Trainee Guide TR-L2-M2000

Level 2 Maintenance Training – M2000 Dispensing Systems 4-2-25 P/N 73-0018-00 (Revision B)

Information Sheet 4-8-2

DP-3000 Troubleshooting (Continued)

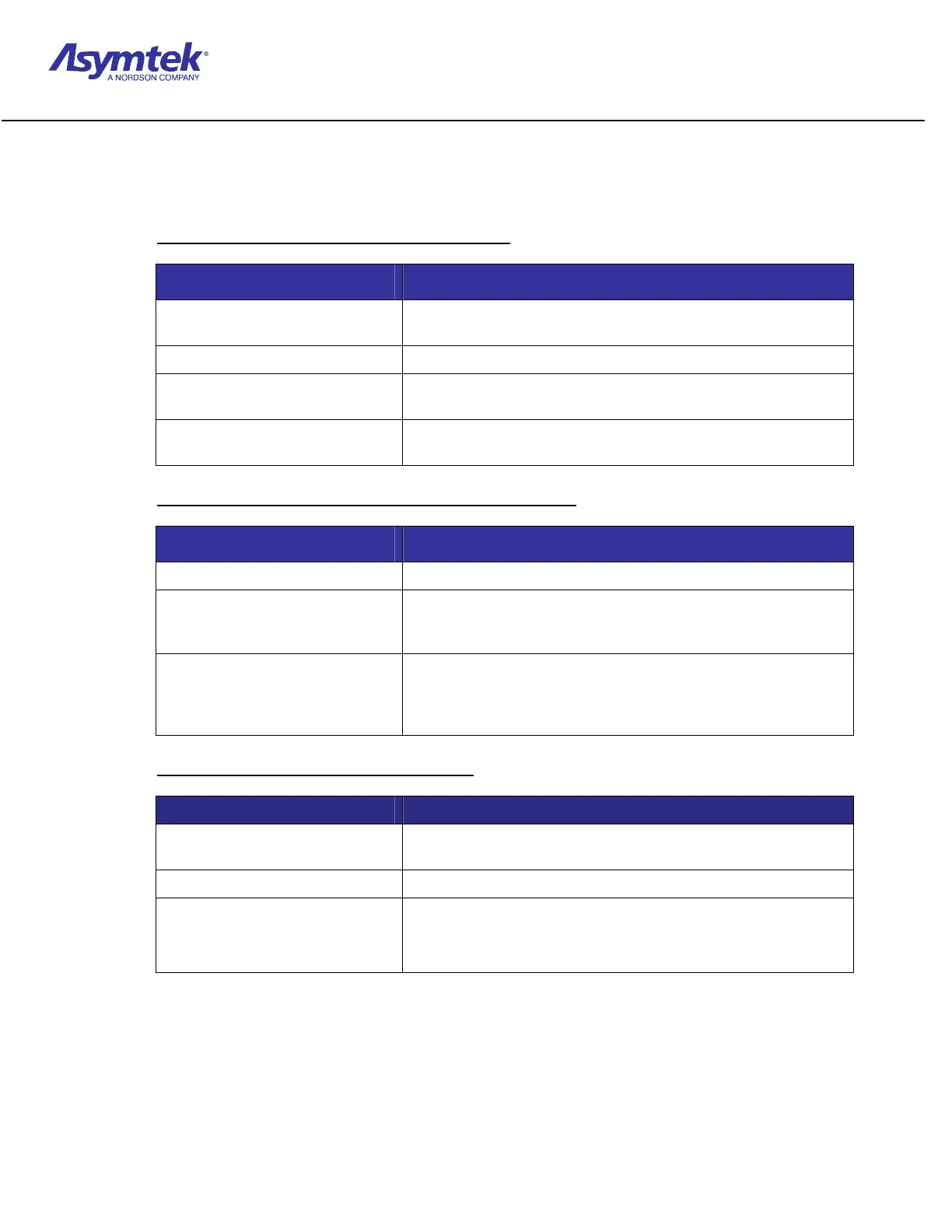

E. Pump Unable To Complete Reset Routine

Possible Cause Recovery

1. Pump air pressure too low

1. Set valve pressure to 40-80 psi.

(For encoded models, set the fluid pressure to 40 psi).

2. Speed Control too slow 2. Make sure Speed Control is greater than 1.

3. Stopcock jammed with

cured material

3. Replace the stopcock.

4. Stopcock Cylinder

Adjustment Screw too tight.

