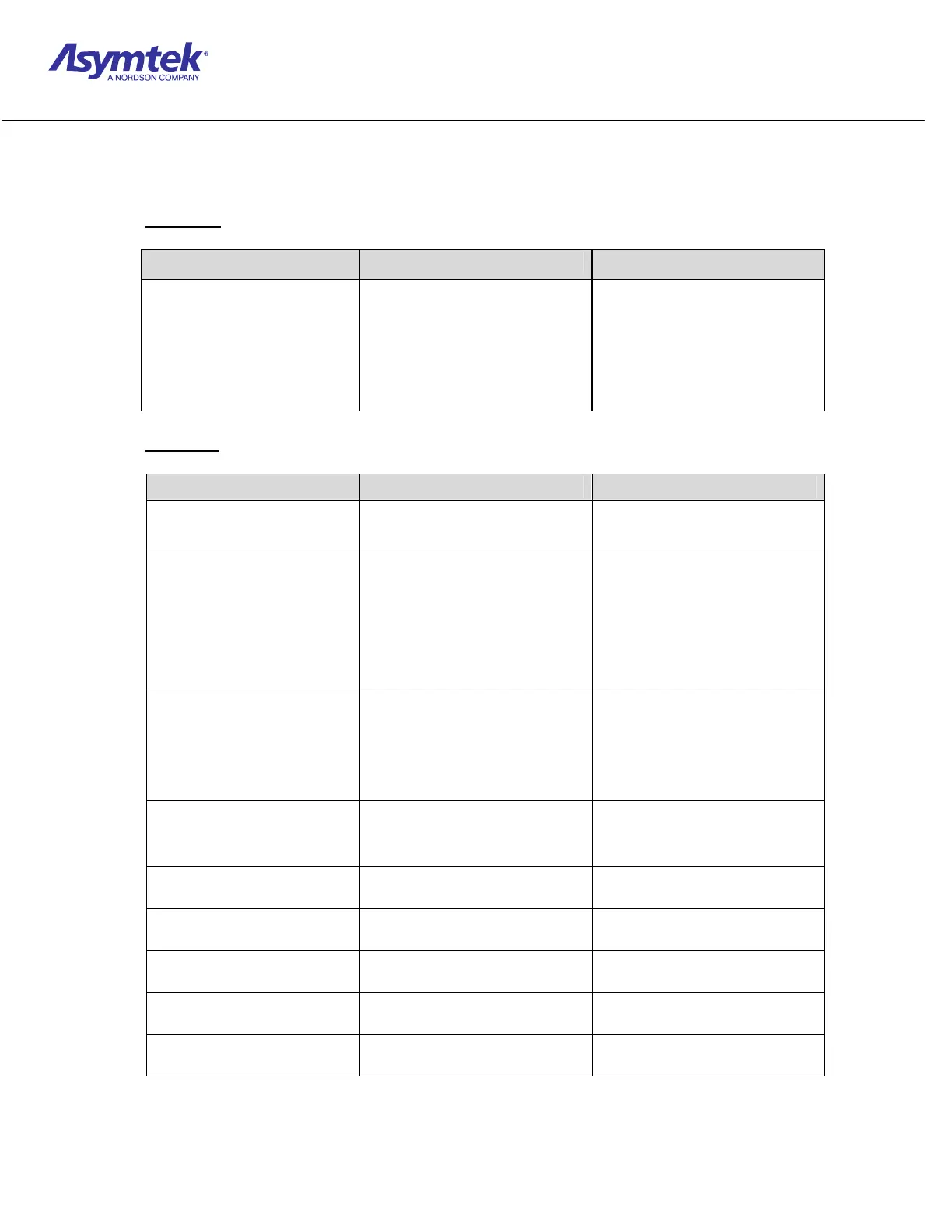

D. DJ-2000

Maintenance Procedure Recommended Frequency Instruction

Quick Purge

Change of Syringe

Each dispensing session

See DJ-2000 Installation and

Operations Manual

Priming

DJ-2000 Installation

Cleaned or disassemble

pump

Dots are inconsistent or

pump is unable to

dispense fluid

See DJ-2000 Installation and

Operations Manual

Complete Cleaning

After each session.

Change of Fluid Type

Troubleshooting

Immediately after using

curable material.

See Exercise Sheet 3-6-11

on page 3-2-44.

Clean Nozzle

After each dispensing

session

Every eight hours of use

See Exercise Sheet 3-6-11

on page 3-2-44.

Fluid U-Cup Seal

Replacement

Normal Use

20-25 million cycles*

See DJ-2000 Installation and

Operations Manual

Needle, Extension

Replacement

Normal Use

40-50 million cycles

See DJ-2000 Installation and

Operations Manual

Air Piston Replacement

Normal Use

40-50 million cycles

See DJ-2000 Installation and

Operations Manual

Spring, Micrometer

Replacement

Normal Use

40-50 million cycles

See DJ-2000 Installation and

Operations Manual

Adjusting Air Piston

Assembly

a. Normal Use

After complete cleaning

See DJ-2000 Installation and

Operations Manual

Loading...

Loading...