4. Loosen the Stopcock Cylinder Adjustment Screw.

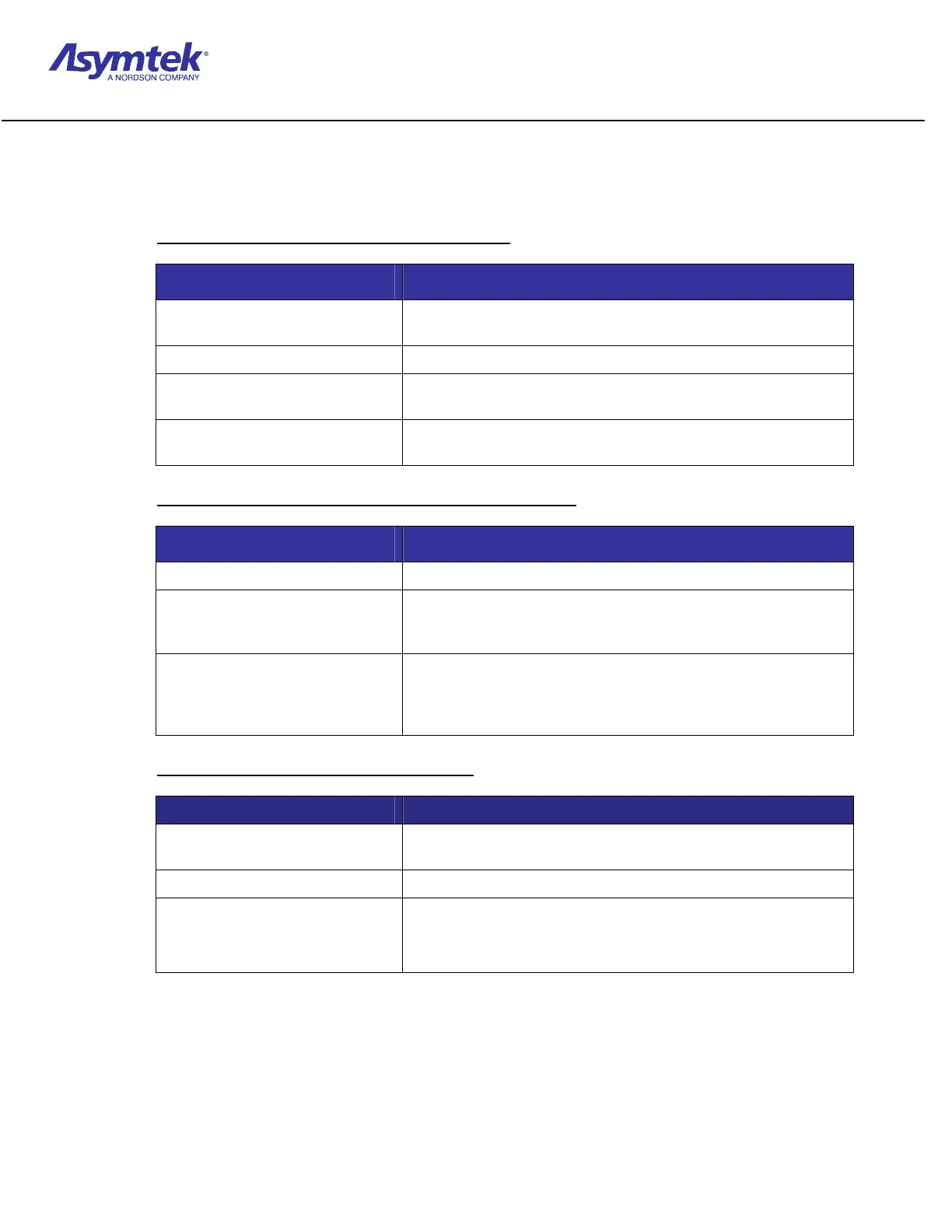

F. Material Drips Or Trails Slightly From The Needle

Possible Cause Recovery

1. Air in chamber 1. Perform a priming sequence.

2. Fluid is slightly

compressible or

stopcock is expanding

2. Use a larger diameter needle.

3. Stopcock cylinder

adjustment screw is

improperly adjusted (non-

encoded version only).

3. Turn the stopcock cylinder adjustment screw clockwise so

that the stopcock moves from the refill position to the

dispense position more slowly. Typically, it should be

adjusted so that it takes 2 seconds for this motion.

G. Pump Not Dispensing Or Responding

Possible Cause Recovery

1. Piston is out of sensor

range

1. See “Feed Screw Jam Recovery” in DP-3000 Operations

Manual.

2. No power to motor 2. Refer to Information Sheet 4-8-1.

3. DP-3000 has reached its

Travel Limit

1. In the Main Window, click on Run a Program.

2. Click on Setup, and then select DP-3000 −

−−

− Refill.

3. Return to the Main Window.

Loading...

Loading...